ELECTRIC VEHICLE BATTERY PACKS

LIGHTWEIGHT SPECIALTY THERMOPLASTIC MATERIALS

SAFETY, FUNCTIONALITY & PERFORMANCE FOR ELECTRIC VEHICLE BATTERY PACKS

With growing concerns of anthropogenic climate change and the imposition of stringent governmental regulations, today’s mobility industry is increasingly moving towards battery-powered electric and hybrid-electric vehicles.

To support the ‘electrification revolution,’ there exists a growing need for specialty materials to realize the potential of energy storage technologies such as Li-ion batteries.

Our teams of dedicated experts work closely with our customers to tailor unique offerings that bring high standards of safety, functionality and performance.

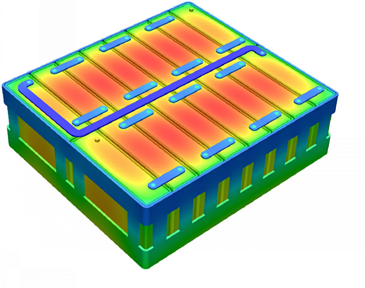

Our computer assisted engineering (CAE) team is here to assist you throughout every step of your journey, from design concepts all the way through to the completed product.

SABIC’s Specialties business offers a number of materials for use in electric vehicle (EV) battery packs that can bring:

- Weight reduction

- Fire safety

- Thermal management

- Crash safety

- Design freedom

- Enhanced processing

- Lower system cost

Our Specialties portfolio of materials can assist our customers in adressing the rigors of regulations and standards for traction motor battery packs, including UNECE R100, UL2580, GB/T 31467.3 and SAE J2929.

ENABLING THE EV REVOLUTION

SUPPORTING COMPLIANCY WITH APPROPRIATE THERMOPLASTICS

Electric vehicle safety is of unparalleled importance. In lieu of universal regulations for electric vehicle battery modules and packs, a number of stringent safety regulations and standards exist across the globe. While the robust vehicle exterior affords protection to the battery pack, the battery pack and its contents face the very real possibility of damage in the event of collisions, or even through falls during assembly and maintenance. As a result, electric vehicle battery modules and packs must undergo a series of rigorous tests including crush, drop, exposure to fire, immersion and short circuit.

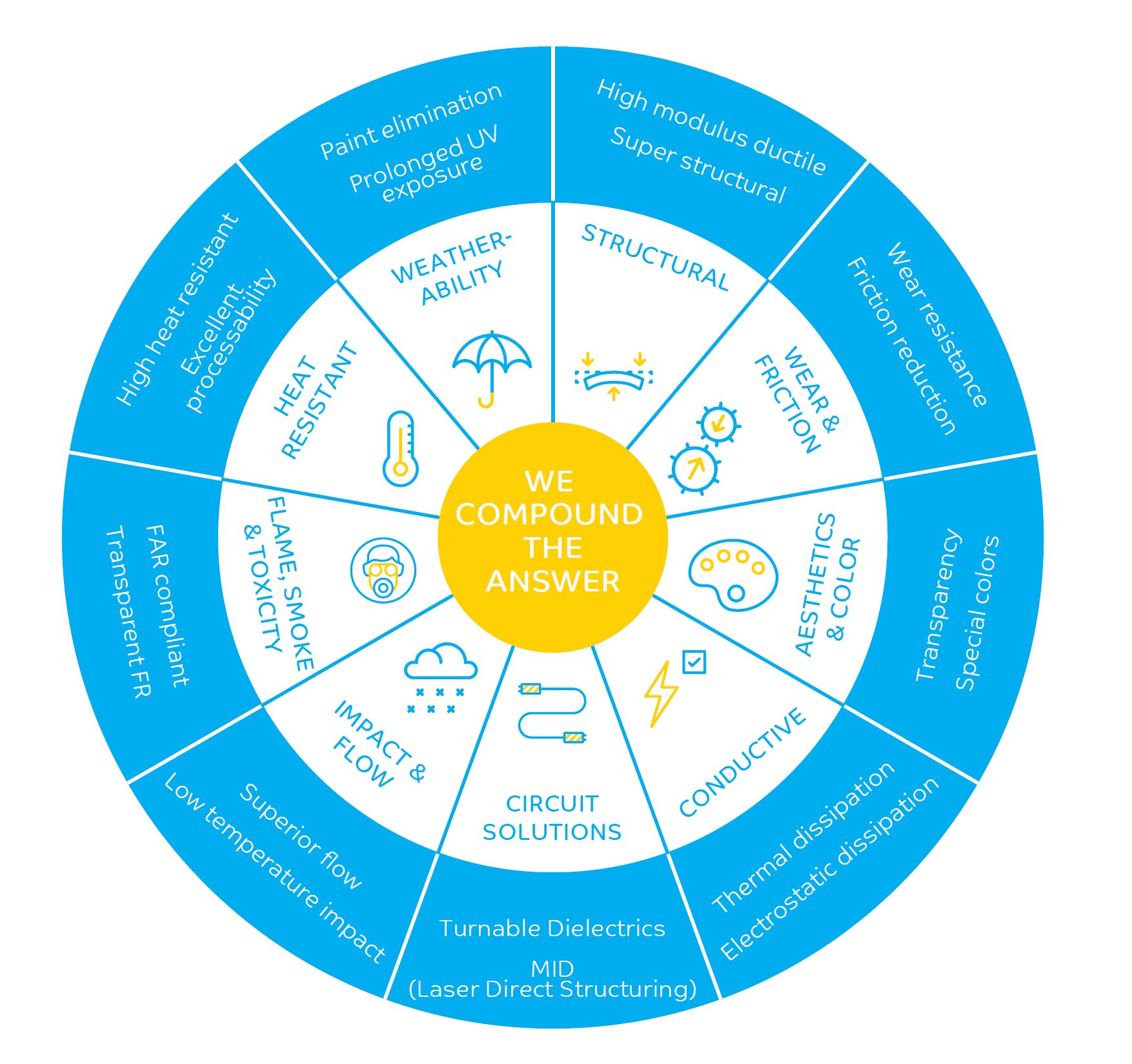

SABIC’s Specialties business offers a range of solutions with safety and functionality in mind. Our experts have a longstanding tradition of tailoring specialty solutions to meet demanding requirements, including those of electric vehicle battery packs. Whether these requirements are high impact strength and stiffness, electrical insulation or dimensional stability, or other specialty functionalities including non-chlorinated/brominated flame retardancy, electromagnetic shielding and thermal conductivity, our broad Specialties portfolio and expertise are available to help enable the global electric vehicle revolution.

COMPUTER ASSISTED ENGINEERING (CAE)

Our dedicated CAE team forms an integral part of our solutions offering and is on hand to assist our customers in every step of their developmental journey. Our customers can benefit from computer aided design and modeling to animation and simulation. At the application level, we offer structural and multiphysics analysis, as well heat and fluid flow and fluid-structure interaction. Additionally, our team is also on hand to assist you with resin processing, such as injection molding.

"Specialties’ CAE capabilities can greatly assist our customers in part and tooling design, metal replacement, thermal management and other initiatives related to electric vehicle battery pack development."

LNP™ COPOLYMERS AND COMPOUNDS

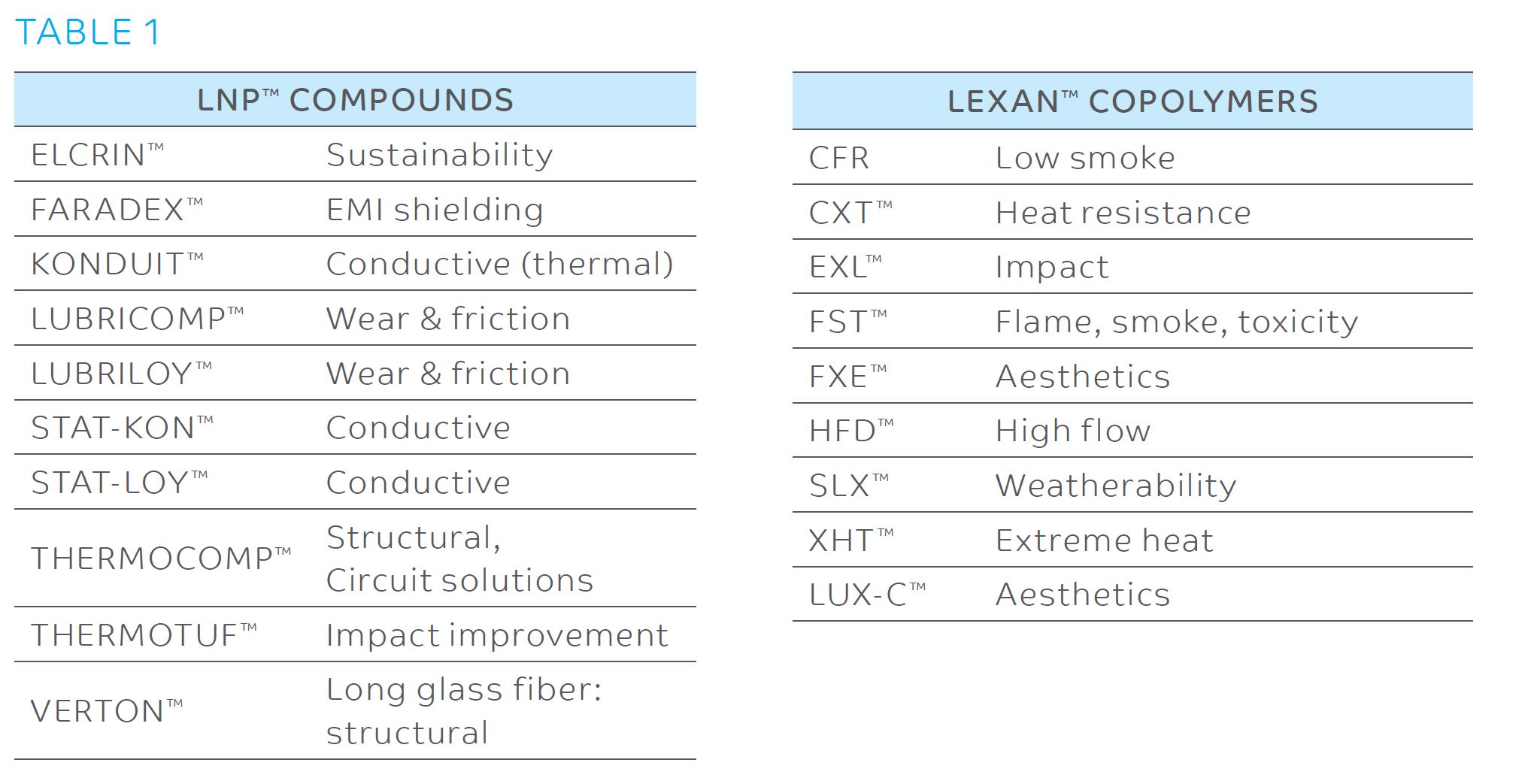

For more than 70 years, the LNP™ product line has innovated highly specialized solutions for a wide range of performance requirements, including those unique to EV batteries. LNP compounds utilize more than 30 base resins and 200 different fillers to achieve various effects. LNP copolymers are adding new dimensions to the superior properties of LEXAN™ polycarbonate.

The LNP™ portfolio features a range of product families that include LUBRICOMP™ lubricated compounds, LUBRILOY™ lubricated compounds based on alloy technology, THERMOCOMP™ reinforced compounds, THERMOTUF™ impact modified compounds, STAT-KON™ electrically conductive compounds, STAT-LOY™ anti-static compounds, VERTON™ long fiber-reinforced thermoplastics (LFRTs), FARADEX™ EMI/RFI shielding compounds, KONDUIT™ thermally conductive compounds, and COLORCOMP™ custom-colored compounds. At LNP™ we ‘compound the answer’ to your specific challenges.

The LNP™ portfolio is now also leveraging a broad palette of LEXAN™-based polycarbonate copolymers with exceptional properties for compounding. The following LEXAN™ copolymers offers unique value compared to general purpose polycarbonate and include resin portfolios with high heat resistance (XHT & CXT), low temperature ductility (EXL), superior flow and ductility (HFD), prolonged resistance to UV exposure for outdoor applications (SLX), transparent flame retardancy at thin gage (CFR), and excellent flame, smoke and toxicity properties for mass transportation (FST).

GRADE IN THE SPOTLIGHT

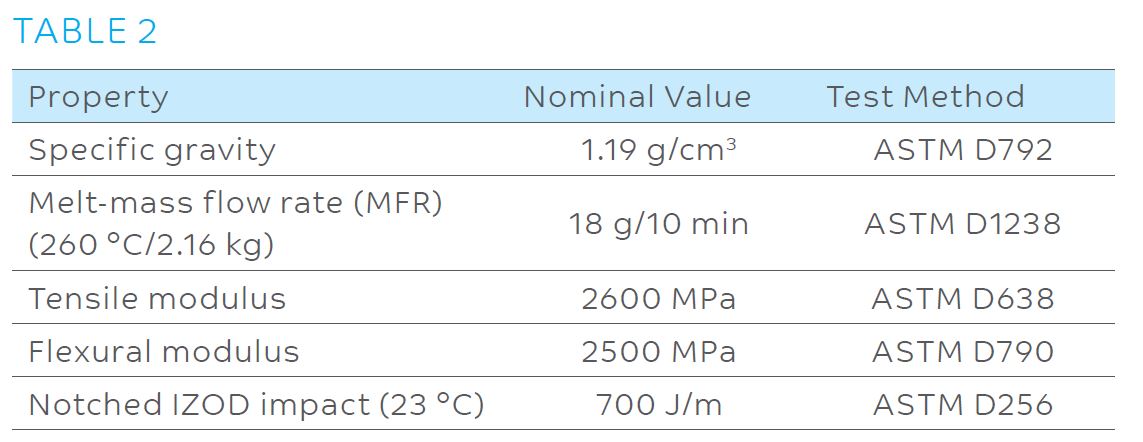

LNP™ CX7240 COMPOUND

LNP™ CX7240 compound is an injection moldable, medium flow, non-chlorinated, non-brominated flame retardant PC/ABS blend with good dimensional stability. LNP™ CX7240 compound has a UL94 V0 at 0.75mm, 5 VA at 3.0mm and 5 VB at 1.5mm flame rating and improved chemical resistance compared to standard PC/ABS blends. LNP™CX7240 compound is a good candidate for thin wall applications including cylindrical cell retainers and is an excellent candidate for battery pack module covers/housing.

NORYL™ RESIN

NORYL™ resins are built from a blend of polyphenylene ether and other polymers such as polystyrene, polyamide or polypropylene. These blends offer tunable material properties, allowing NORYL™ resins to excel in a range of different industry segments and applications. NORYL™ resins feature industry-leading low specific gravity, low moisture absorption and excellent hydrolytic stability.

The chemistry inherent to the polyphenylene ether (PPE) molecules creates mechanically strong polymers that are lightweight, high heat stable and char forming. The incorporation of various polystyrenes to PPE helps to create blends that mold and flow well in standard injection molding processes. NORYL™ resin generally exhibits excellent electrical properties that remain stable over a wide range of temperature, humidity and frequency variations. Such stability, together with a fine-tuned balance of thermal and impact properties, makes NORYL™ resin a potentially excellent candidate for a number of demanding battery pack applications.

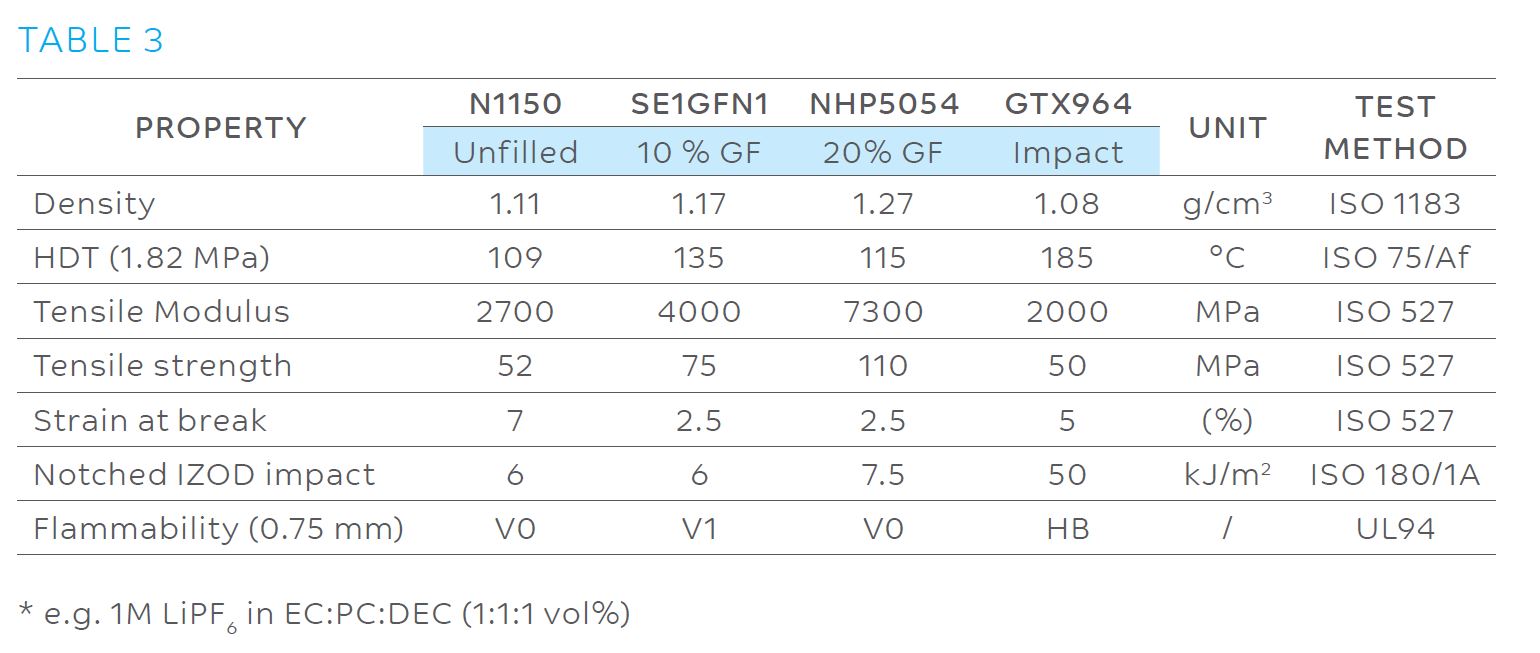

For example, select NORYL™ resin grades such as NORYL™ N1150 resin, with its high ductility, UL94 V0 flame retardancy (to 1.5 mm) and resistance to Li-ion electrolyte* are already enabling lightweight module enclosures for our customers. For larger pack enclosures where modulus is more critical, glass fiber filled NORYL™ NHP5054 resin is positioned offering greater stiffness and a UL94 V0 flame rating at 0.8 mm. With its high-energy absorption capabilities, cost effective NORYL™ GTX™ resin battery protection solution can help protect the battery during impact. The single-piece, engineered plastic honeycomb structure is e-coat capable and offers a weight reduction of up to 60% compared to multi-piece metal reinforcements.

GRADE IN THE SPOTLIGHT

NORYL™ NHP5054 RESIN

NORYL NHP5054 resin is a 20% glass reinforced blend of polyphenylene ether (PPE) and high impact polystyrene (HIPS). This injection moldable grade contains non-brominated, non-chlorinated flame retardant and carries a UL94 flame rating of V0 at 0.75 mm for thin-wall molding capability. NORYL NHP5054 resin is based on a unique copolymer technology and exhibits good dimensional stability, high heat resistance, strong electrical performance, and very low specific gravity. It is an excellent candidate for electric vehicle module and battery housings, automotive under-the-hood enclosures and components where thin-wall FR, modulus retention, and high heat resistance is required.

ULTEM™ RESIN

The ULTEM™ family of amorphous thermoplastic polyetherimide (PEI) resins offer outstanding elevated thermal resistance, high strength and stiffness, and broad chemical resistance. ULTEM™ copolymers are also available for even higher heat, chemical and elasticity needs.

ULTEM™ resins uniquely balance both mechanical properties and processability, offering design engineers exceptional flexibility and freedom. ULTEM™ resins are also inherently flame retardant and possess excellent dielectric character. ULTEM™ resins are therefore an excellent candidate for your electric vehicle battery needs where high heat resistance is required. ULTEM™ resin is available in transparent and opaque custom colors, and can be glass filled for added stiffness.

With its appreciable flow and dimensional stability, coupled with excellent resistance to Li-ion electrolyte, ULTEM™ resins such as ULTEM™ CRS5011 resin are today being used for insulation of Li-ion cell terminals. Given its excellent dielectric character, ULTEM™ resin is also an ideal candidate for bus bar insulation. For other powertrain elements, such as DC power converters, ULTEM™ UTF120 dielectric film is already enabling high temperature film capacitors. Contact us to learn more.

GRADE IN THE SPOTLIGHT

ULTEM™ CRS5011 RESIN

ULTEM CRS5011 resin is an unfilled, high temperature stable (Tg 225 °C), transparent, enhanced flow polyetherimide copolymer with enhanced chemical resistance to strong acids, bases, aromatics, and ketones. ULTEM CRS5011 resin also offers good chemical resistance to conventional Li-ion electrolytes and carries non-chlorinated/brominated UL94 V0 listing at 1.6 mm. ULTEM CRS5011 resin is an excellent candidate for EV battery pack applications where high heat, flame retardant electrical insulation is required, including cell terminal caps/covers and interlayers.

ENABLING THE 48-VOLT MILD HYBRID

ALL-PLASTIC 48 V BATTERY ENCLOSURES

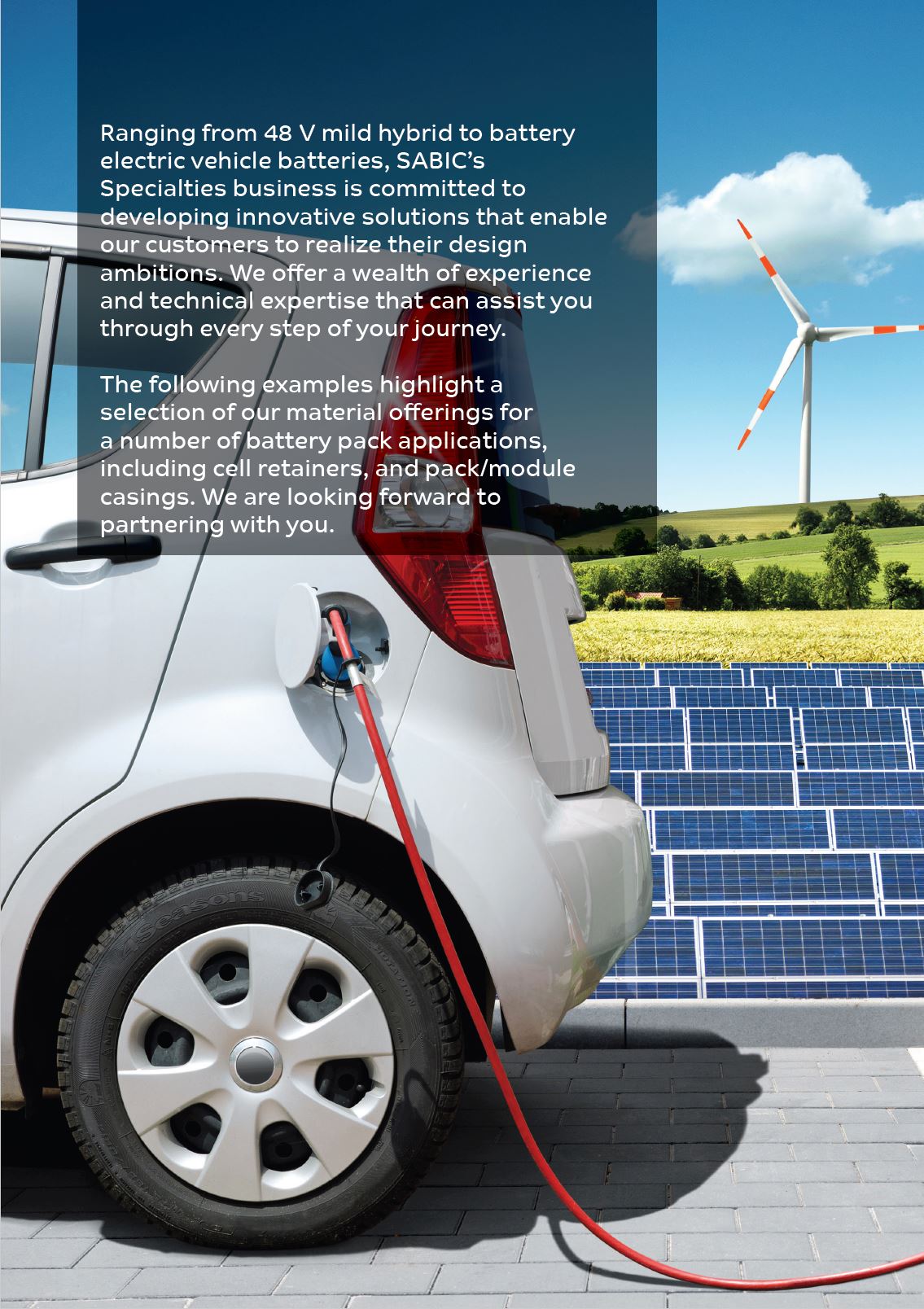

As the mobility industry faces growing pressure to increase fuel efficiency and reduce tailpipe emissions, the case for vehicle electrification grows evermore strong. Concomitantly, 48 V mild hybrid electric vehicles (MHEV), enabled by 48 V batteries, are poised to grow considerably in the coming years.

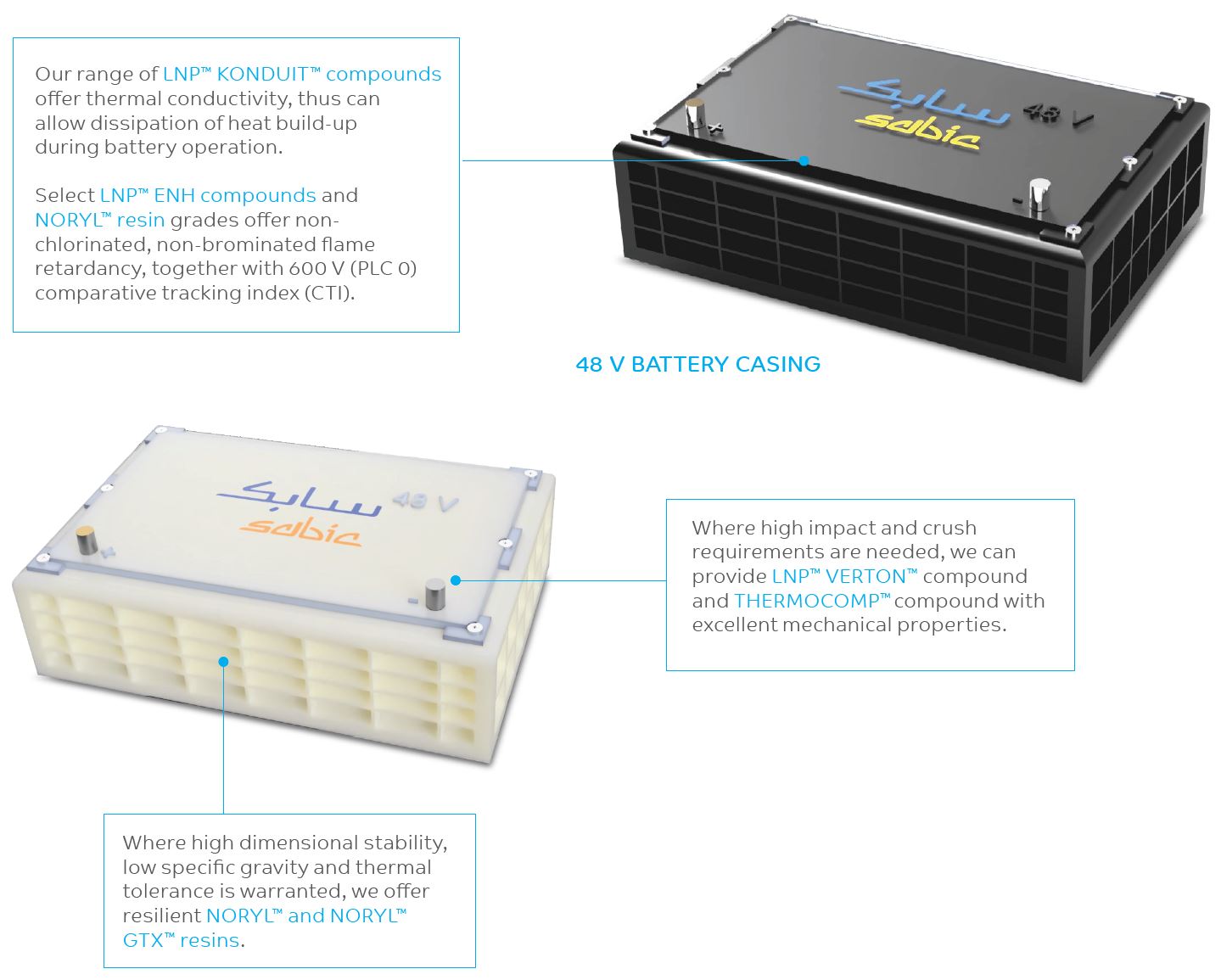

Depending on crush requirements, 48 V Li-ion batteries may be constructed using all-plastic enclosures, helping battery designers to save weight. The Specialties portfolio contains a range of mechanically resilient, lightweight materials with added functionality such as UL94 flame retardancy and thermal conductivity that can aid passive cooling.

CELL RETAINERS FOR BATTERY PACKS

INJECTION MOLDABLE, FLAME-RETARDANT SUPPORT MATERIALS

In supporting our customers’ flexibility in electric vehicle battery design, SABIC’s Specialties business offers a range of injection moldable materials for retaining cylindrical and pouch cell formats.

Working with you, our customers, we can tailor material characteristics to meet your needs such as level of flame retardancy, UV transmission or flow.

LITHIUM-ION CELL/MODULE PERIPHERALS

INJECTION MOLDABLE, FLAME-RETARDANT MATERIALS

Select Specialties injection-molding materials can be used in cell group/ module designs. Highly dimensionally stable and affording appropriate electrical insulation, our materials may be used in various spacing applications, terminal covers, housings and enclosures for prismatic cells and modules.

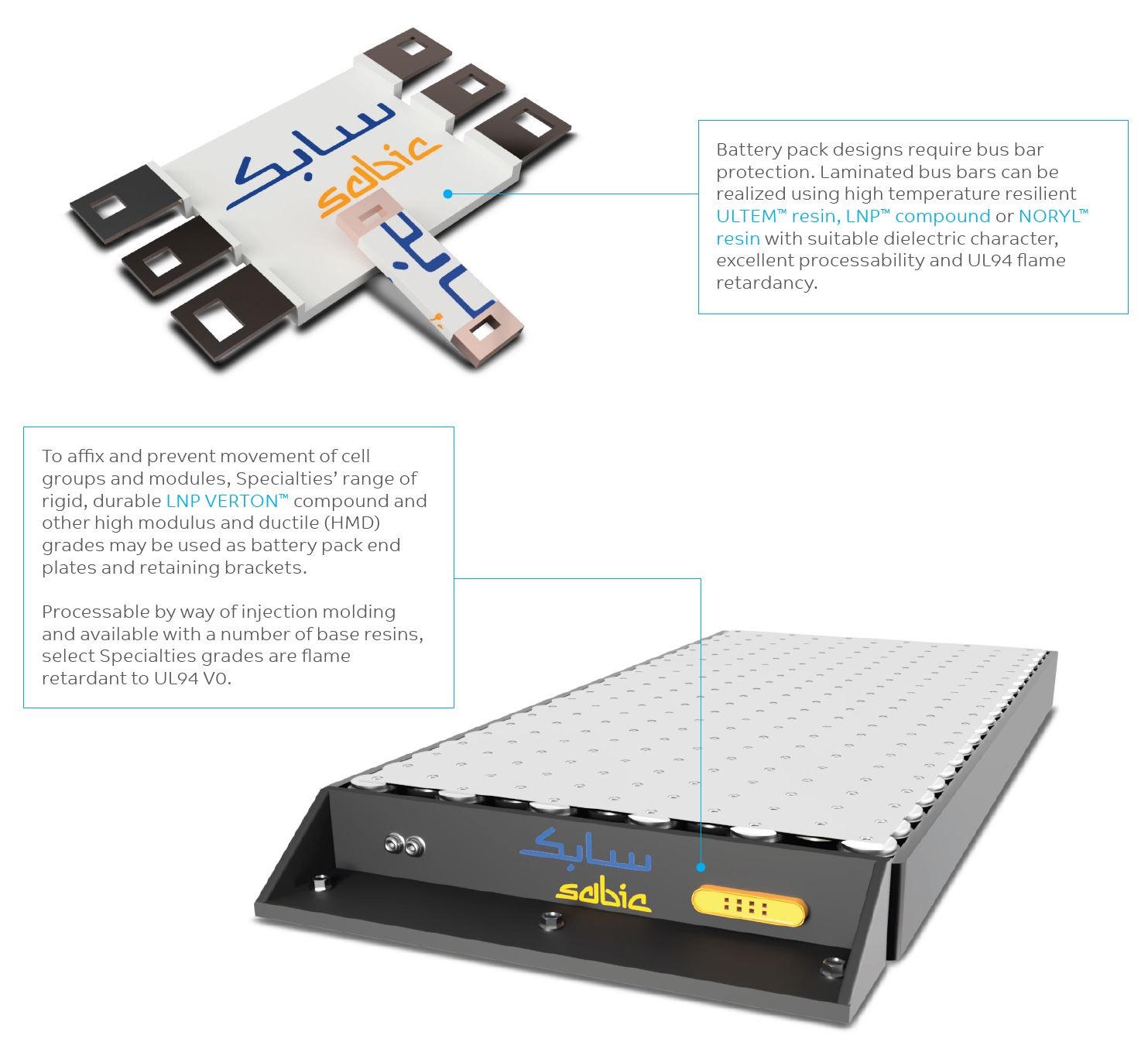

BATTERY PACK PERIPHERALS

LIGHTWEIGHT BATTERY PACK PERIPHERALS

Depending on material and design requirements, SABIC’s Specialties business can provide a number of materials for electric vehicle battery packs, including bus bar holders, covers, brackets, end plate assemblies and enclosures for battery management systems, control units, fuses and relays, etc. We are eager to help our customers reduce weight, while at all times ensuring utmost safety and compliance.

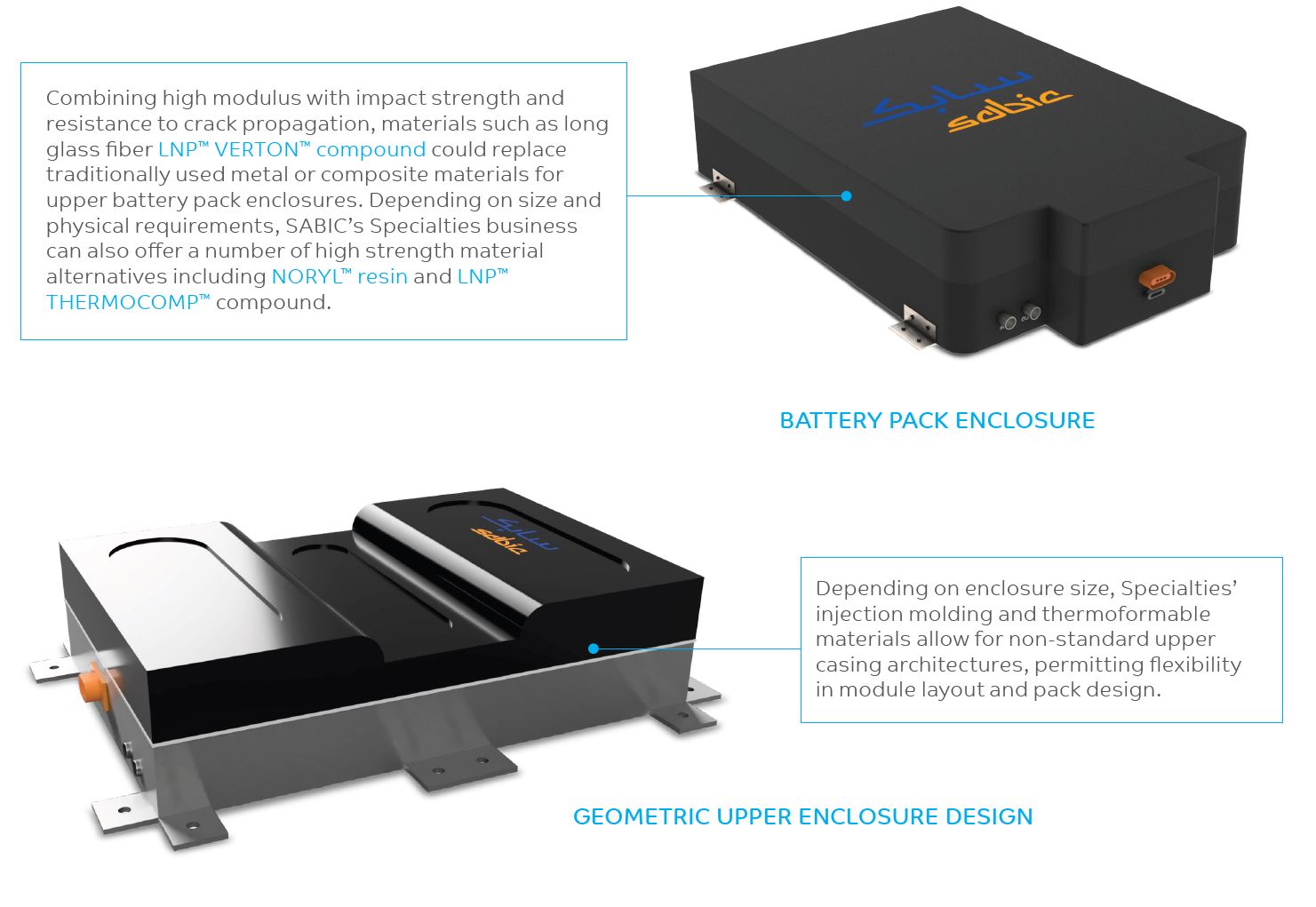

HIGH VOLTAGE BATTERY ENCLOSURES

FLAME-RETARDANT, HIGH STRENGTH UPPER ENCLOSURES

High voltage (>60 V) electric vehicle battery pack enclosures can contribute significant weight to the overall battery pack, impacting its specific energy (Wh/kg).

Certain high performance engineering thermoplastic materials can replace traditional metals, saving weight and easing the burden of cumbersome processing.

Depending on individual requirements, such as pack dimensions, Specialties’ portfolio of materials including flame-retardant

NORYL™ Resin, LNP™ VERTON™ and LNP™ THERMOCOMP™ compounds can offer the necessary qualities for electric vehicle battery upper enclosures.

Where ultimate strength is required, customers may elect to utilize UD-MAX™ tape in combination with appropriate base materials.

Specialties’ dedicated CAE teams can work directly with you can work directly with you to help tailor a range of next-generation, lightweight battery pack solutions.

BATTERY PACK PROTECTION

TOUGH, ENERGY ABSORBING IMPACT PROTECTION

Our customers tell us that safety is of the utmost importance. Common electric vehicle battery side impact countermeasures are forged from multi-piece steel stamping and extruded aluminum profiles. Such solutions are heavy at a time when weight-saving is increasingly desired.

SABIC’s Specialties business can offer singe-piece, lightweight side impact countermeasures fashioned from engineered honeycomb structures using NORYL GTX™ resin, saving our customers up to 60% in weight compared to multi-piece metal reinforcements.

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

DISCLAIMER: THE MATERIALS, PRODUCTS AND SERVICES OF SAUDI BASIC INDUSTRIES CORPORATION (SABIC) OR ITS SUBSIDIARIES OR AFFILIATES (“SELLER”) ARE SOLD SUBJECT TO SELLER’S STANDARD CONDITIONS OF SALE, WHICH ARE AVAILABLE UPON REQUEST. INFORMATION AND RECOMMENDATIONS CONTAINED IN THIS DOCUMENT ARE GIVEN IN GOOD FAITH. HOWEVER, SELLER MAKES NO EXPRESS OR IMPLIED REPRESENTATION, WARRANTY OR GUARANTEE (i) THAT ANY RESULTS DESCRIBED IN THIS DOCUMENT WILL BE OBTAINED UNDER END-USE CONDITIONS, OR (ii) AS TO THE EFFECTIVENESS OR SAFETY OF ANY DESIGN OR APPLICATION INCORPORATING SELLER’S MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS. UNLESS OTHERWISE PROVIDED IN SELLER’S STANDARD CONDITIONS OF SALE, SELLER SHALL NOT BE RESPONSIBLE FOR ANY LOSS RESULTING FROM ANY USE OF ITS MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS DESCRIBED IN THIS DOCUMENT. Each user is responsible for making its own determination as to the suitability of Seller’s materials, products, services or recommendations for the user’s particular use through appropriate end-use and other testing and analysis. Nothing in any document or oral statement shall be deemed to alter or waive any provision of Seller’s Standard Conditions of Sale or this Disclaimer, unless it is specifically agreed to in a writing signed by Seller. Statements by Seller concerning a possible use of any material, product, service or design do not, are not intended to, and should not be construed to grant any license under any patent or other intellectual property right of Seller or as a recommendation for the use of any material, product, service or design in a manner that infringes any patent or other intellectual property right.

SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates.

© 2023 Copyright SABIC. All rights reserved

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience