Break free from Fluoropolymers. Discover the potential of SILTEM Resins.

Looking for a fluoropolymer alternative that can take the heat in high performance wire & cable applications? Discover the potential of SILTEM™ resins. Non-halogenated, non-fluorinated SILTEM resins can provide high-heat, chemical and flame resistance - plus flexibility and strength.

Whether you’re considering SILTEM resins for potential use in high temperature wire and cable insulation, jacketing, heat shrink tubes, tubing or other applications, we’re here to help. Contact us now to discuss your application requirements.

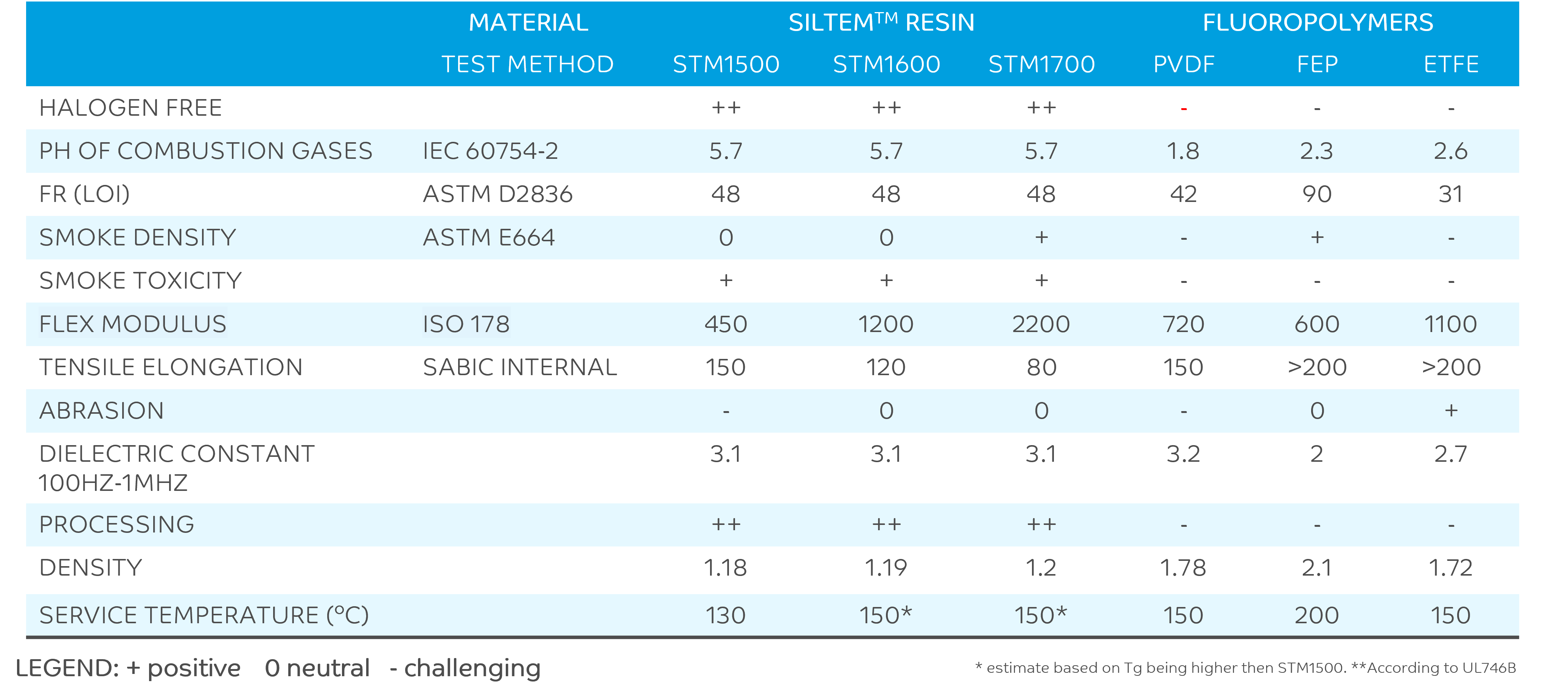

How does SILTEM™ resin compare to fluoropolymers?

Fluoropolymers like PVDF, ETFE, and FEP are used in diverse applications due to their durability (heat, chemical, and UV resistance). However, fluoropolymers are under increasing regulatory pressure due to their use of fluorosurfactants and the potential negative environmental impact of PFAS, commonly referred to as “Forever Chemicals”.

SILTEM resins are non-fluorinated amorphous copolymers with no intentionally added PFAS. SILTEM resins provide a combination of excellent high heat performance, non-halogenated flame retardancy (FR), durability without using fluorosurfactants, and easy processability via extrusion or injection molding. SILTEM material is also resistant to chemicals, UV degradation and radiation.

Compared to fluoropolymers, SILTEM resins can offer the potential for greater production output thanks to ease of processing, and up to a 40% weight reduction due to its lower density profile. The higher specific gravity of fluoropolymers can lead to increased weight and cost per part. Contact us for additional property and performance data.

Process and cost efficiency of SILTEM resins vs. fluoropolymers

• Ease of processing – greater production output potential

• Low corrosivity - improved cost of ownership potential

• Low density – up to 40% lower weight parts

See comparative property data for SILTEM resins versus fluoropolymers below.

SILTEM™ Resin Material Properties

SILTEM resin is an amorphous polyetherimide siloxane (PEI Si) copolymer that is easily extrudable. The combination of silicone elastomer with ULTEM™ resin provides flexibility with high heat performance. SILTEM resin standard grades include:

- STM1500: Highest flexibility, lowest heat

- STM1600: Medium flexibility, medium heat

- STM1700: Lowest flexibility, highest heat

SILTEM resins can offer a tailorable combination of strength, flexibility, heat resistance and chemical resistance to help meet your application requirements. These materials are colorable with SILTEM resin-based masterbatches.

We can offer more than materials

SABIC Specialties business can offer more than just materials. We stay ahead of the game by developing new products to keep up with the latest regulatory, scientific, and consumer trends. And we’re always looking for new ways to add value to your experience.

We invite you to work with us in a personal and collaborative approach. Our team is well-equipped to support your product development teams with our knowledge of materials, design, application development and testing.

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

ANY SALE BY SABIC, ITS SUBSIDIARIES AND AFFILIATES (EACH A “SELLER”), IS MADE EXCLUSIVELY UNDER SELLER’S STANDARD CONDITIONS OF SALE (AVAILABLE UPON REQUEST) UNLESS AGREED OTHERWISE IN WRITING AND SIGNED ON BEHALF OF THE SELLER. WHILE THE INFORMATION CONTAINED HEREIN IS GIVEN IN GOOD FAITH, SELLER MAKES NO WARRANTY, EXPRESS OR IMPLIED, INCLUDING MERCHANTABILITY AND NONINFRINGEMENT OF INTELLECTUAL PROPERTY, NOR ASSUMES ANY LIABILITY, DIRECT OR INDIRECT, WITH RESPECT TO THE PERFORMANCE, SUITABILITY OR FITNESS FOR INTENDED USE OR PURPOSE OF THESE PRODUCTS IN ANY APPLICATION.

Each customer must determine the suitability of seller materials for the customer’s particular use through appropriate testing and analysis. No statement by seller concerning a possible use of any product, service or design is intended, or should be construed, to grant any license under any patent or other intellectual property right. SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates, unless otherwise noted.

© 2025 Saudi Basic Industries Corporation (SABIC). All Rights Reserved.

Any brands, products or services of other companies referenced in this document are the trademarks, service marks and/or trade names of their respective holders.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience