LNP™ ELCRES™ CRX COPOLYMER RESINS

IMPROVED CHEMICAL RESISTANCE MATERIALS FOR MEDICAL ENCLOSURES AND HOUSINGS

With patient safety at the forefront, the healthcare industry is mobilizing to address the concerns of increasing patient Infections associated with medical care, known as hospital-acquired infections (HAIs). To help meet this challenge, medical equipment and high touch surfaces in patient care settings are repeatedly wiped down with increasingly aggressive chemical disinfectants.

NEED FOR IMPROVED CHEMICAL RESISTANCE

Manufacturers of medical equipment for patient monitoring, imaging, diagnostic, fluid and medication delivery need materials that offer improved chemical resistance to the more aggressive disinfectants used today in healthcare settings.

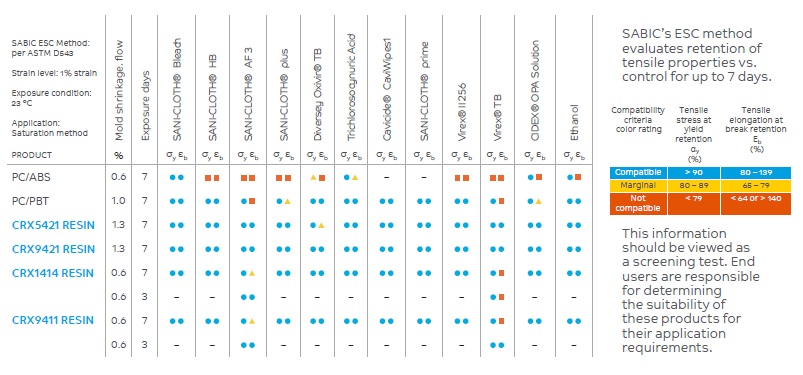

CHEMICAL RESISTANCE DATA – ENVIRONMENTAL STRESS CRACKING (ESC) PERFORMANCE

Compared to traditional PC, ABS, PBT and co-polyester resins and blends – which are potentially incompatible with highly aggressive disinfectants such as quaternary ammonium compounds – the new LN ELCRES CRX resins can help prevent stress cracking and mitigate crack propagation.

PLASTICS DETERMINATION OF RESISTANCE TO ENVIRONMENTAL STRESS CRACKING (ESC) METHOD

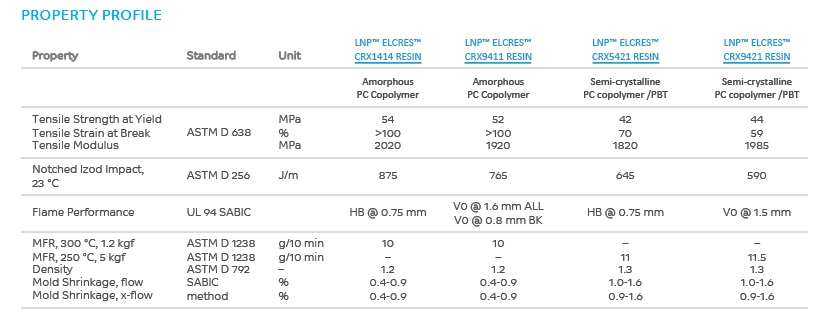

PERFORMANCE PROPERTIES

LNP ELCRES CRX copolymer resins are a new family of polycarbonate copolymers that can provide improved chemical resistance. These resins are based on unique copolymer building block blends offering a combination of:

POTENTIAL APPLICATIONS – MEDICAL EQUIPMENT HOUSINGS AND ENCLOSURES

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

THE MATERIALS, PRODUCTS AND SERVICES OF SAUDI BASIC INDUSTRIES CORPORATION (SABIC) OR ITS SUBSIDIARIES OR AFFILIATE S (“SELLER”) ARE SOLD SUBJECT TO SELLER’S STANDARD CONDITIONS OF SALE, WHICH ARE AVAILABLE UPON REQUEST. INFORMATION AND RECOMMENDATIONS CONTAINED IN THIS DOCUMENT ARE GIVEN IN GOOD FAITH. HOWEVER, SELLER MAKES NO EXP RESS OR IMPLIED REPRESENTATION, WARRANTY OR GUARANTEE ( i ) THAT ANY RESULTS DESCRIBED IN THIS DOCUMENT WILL BE OBTAINED UNDER END USE CONDITIONS, OR (ii) AS TO THE EFFECTIVENESS OR SAFETY OF ANY DESIGN OR APPLICATION INCORPORATING SELLER’S MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS. UNLESS OTHERWISE PROVIDED IN SELLER’S STANDARD CONDITIONS OF SALE, SELLER SHALL NOT BE RESPONSIBLE FOR ANY LOSS RESULTING FROM ANY USE OF ITS MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS DESCRIBED IN THIS DOCUMENT. Each user is responsible for making its own determination as to the suitability of Seller’s materials, products, services or recommendations for the user’s particular use through appropriate end use and other testing and analysis. Nothing in any document or oral statement shall be deemed to alter or waive any provision of Seller’s Standard Condit ions of Sale or this Disclaimer, unless it is specifically agreed to in a writing signed by Seller. Statements by Seller concerning a possible use of any material, product, service or design do not, are not intended to, and should not be construed to grant any license under any patent or other intellectual property right of Seller or as a recommendation for the use of any material, product, service or design in a manner that infringes any patent or other intellectual property right.

SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates, unless otherwise noted.

© 2023 Saudi Basic Industries Corporation (SABIC). All Rights Reserved.

Any brands, products or services of other companies referenced in this document are the trademarks, service marks and/or trade names of their respective holders.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience