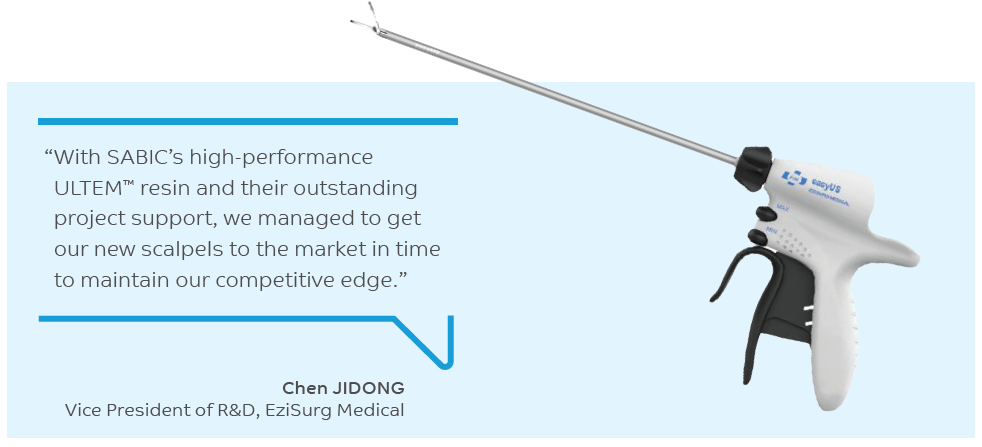

EZISURG MEDICAL RELIES ON SABIC’S ULTEM™ RESIN FOR HIGH-PERFORMANCE PREMIUM ULTRASONIC SCALPEL SHEARS

THE CUSTOMER

EziSurg Medical Co., Ltd. (ESM) specializes in the development and commercialization of high-end, minimally invasive surgical instruments. The Shanghai-based company, a China market leader in medical scalpel systems, was looking for a material solution to help maintain and build on their competitive strength in these demanding medical devices, both locally and abroad. Their goal was to find a polymer capable of outperforming incumbent materials, including polysulfones, in the next generation of their fast-cutting easyUS® premium ultrasonic scalpel shears.

THE CHALLENGE

Basic material requirements included long-term thermal and mechanical stability, as well as ease of processing. In addition to the many clinical performance characteristics, it was important that the new solution supported a safe and clean surgical environment. Lastly, design flexibility was desired to help achieve an optimal balance of flexural strength and toughness to address the torque force performance requirements needed during device assembly and surgery.

THE SOLUTION

Leveraging comprehensive local and technical support from SABIC in material selection, including part and mold design, ESM succeeded in developing a new range of scalpels with components molded in ULTEM™ resin, a high-performance polyetherimide (PEI) material that met the manufacturer’s critical expectations. The smooth collaboration between the two teams helped accelerate the time to market for the redesigned instruments. SABIC also supplied significant data support, which included key material performance characteristics for this application, and assisted the customer in optimizing the final processing parameters.

ULTEM™ RESIN PROVIDES

Outstanding wear and abrasion resistance to minimize the generation of small particles from the frequent assembly and disassembly of the scalpel devices, which could potentially cause contamination.

• Excellent hydrolytic stability and chemical resistance for flexible sterilization

(gamma, EtO, plasma, autoclave) and ease of cleaning with medical disinfectants.

• Long-term heat resistance (RTI >170°C) for withstanding multiple autoclave cycles.

• Outstanding dimensional stability, as well as an optimum balance of mechanical strength and ductility, which have been instrumental in enhancing reliability and extending the usable life of the surgical instruments.

• High flow capability for greater design freedom and cost-efficient injection molding of complex components.

In addition, ULTEM resins from SABIC comply with certain medical and environmental standards and regulations, including FDA, USP Class VI, ISO 10993, WEEE and RoHS.

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

DISCLAIMER: THE MATERIALS, PRODUCTS AND SERVICES OF SAUDI BASIC INDUSTRIES CORPORATION (SABIC) OR ITS SUBSIDIARIES OR AFFILIATES ("SELLER") ARE SOLD SUBJECT TO SELLER'S STANDARD CONDITIONS OF SALE, WHICH ARE AVAILABLE UPON REQUEST. INFORMATION AND RECOMMENDATIONS CONTAINED IN THIS DOCUMENT ARE GIVEN IN GOOD FAITH. HOWEVER, SELLER MAKES NO EXPRESS OR IMPLIED REPRESENTATION, WARRANTY OR GUARANTEE (i) THAT ANY RESULTS DESCRIBED IN THIS DOCUMENT WILL BE OBTAINED UNDER END-USE CONDITIONS, OR (ii) AS TO THE EFFECTIVENESS OR SAFETY OF ANY DESIGN OR APPLICATION INCORPORATING SELLER'S MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS.UNLESS OTHERWISE PROVIDED IN SELLER'S STANDARD CONDITIONS OF SALE, SELLER, SHALL NOT BE RESPONSIBLE FOR ANY LOSS RESULTING FROM ANY USE OF ITS MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS DESCRIBED IN THIS DOCUMENT. Each user is responsible for making its own determination as to the suitability of Seller's materials, products, services or recommendations for the user's particular use through appropriate end-use and other testing and analysis. Nothing in any document or oral statement shall be deemed to alter or waive any provision of Seller's Standard Conditions of Sale or this Disclaimer, unless it is specifically agreed to in a writing signed by seller. Statements by Seller concerning a possible use of any material, product, service or design do not, are not intended to, and should not be construed to grant any license under any patent or other intellectual property right of Seller or as a recommendation for the use of any material, product, service or design in a manner that infringes any patent or other intellectual property right.

SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates, unless otherwise noted © 2023 Saudi Basic Industries Corporation (SABIC). All Rights Reserved. Any brands, products or services of other companies referenced in this document are the trademarks, service marks and/or trade names of their respective holders.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience