EV THERMAL MANAGEMENT APPLICATIONS WITH SABIC’S ULTEM™ RESIN

RELIABLE PRECISION & STRENGTH WITH CHEMICAL RESISTANCE

From thermal runaway mitigation to the ever-growing number of power electronics, designing an efficient thermal management systems (TMS) plays a critical role within electric vehicles to improve performance and reliability across temperature range while ensuring passenger comfort.

The main trends driving further development in TMS are:

• Higher voltage architectures

• Increased electronic components

• Fast / Super Fast charging

• Thermal runaway mitigation

Material selection is critical for development of innovative TMS architectures to withstand direct exposure to refrigerants and coolant fluids while providing reliability benefits in the overall design of electric vehicles and charging infrastructure.

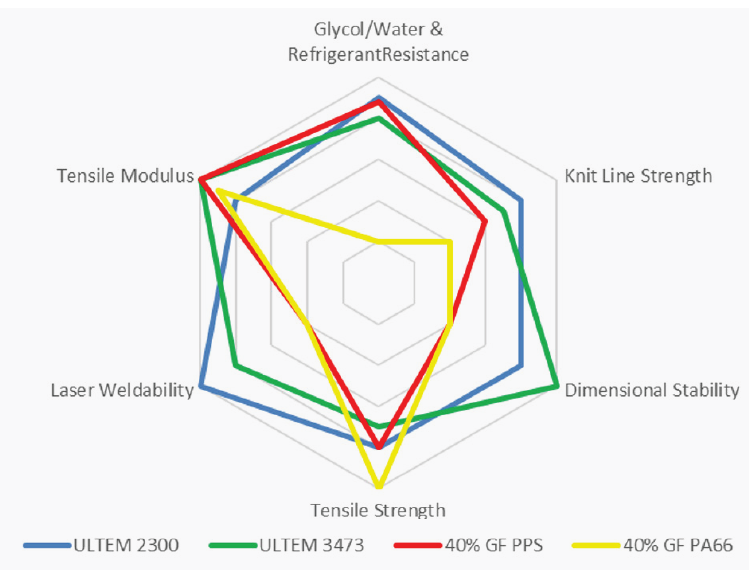

SABIC’s ULTEM™ resin (PEI) meets chemical resistance exposure testing similar to PPS (GF 40%) and PA66 (GF 40%) while offering the following benefits:

• Dimensional stability (-40c to 130c)

• Low CTE for precision tolerancing

• Laser weldability for ease of assembly

• Light weighting

• Design freedom for integrating features & part consolidation

• Inherent heat resistance

POTENTIAL APPLICATIONS MAY INCLUDE:

• On-board chargers

• Power inverters

• DC/DC converters

• Fast-charging handles

• Hoses

• Sensors and lenses

• Connectors

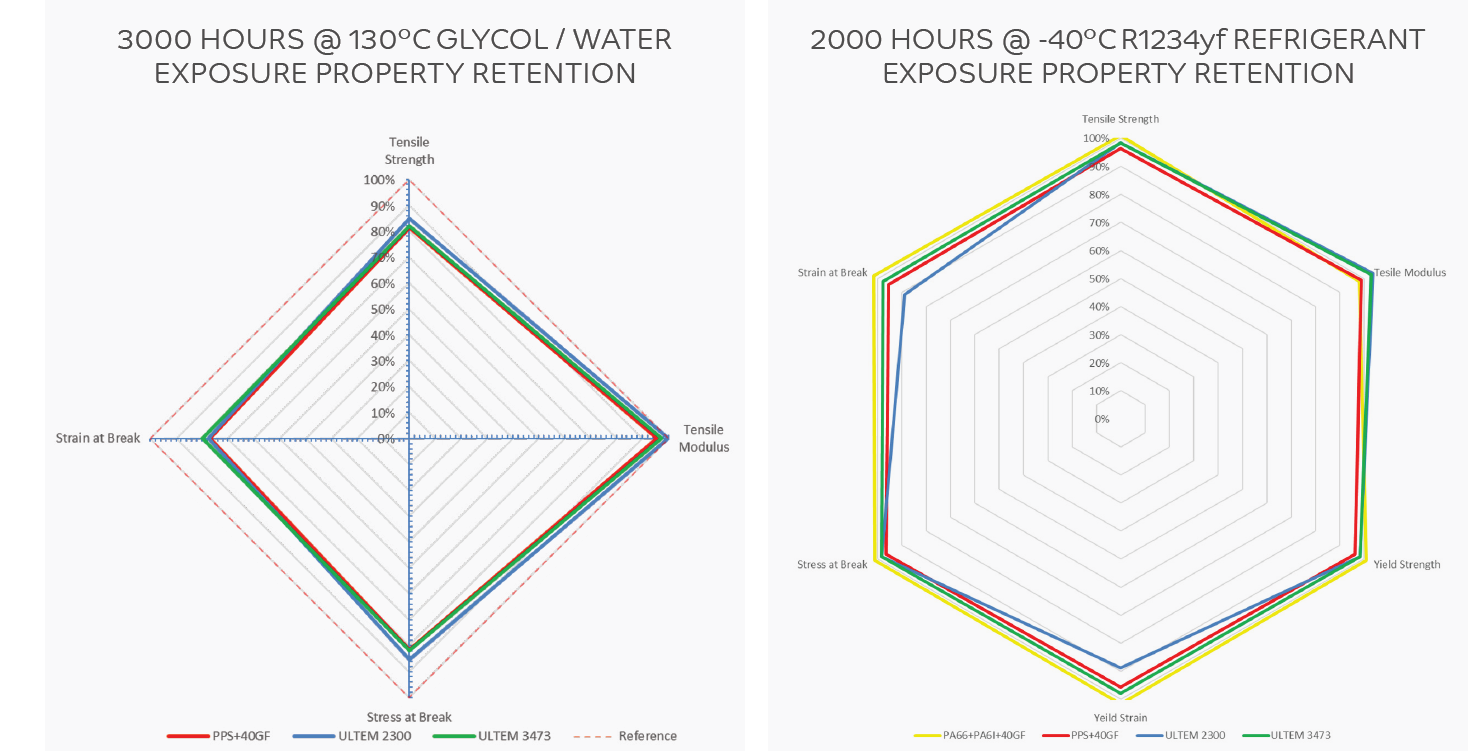

ULTEM™ RESIN PROPERTY RETENTION COMPARISON

PA66 (GF 40%) did not withstand 3000 hours

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

DISCLAIMER: THE MATERIALS, PRODUCTS AND SERVICES OF SAUDI BASIC INDUSTRIES CORPORATION (SABIC) OR ITS SUBSIDIARIES OR AFFILIATE S (“SELLER”) ARE SOLD SUBJECT TO SELLER’S STANDARD CONDITIONS OF SALE, WHICH ARE AVAILABLE UPON REQUEST. INFORMATION AND RECOMMENDATIONS CONTAINED IN THIS DOCUMENT ARE GIVEN IN GOOD FAITH. HOWEVER, SELLER MAKES NO EXPRESS OR IMPLIED REPRESENTATION, WARRANTY OR GUARANTEE ( i ) THAT ANY RESULTS DESCRIBED IN THIS DOCUMENT WILL BE OBTAINED UNDER END USE CONDITIONS, OR (ii) AS TO THE EFFECTIVENESS OR SAFETY OF ANY DESIGN OR APPLICATION INCORPORATING SELLER’S MATERIALS, PRODUCTS , SERVICES OR RECOMMENDATIONS. UNLESS OTHERWISE PROVIDED IN SELLER’S STANDARD CONDITIONS OF SALE, SELLER SHALL NOT BE RESPONSIBLE FOR ANY LOSS RESULTING FROM ANY USE OF ITS MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS DESCRIBED IN THIS DOCUMENT. Each user is responsible for making its own determination as to the suitability of Seller’s materials, products, serv ices or recommendations for the user’s particular use through appropriate end use and other testing and analysis. Nothing in any document or oral statement shall be deemed to alter or waive any provision of Seller’s Standard Conditions of Sale or this Disclaimer, unless it is specifically agreed to in a writing signed by Seller. Statements by Seller concerning a possible use of any material, product, service or design do not, are not intended to, and should not be construed to grant any license under any patent or other intellectual property right of Seller or as a recommendation for the use of any material, product, service or design in a manner that infringes any patent or other intellectual property right.

SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates, unless otherwise noted.

©2023 Saudi Basic Industries Corporation (SABIC). All Rights Reserved.

Any brands, products or services of other companies referenced in this document are the trademarks, service marks and/or trade names of their respective holders.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience