STATIONARY GRID-SCALE ENERGY STORAGE BATTERIES

SPECIALTY THERMOPLASTICS HELP ENERGY STORAGE BATTERIES DELIVER RELIABLE PERFORMANCE AND EFFICIENCY FOR POWER GRIDS

Designers require materials that can retain excellent electrical and

mechanical properties in a demanding electrolyte environment.

Batteries used for stationary, utility-scale energy storage are a critical component of power grids, especially systems that use renewable energy sources such as solar and wind. Many energy storage systems use lithium-ion and flow batteries. Because these batteries incorporate electrolytes containing harsh or corrosive chemicals, their components must provide robust resistance.

Specialty materials from SABIC can withstand degradation from exposure to corrosive electrolytes, helping to ensure battery reliability, efficiency and long service life. LNP™ STAT-KON™ compounds and NORYL™ resins provide excellent chemical resistance and other desirable properties, making them good candidates for energy storage battery components. Potential applications include conductive electrodes, terminal ends, housings and fluid management components such pumps, valves, and tanks for electrolyte handling. In addition, SABIC can optimize material properties further to meet specific application requirements.

Compounding Expertise You Can Rely On

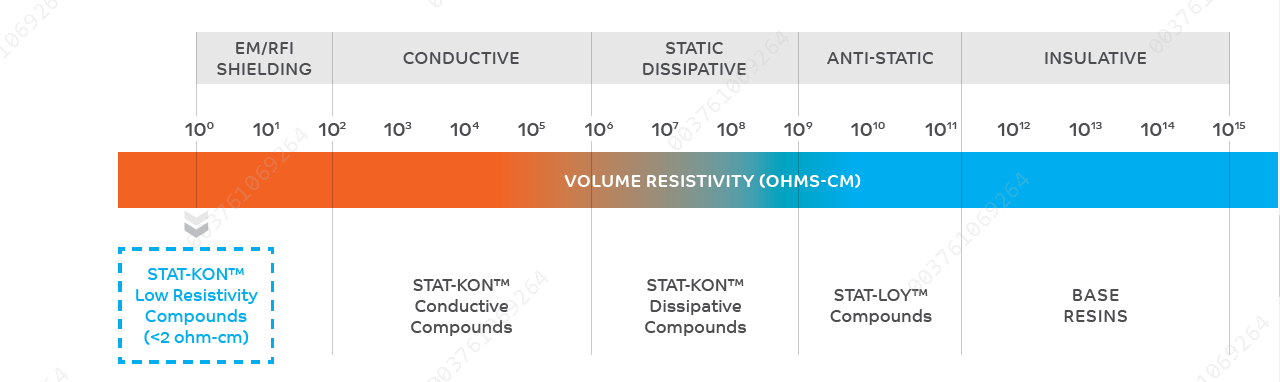

LNP compounds are formulated by melt blending different base resins with reinforcements and additives to deliver targeted properties such as conductivity, thermal management and EMI/RFI shielding.

SABIC introduced the first LNP conductive compounds to market in 1974 and has steadily expanded this conductive portfolio since then. The latest addition to the LNP compound family? Low resistivity conductive compounds.

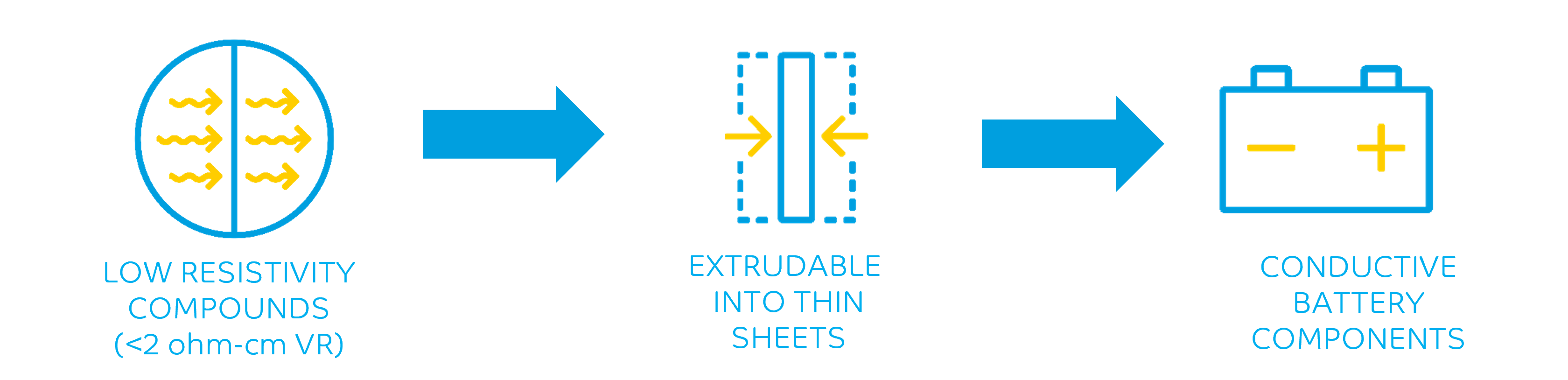

LOW RESISTIVITY LNP™ STAT-KON™ COMPOUNDS IN CONDUCTIVE COMPONENTS

Low volume resistivity (<2 ohm-cm) LNP STAT-KON compounds are well suited for conductive electrodes and terminal ends in energy storage batteries. Besides excellent chemical resistance to help withstand corrosive electrolytes, they offer the following:

• Good ductility and mechanical performance

• Melt processability into thin sheets using conventional extrusion equipment

• Streamlined processing vs. metal through elimination of secondary operations

• Lighter weight than metal, contributing to ease of battery handling

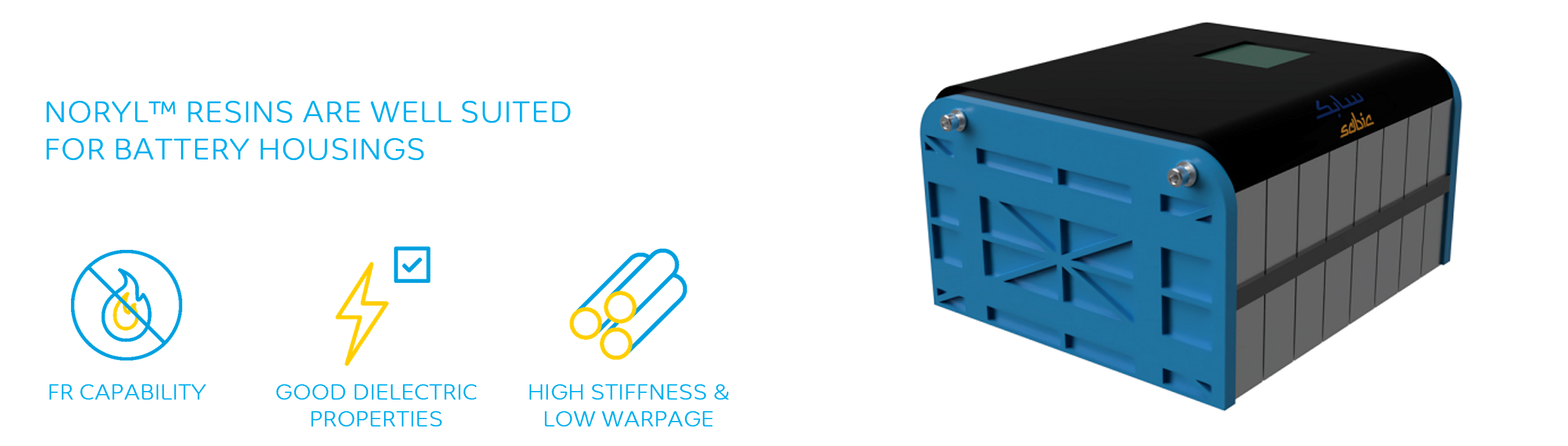

NORYL™ RESINS IN BATTERY COMPONENTS

NORYL resins are formulated by blending PPE with PS, nylon, PP or TPE. The excellent chemical resistance of these materials combined with the below properties make NORYL resins well suited for use in battery housings as well as fluid management components such as pumps, valves, and tanks for electrolyte handling.

Thanks to its high modulus and inherent stiffness properties, unreinforced NORYL resin can potentially replace materials that require glass fiber reinforcement to achieve a high level of stiffness. Elimination of glass fibers can improve isotropic dimensional stability, facilitate molding of complex parts and make it easier to join parts using heat staking and ultrasonic and hot plate welding.

Let SABIC help you with potential materials for your energy storage battery needs.

Reach out to us today to discuss how we can support your product development team with expertise in materials, design, application development, processing and testing.

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

Any sale by SABIC, its subsidiaries and affiliates (each a “seller”), is made exclusively under seller’s standard conditions of sale (available upon request) unless agreed otherwise in writing and signed on behalf of the seller. While the information contained herein is given in good faith, SELLER MAKES NO WARRANTY, EXPRESS OR IMPLIED, INCLUDING MERCHANTABILITY AND NONINFRINGEMENT OF INTELLECTUAL PROPERTY, NOR ASSUMES ANY LIABILITY, DIRECT OR INDIRECT, WITH RESPECT TO THE PERFORMANCE, SUITABILITY OR FITNESS FOR INTENDED USE OR PURPOSE OF THESE PRODUCTS IN ANY APPLICATION. Each customer must determine the suitability of seller materials for the customer’s particular use through appropriate testing and analysis. No statement by seller concerning a possible use of any product, service or design is intended, or should be construed, to grant any license under any patent or other intellectual property right. SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates, unless otherwise noted.

© 2024 Saudi Basic Industries Corporation (SABIC). All Rights Reserved.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience