ADAS SENSOR SUITE DESIGN SERIES: FRONT END

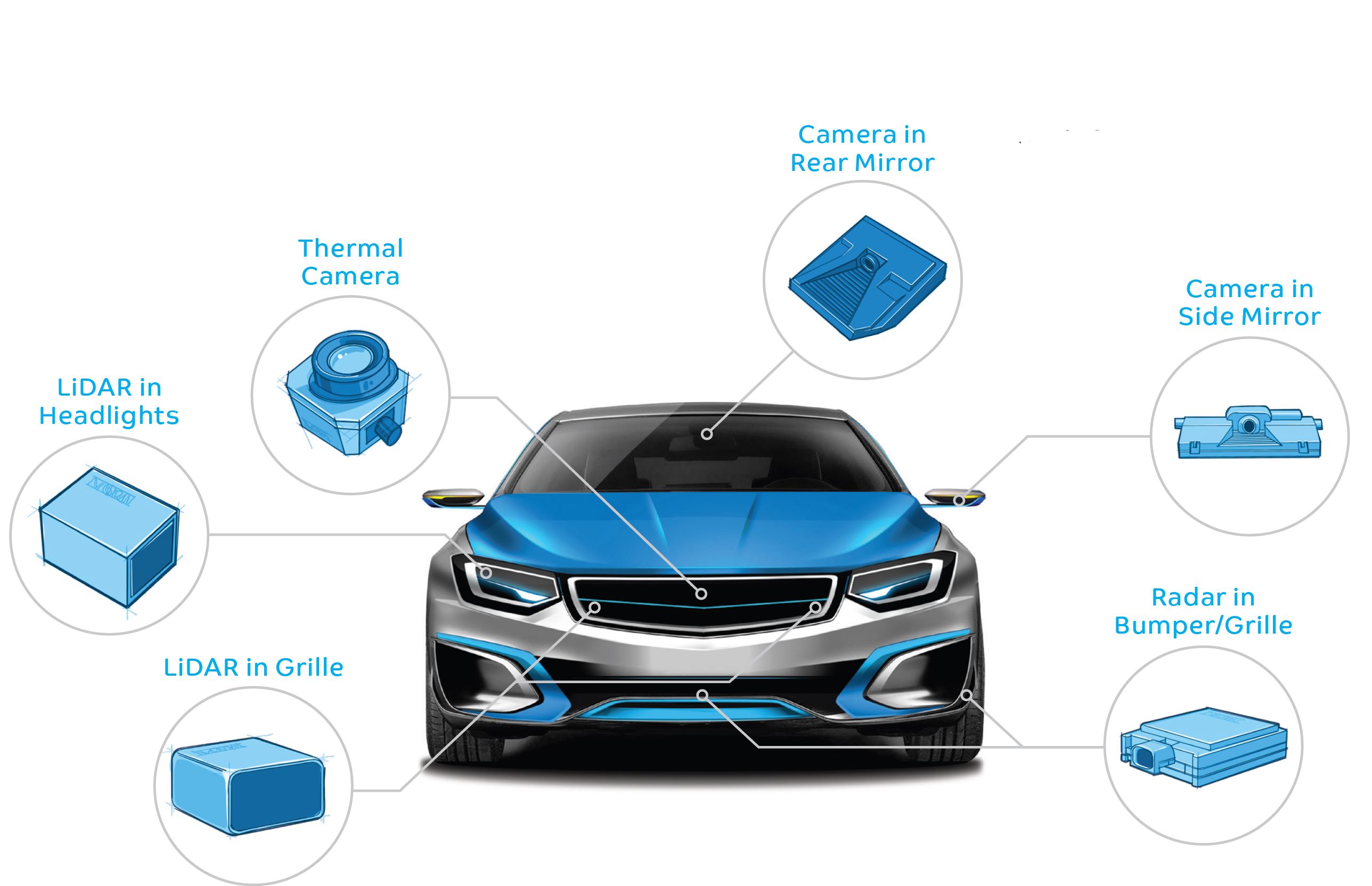

Most new vehicles today are equipped with driving assistance systems (ADAS) that handle functions such as blind spot protection, park assist, and adaptive cruise control. What is still to be determined is the perfect configuration and location of ADAS componentry. OEM and Tier design engineers face the challenge of balancing vehicle aesthetics and achieving a reliable, safety-redundant sensor suite. Whether the decision is to integrate LiDAR into the lighting system or adding a thermal camera into the grille, material selection for ADAS componentry is a key step in the design process.

The front end of the automobile is an area of significant design opportunity to configure the optimal layout for the ADAS sensing suite. SABIC’s Mobility team has a history of innovating and guiding customers through the material selection process. SABIC’s highly specialized engineered thermoplastic solutions can offer an array of effects such as thermal conductivity, EMI shielding, and visual opacity with IR transparency to increase design flexibility while maintaining needed visuals. SABIC’s Global Application Technology team offers simulation and modeling analyses to help identify component integration opportunities and design optimization. Below are only a few of the significant attributes our materials could bring to your application:

ULTEM™ RESIN

- IR transparency with visual opacity

- Excellent dimensional stability

- UV, hydrolytic and chemical resistance

- Superior heat resistance

NORYL GTX™ RESIN

- Excellent impact and chemical resistance

- Low moisture uptake

- Low warpage

- UV property retention

LNP™ COPOLYMERS & COMPOUNDS

- EMI shielding

- Radar absorption

- Low warpage

- Thermal conductivity

- High optical clarity & heat resistance

TECHNICAL CENTER LOCATIONS & CONTACT INFORMATION

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience