ADAS SENSOR SUITE DESIGN SERIES: REAR DETECTION

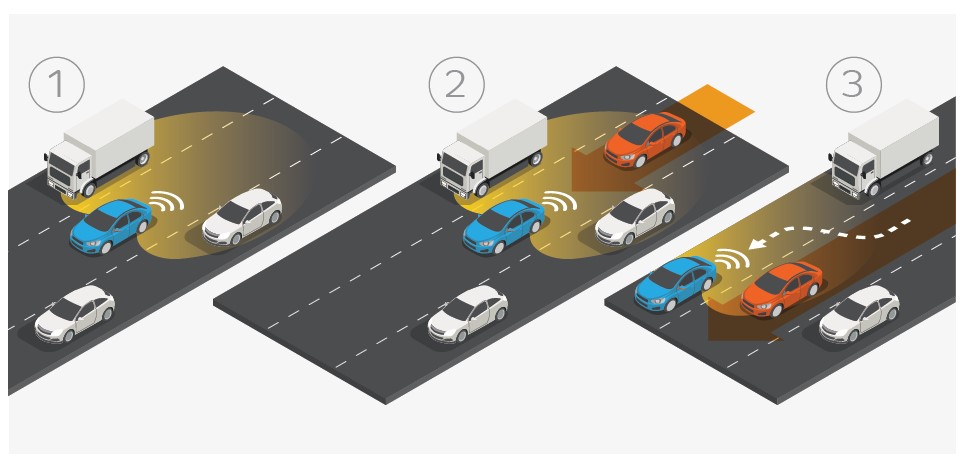

The previous two editions of the ADAS Sensor Suite Design Series (front-end & interior monitoring), forecasted that the future of the ADAS sensor suite will embody a full external and internal view of the vehicle, its occupants and its surroundings. It is equally clear that the rear facing implementation of this sensor suite is becoming an increasing area of focus for automotive OEMs and tiers. Implementing a rear-collision based ADAS system is another enabler of proactive and protective measures to enhance the safety of the driver and passengers of the impacted vehicle. Such features could include adjustments to the driver's seating position, automatic closing of the windows and sunroof, pre-tensioning of the seatbelt systems, automatic triggering of hazard lights, and warnings allowing the driver to change lanes if safe to do so.

ADAS systems, regardless of location, will need to incorporate styling as desired by OEMs and will require specific material functionalities, i.e. radar absorption from materials such as LNPTM STAT-KON™ compound; the IR transparency and high heat resistance provided by ULTEM™ resin, or the high dimensional stability performance of NORYL GTX™ resin: see page 2 for a full product line card. SABIC has the experience and technical knowledge to assist your team through the stages of system design, prototyping and testing. We invite you to contact one of our technical centers to learn more about the benefits of our LNP™ copolymers and compounds, and our NORYL™ and ULTEM™ resins, as well as our application development services that include material recommendations and sampling, tooling review and design suggestions, material data for design simulations, onsite technical support for mold trials and processing troubleshooting.

PRODUCT LINE CARD

NORYL™ resin

Modified PPE/HIPS

• Amorphous, reinforced & un-reinforced, additives

• Good room temp. & low temp. Impact strength

• Excellent hydrolytic stability

• Low specific gravity

• Heat resistance to 149 °C

• Strong electrical and flame resistance properties

ULTEM™ resin

PEI

• High heat resistance to 221 °C

• Exceptional unfilled strength and stiffness

• Great isotropic dimensional stability

• Excellent UV, hydrolytic & chemical stability

• Near Infrared transparency

• Robust electrical & dielectric properties

• Inherent flame retardancy / low smoke generation

• Outstanding optical properties

• Mirror like, direct vacuum metallization

• Low outgassing, high haze onset temps

• UL RTI up to 180 °C

EXTEM™ resin

TPI

• Superior Heat resistance to 255 °C

• Near Infrared transparency

• Lead free solder capable up to 260 °C

per JEDEC reflow

SILTEM™ resin

Siloxane polyetherimide block copolymer

• Low modulus, flexible

• Non-Br & Cl flame retardancy

• Robust electrical & dielectric properties

• Solid heat resistance to 164 °C

NORYL™ GTX

PPE/Polyamide

• Amorphous/crystalline blend, reinforced

& un-reinforced

• Good chemical resistance

• Dimensional stability

• Heat resistance to 240 °C

• Excellent impact

• Electrostatic painting & powder coating

LEXAN™ EXL resin

High impact PC/Siloxane copolymer

• Excellent low temperatures impact

• Weatherability

• Improved chemical resistance

• Excellent processability

• Impact retention upon long term

heat and humidity aging

• Non-Br & Cl flame retardant grades

• Wide range of colors including

• VISUALFX™ resin

LEXAN™ SLX resin

Weatherable PC copolymer

• Extreme weatherability—prolonged UV exposure (>10yr)

• Cost reduction through paint-free, MIC

• Clarity: low haze, high light transmission

• Lower gloss loss and color shift

• High heat and impact performance

• Higher flow SLX to enable thinner wall designs and benefits for cost savings

LEXAN™ XHT resin, CXT resin, and PPC resin

High Heat PC copolymer

• Heat resistance in range of 140-180 °C

• Outstanding surface finish and primer-less metallization

• High flow XHT to enable thinner wall designs

• CXT resin: highest heat resistance (up to 190 °C) with higher clarity vs. XHT resin

• PPC resin: heat resistance (up to 165 °C ) and impact performance

LNP™ LUBRICOMP™/LUBRILOY™ compound

• Lubrication

• Durability

• Noise abatement

• Low maintenance

LNP™ STAT-KON™/STAT-LOY™ compound

• Anti-static

• Electro-static dissipation

LNP™ THERMOCOMP™ /THERMOTUF™ compound

• Dimensional accuracy

• High modulus & ductile

• Super structural

• Metal replacement

• NMT (nano molding)

• Tunable dielectric solution (dk / df)

• Solutions that focus on sustainability

LNP™ FARADEX™ compound

• EMI/RFI shielding

LNP™ KONDUIT™ compound

• Thermal dissipation

LNP™ VERTON™ compound

• High modulus

• Excellent impact at all temperatures

TECHNICAL CENTER LOCATIONS & CONTACT INFORMATION

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

Any sale by SABIC, its subsidiaries and affiliates (each a “seller”), is made exclusively under seller’s standard conditions of sale (available upon request) unless agreed otherwise in writing and signed on behalf of the seller. While the information contained herein is given in good faith, SELLER MAKES NO WARRANTY, EXPRESS OR IMPLIED, INCLUDING MERHCHANTABILITY AND NONINFRINGEMENT OF INTELLECTUAL PROPERTY, NOR ASSUMES ANY LIABILITY, DIRECT OR INDIRECT, WITH RESPECT TO THE PERFORMANCE, SUITABILITY OR FITNESS FOR INTENDED USE OR PURPOSE OF THESE PRODUCTS IN ANY APPLICATION. Each customer must determine the suitability of seller materials for the customer’s particular use through appropriate testing and analysis. No statement by seller concerning a possible use of any product, service or design is intended, or should be construed, to grant any license under any patent or other intellectual property right. SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates, unless otherwise noted.

© 2023 Saudi Basic Industries Corporation (SABIC). All Rights Reserved.

SABIC and brands marked with TM are trademarks of SABIC or affiliates.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience