DRINKING WATER APPLICATIONS

DRINKING WATER APPLICATIONS UP TO 85°C

NORYLTM RESIN AS A ROBUST ALTERNATIVE TO PA 6.6

The new mandatory German drinking water evaluation criteria KTW-BWGL is effective as of March 2021. End-use parts and components in contact with potable water and sold in German market will need to comply with the new regulations.

Meeting new KTW-BWGL has become challenging for various materials commonly used in hot water applications (up to 85°C) such as glass filled polyamide 6.6 (GF PA 6.6).

OUR POTENTIAL SOLUTION

Our NORYL global potable water resins portfolio provides a robust alternative which is not only compliant with KTW-BWGL but also can provide additional benefits such as more parts per kilogram and long-term property retention at elevated temperatures and chemical exposure. Our team of experts is ready to assist you during the transition process to our GF resins with tooling and processing support, and our advanced design and simulation capabilities to optimize parts so they can address your performance requirements.

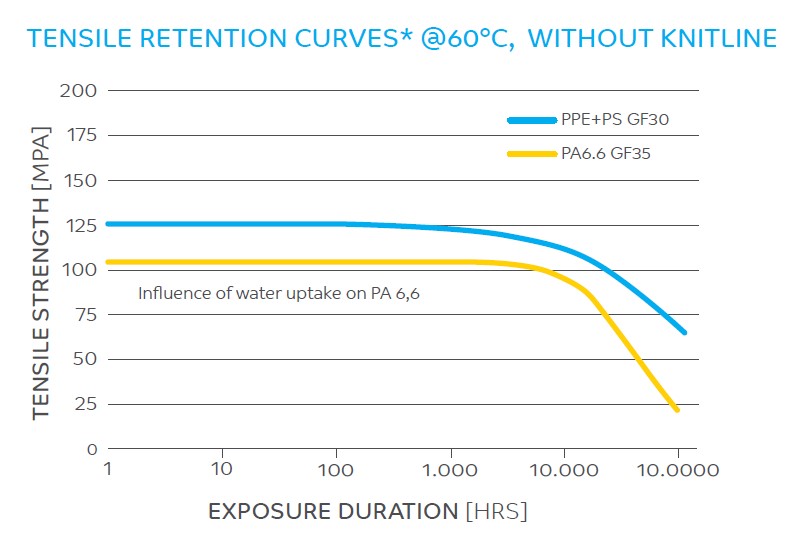

PROPERTY RETENTION

NORYL glass filled (GF) resins show excellent dimensional stability when exposed to water at elevated temperature,

as result of very low water uptake. NORYL GF resins have less than 0.3% water uptake when exposed to 90°C water

compared to 5.3% for 35%GF PA 6.6. High water uptake is something that can negatively influence material

properties and need to be carefully considered during design stage. Long-term hydrolytic stability and good

property retention when exposed to elevated temperature is another key benefit for NORYL GF resins.

Excellent resistance against chlorine at elevated temperatures is another benefit for NORYL GF resins which

help ensure long-term property retention.

PROCESSING AND TOOLING CONSIDERATIONS

Key aspects to consider when using NORYL TM GF resin in existing PA 6.6 mold are:

• Melt and mold temperature are in the same range for GF NORYL and PA 6, 6

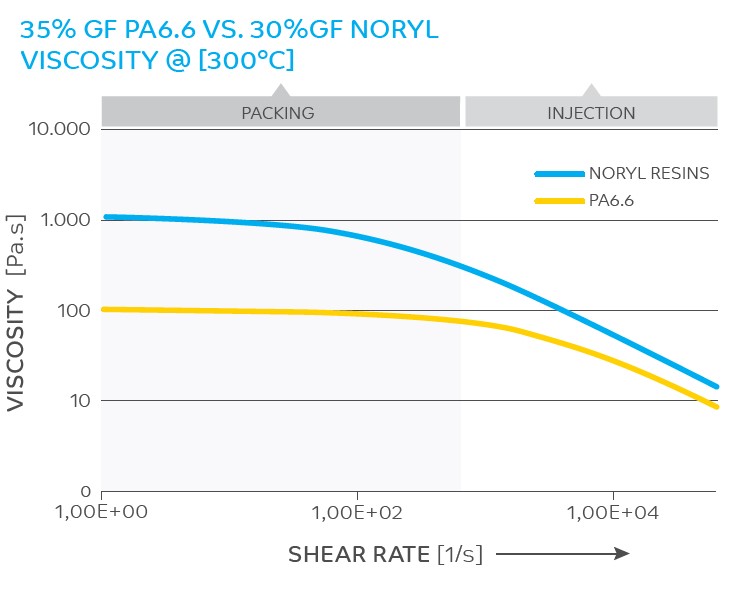

• Materials, such as NORYL resins, have higher viscosity than semi crystalline materials (e.g. PA 6.6). To compensate for it, runner and gate section need to be increased. This change will help to keep the injection pressure, material shearing and packing efficiency at similar level than with PA 6.6.

• Differences in molding shrinkage should be considered for part dimensions. Indicative mold shrinkage for 30% GF PA6,6 would be 0.2 to 0.5% for flow and 0.9 to 2% for cross flow direction, and NORYL resin would be 0.1 to 0.3% and 0.2 to 0.5%, respectively. (All measurements based on SABIC internal method that is derived from IS0294-4)

ADVANCED DESIGN AND SIMULATION SERVICES

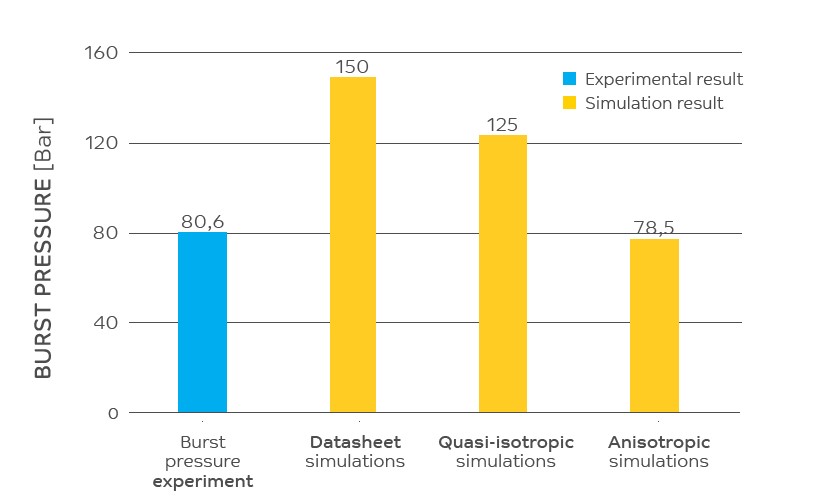

Local design modification are needed to reach equal performance with NORYL resins. Typical critical areas are weld lines, bolt connections and stress hot spots under continuous load. SABIC has developed anisotropic predictive engineering service to accurately predict part performance under various loads and temperatures.

Datasheet stiffness & strength values are best case scenario due to the favorable fiber alignment in direction to the load. Quasi-isotropic material data are closer to the reality but do not take into account the local variation of properties induced by the fiber orientation.

Anisotropic material models account for local fiber orientation and accurately predict the part performance taking into consideration temperature and stress levels. This approach can help optimizing cost and part performance.

CONTACT DETAILS:

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

Any sale by SABIC, its subsidiaries and affiliates (each a “seller”), is made exclusively under seller’s standard conditions of sale (available upon request) unless agreed otherwise in writing and signed on behalf of the seller. While the information contained herein is given in good faith, SELLER MAKES NO WARRANTY, EXPRESS OR IMPLIED, INCLUDING MER¬CHANTABILITY AND NONINFRINGEMENT OF INTELLECTUAL PROPERTY, NOR ASSUMES ANY LIABILITY, DIRECT OR INDIRECT, WITH RESPECT TO THE PERFORMANCE, SUITABILITY OR FITNESS FOR INTENDED USE OR PURPOSE OF THESE PRODUCTS IN ANY APPLICATION. Each customer must determine the suitability of seller materials for the customer’s particular use through appropriate testing and analysis. No statement by seller concerning a possible use of any product, service or design is intended, or should be construed, to grant any license under any patent or other intellectual property right. SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates, unless otherwise noted.

© 2023 Saudi Basic Industries Corporation (SABIC). All Rights Reserved.

SABIC and brands marked with TM are trademarks of SABIC or affiliates.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience