LNP™ EXL COPOLYMER RESINS FOR HEALTHCARE

LNP™ EXL COPOLYMER RESINS HEALTHCARE PORTFOLIO

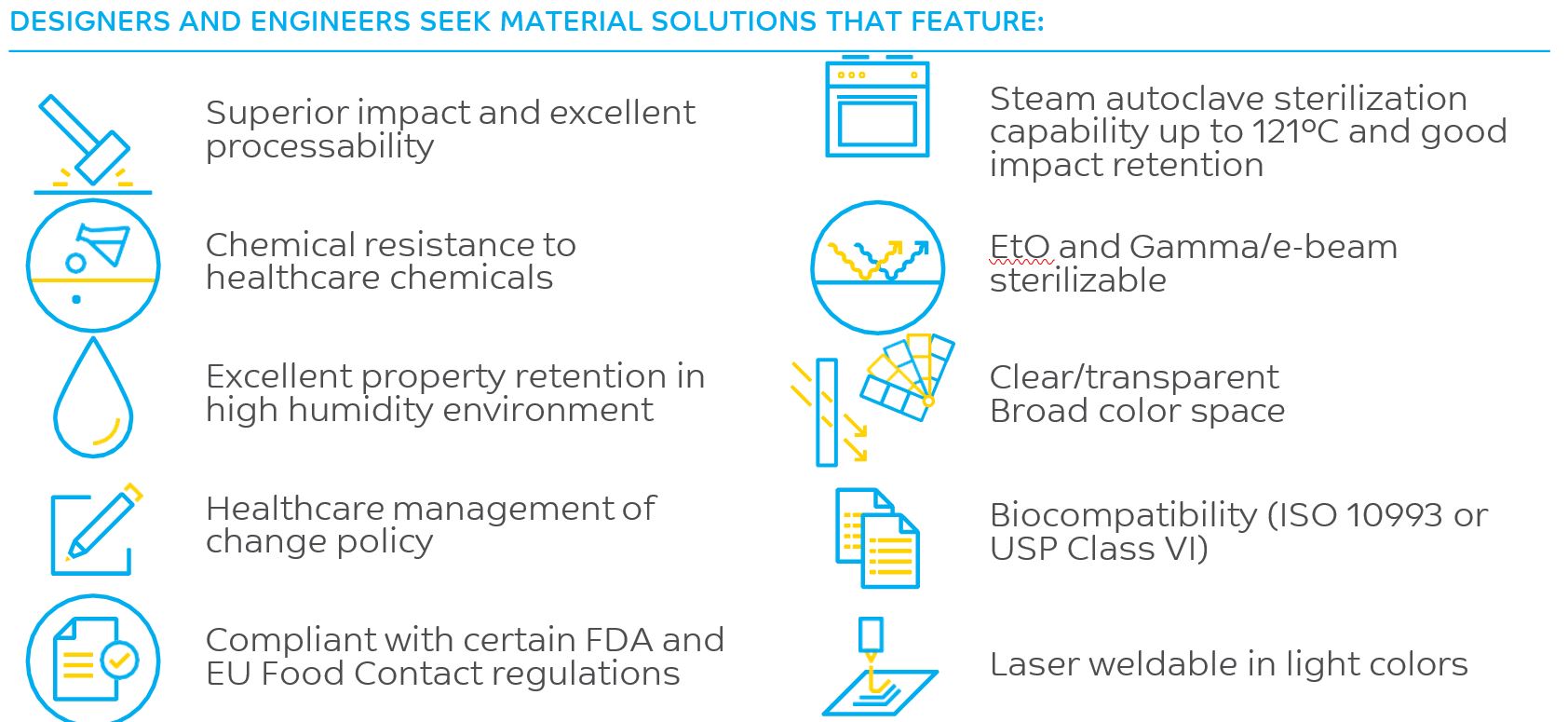

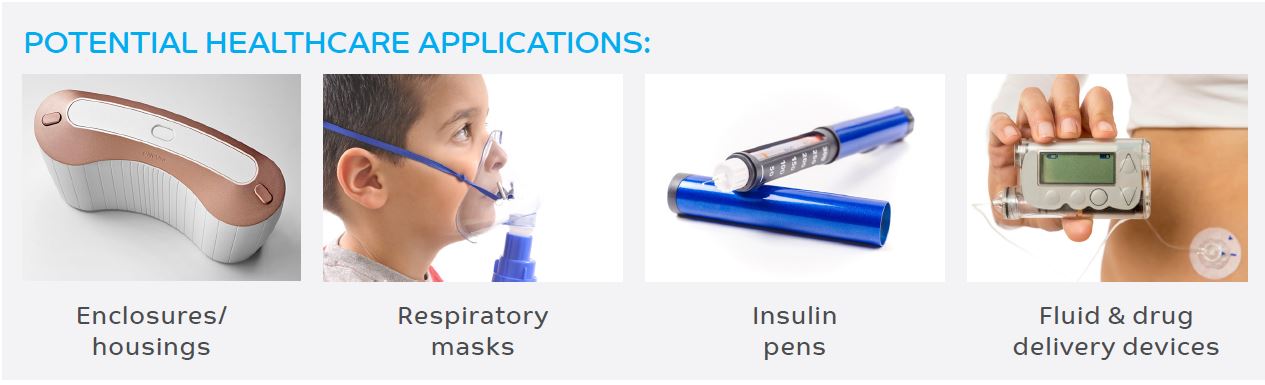

Applications in the healthcare industry have unique and demanding requirements. Thermoplastic material selection for medical

devices and equipment housings will continue to be very important to help keep vital equipment in service for longer periods of time, reduce system costs, and support improved patient safety.

OEMs can collaborate with material suppliers early within the design process to identify the appropriate solutions to meet performance requirements.

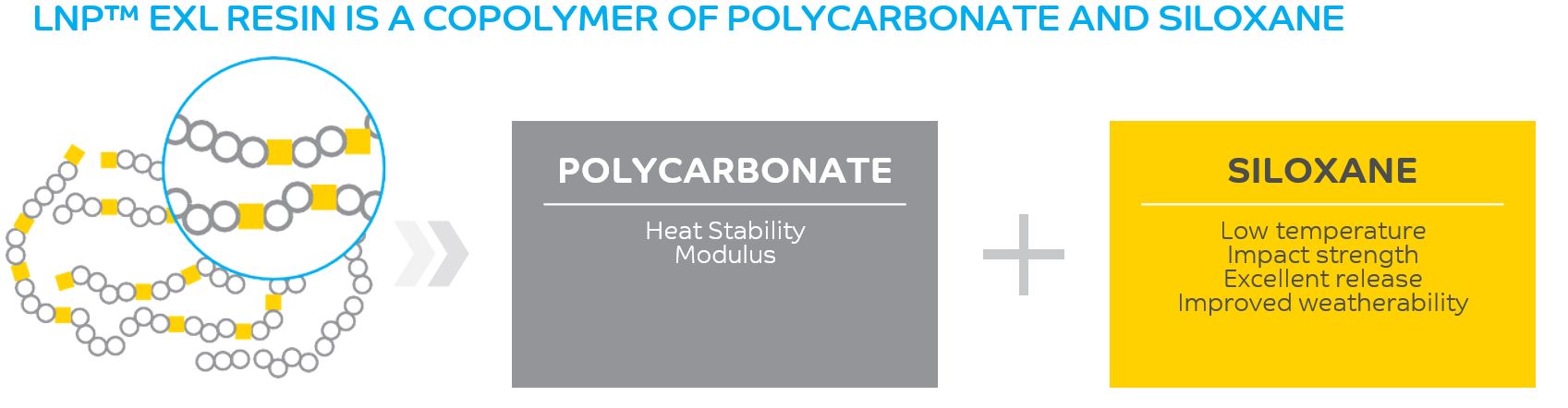

The EXL copolymer structure combines the best of PC and siloxane properties, resulting in a significant improvement vs. standard PC and PC blends. The siloxane forms a chemical link in the PC backbone to provide outstanding low temperature impact performance. Since silicone is relatively unaffected by heat or humidity under typical aging conditions, the materials retain their properties longer than standard PC.

The improved toughness of EXL copolymer resin addresses cracking or ductility limitations that can occur with standard PC or PC/ABS blends. EXL resin can offer enhanced performance when using snap fit or metal insert designs and allow for lower draft angles and lower levels of molded-in stresses, as compared to standard PC.

POTENTIAL BENEFITS OF LNP™ EXL COPOLYMER RESINS:

- Impact: Outstanding balance of ductility (up to -30°C) and viscosity

- Weatherability: Excellent retention of mechanical properties in outdoor exposure

- Aging: Improved retention of properties vs. other PC resins

- Flame Retardance: FR grades can be used in many applications that required compliance with certain sustainability or environmental standards

- Knit line Strength: A significant improvement over PC/ABS materials

- Chemical Resistance: Improved chemical resistance to some chemicals compared to standard PC resins

PROCESSING EXL RESINS

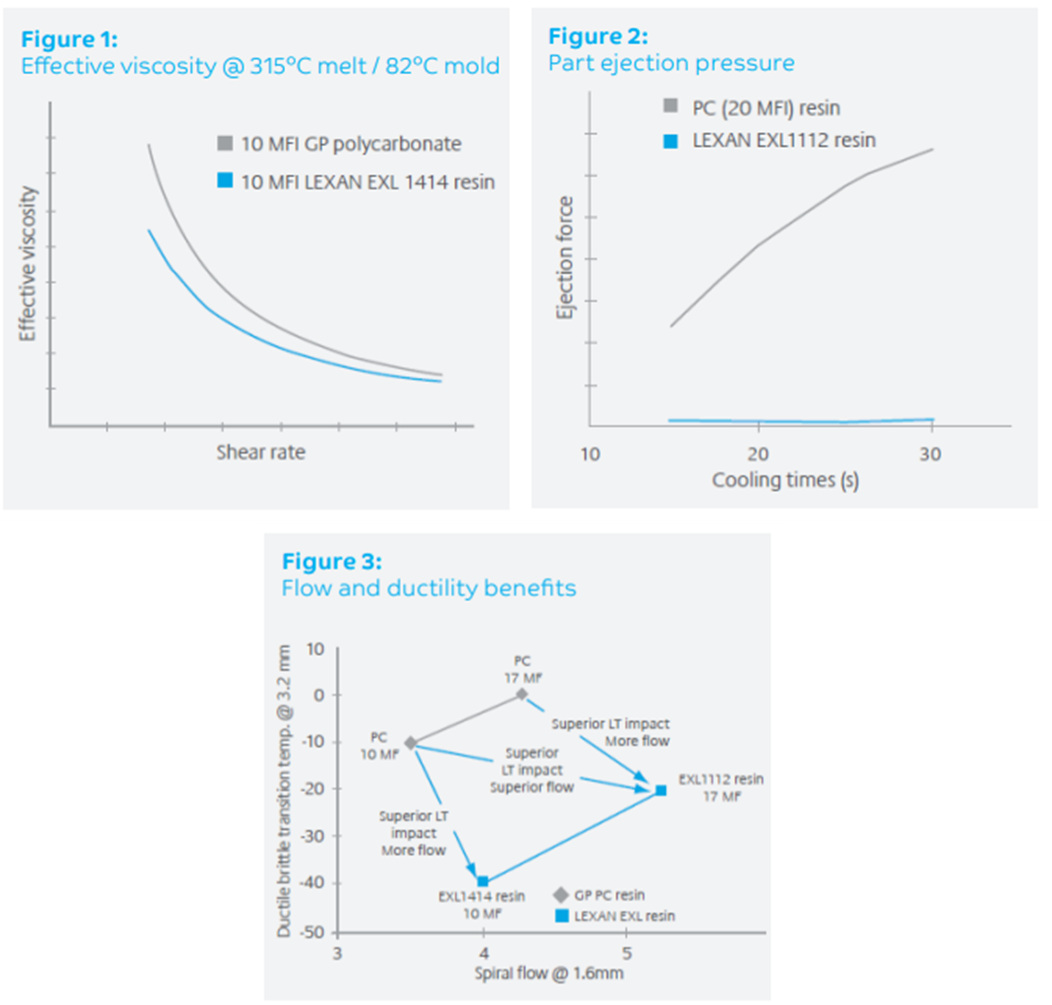

Extensive studies at SABIC’s Polymer Processing Development Center (PPDC) have found that, compared to a standard PC resin of the same melt flow, EXL resin exhibits lower effective viscosity at comparable shear rates that can contribute to a reduction in injection pressure (see Figure 1).

Since the silicone component of the copolymer is bound to the resin, there is little tool deposit during molding. Additionally, the use of specific release additives, which can result in tool deposit, can be eliminated. Due to inherent release properties, part ejection pressures (see Figure 2) are lower. Depending on tool design, EXL resin compared to PC resin, may provide reduced cycle times.

EXL resins exhibit versatility in flow and impact performance. Spiral flow studies have confirmed a significant improvement in flow length. When compared to standard PC resins in the range of 10 to 17 MFR, EXL resins provide multiple opportunities to offer increased toughness and flow (see Figure 3).

POTENTIAL PROCESSING BENEFITS USING LNP™ EXL COPOLYMER RESINS

(depending on tool design):

· Lower injection pressures

· Lower ejection pressures

· Higher flow

· Improved ductility/toughness

· Shorter production cycle time

· Lower draft angles

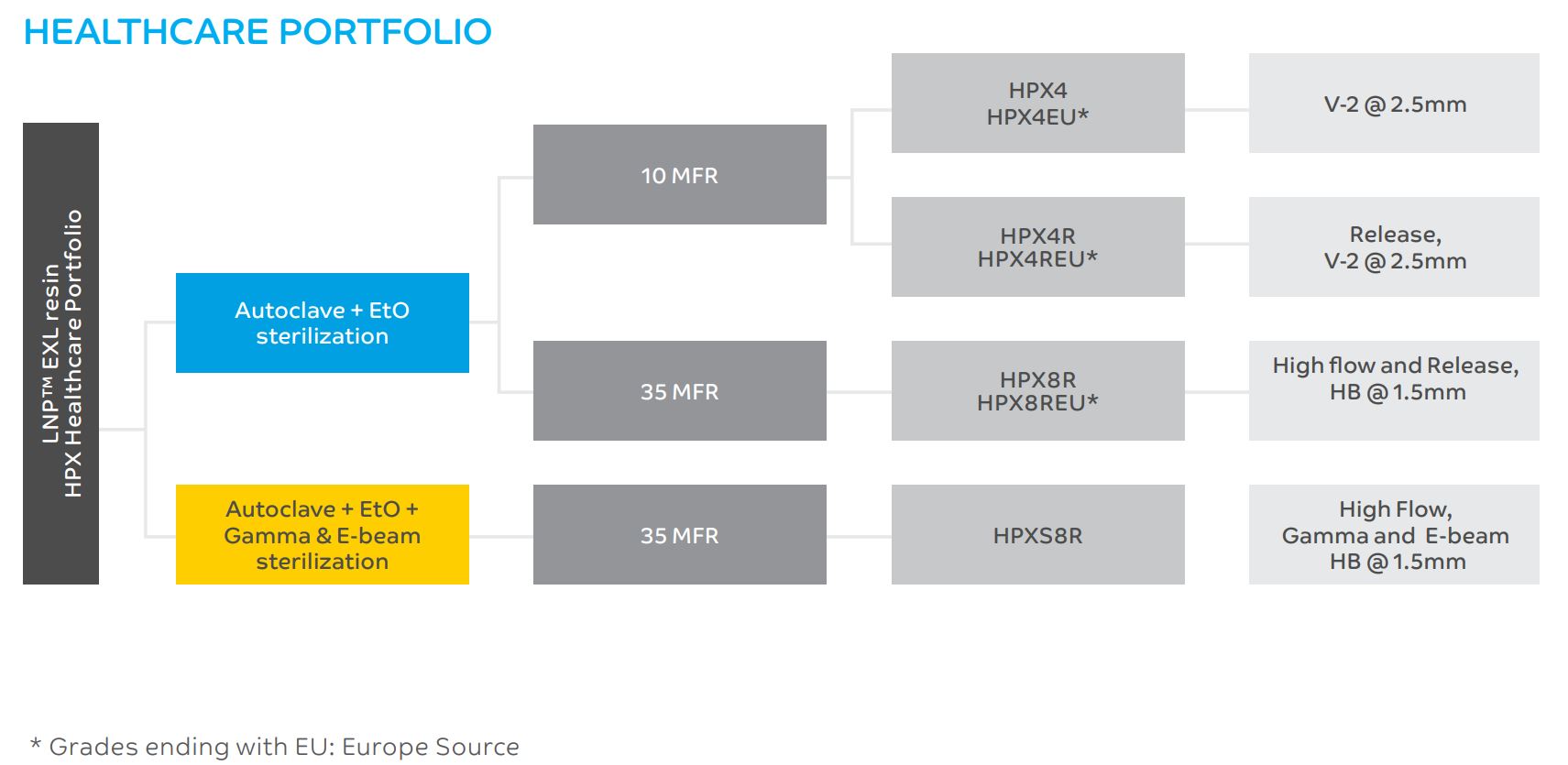

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

DISCLAIMER: THE MATERIALS, PRODUCTS AND SERVICES OF SAUDI BASIC INDUSTRIES CORPORATION (SABIC) OR ITS SUBSIDIARIES OR AFFILIATES (“SELLER”) ARE SOLD SUBJECT TO SELLER’S STANDARD CONDITIONS OF SALE, WHICH ARE AVAILABLE UPON REQUEST. INFORMATION AND RECOMMENDATIONS CONTAINED IN THIS DOCUMENT ARE GIVEN IN GOOD FAITH. HOWEVER, SELLER MAKES NO EXPRESS OR IMPLIED REPRESENTATION, WARRANTY OR GUARANTEE

(i) THAT ANY RESULTS DESCRIBED IN THIS DOCUMENT WILL BE OBTAINED UNDER END-USE CONDITIONS, OR (ii) AS TO THE EFFECTIVENESS OR SAFETY OF ANY DESIGN OR APPLICATION INCORPORATING SELLER’S MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS. UNLESS OTHERWISE PROVIDED IN SELLER’S STANDARD CONDITIONS OF SALE, SELLER SHALL NOT BE RESPONSIBLE FOR ANY LOSS RESULTING FROM ANY USE OF ITS MATERIALS, PRODUCTS, SERVICES OR

RECOMMENDATIONS DESCRIBED IN THIS DOCUMENT. Each user is responsible for making its own determination as to the suitability of Seller’s materials, products, services or recommendations for the user’s particular use through appropriate end-use and other testing and analysis. Nothing in any document or oral statement shall be deemed to alter or waive any provision of Seller’s Standard Conditions of Sale or this Disclaimer, unless it is specifically agreed to in a writing signed by Seller. Statements by Seller concerning a possible use of any material, product, service or design do not, are not intended to, and should not be construed to grant any `license under any patent or other intellectual property right of Seller or as

a recommendation for the use of any material, product, service or design in a manner that infringes any patent or other intellectual property right.

SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates, unless otherwise noted.

© 2021 Saudi Basic Industries Corporation (SABIC). All Rights Reserved. Any brands, products or services of other companies referenced in this document are the trademarks, service marks and/or trade names of their respective holders.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience