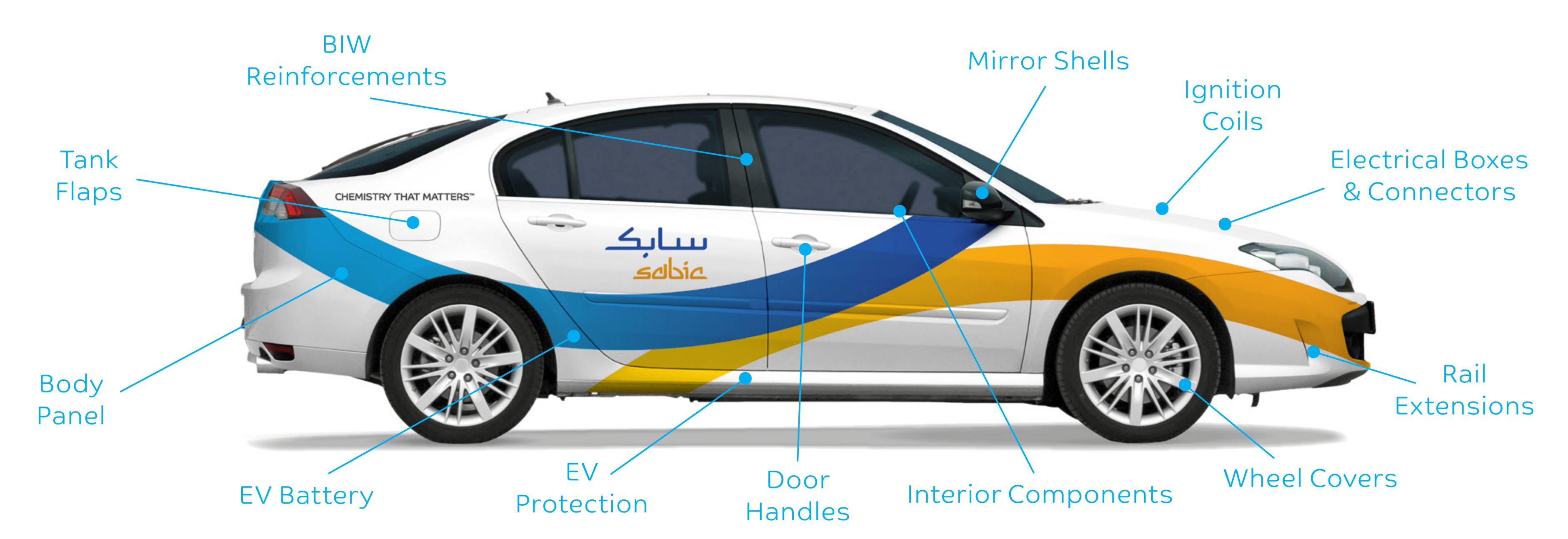

NORYL™ RESIN AUTOMOTIVE SOLUTIONS FOR STRUCTURAL, ELECTRIC VEHICLE BATTERY, ELECTRIC VEHICLE PROTECTION, AND INLINE PAINTING APPLICATIONS

NORYL™ AND NORYL GTX™ RESINS CAN OFFER UNIQUE SOLUTIONS TO THE AUTOMOTIVE INDUSTRY

The NORYL™ resin family consists of multiple blends of polyphenylene ether (PPE) with complementary thermoplastics. NORYL resin is an amorphous blend of PPE with polystyrenes and it is widely used in ignition coils, sensors and battery housings. NORYL GTX resin is a semi-crystalline blend with polyamides and offers multiple commercialized solutions across internal combustion engine, hybrid and electric vehicles.

NORYL GTX™ resin combines the inherent benefits of PPE (robust flame retardance, heat resistance, excellent dimensional stability, low creep) with the benefits of PA (chemical resistance, flow and impact resistance). The result is a chemically resistant material with the stiffness, impact resistance and heat performance required for inline painting.

The low density of unfilled NORYL GTX resin can provide part-weight savings of up to 25% over glass or mineral filled resins.

Additionally, the low specific gravity of NORYL GTX resin makes it a candidate resin for significant lightweighting versus steel. Potential applications for steel replacement include exterior body panels, in or online painted surfaces, and battery protection.

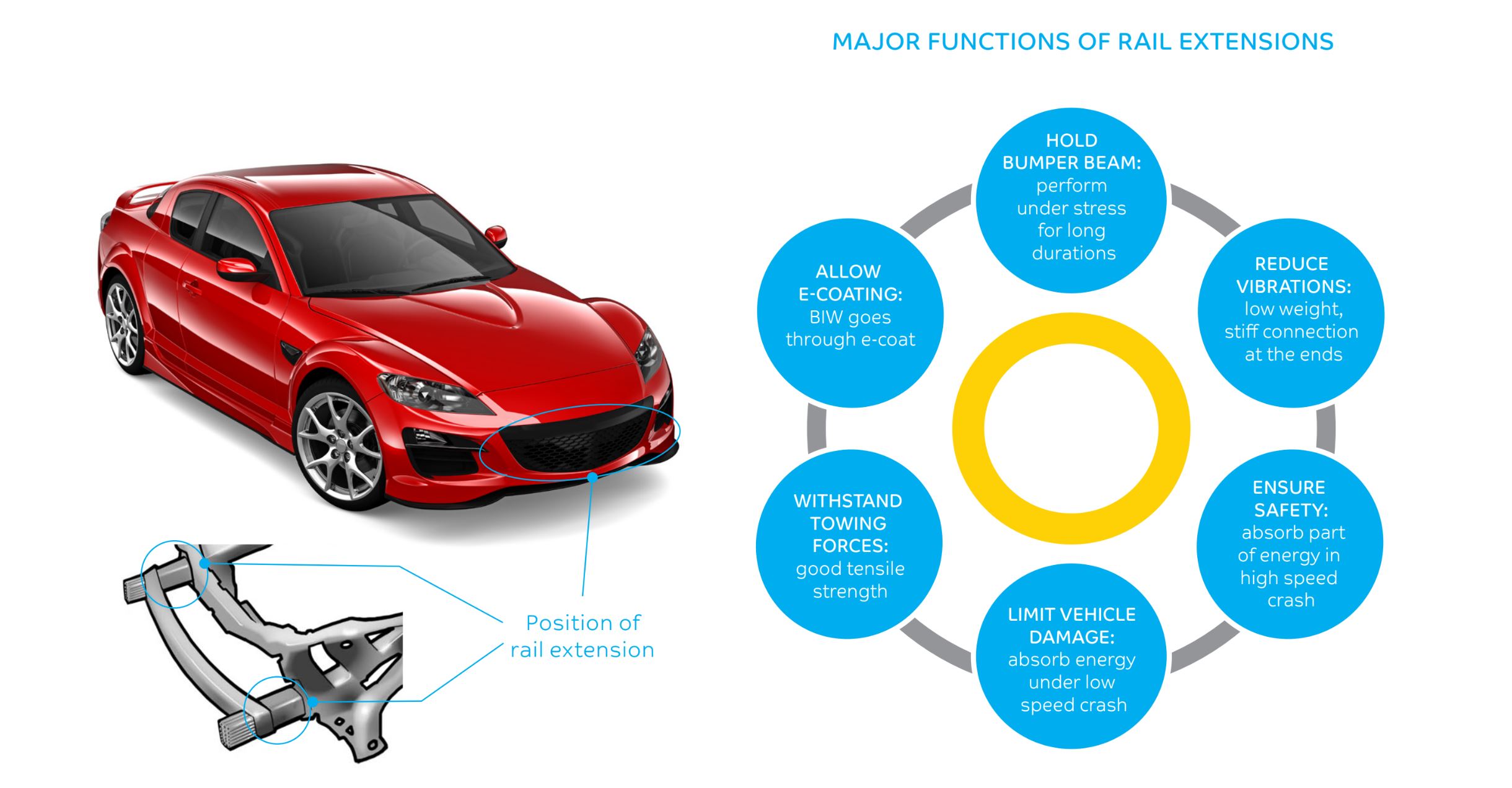

NORYL GTX™ RESIN: RAIL EXTENSIONS

RAIL EXTENSIONS PLAY A CRUCIAL ROLE IN ENERGY ABSORPTION DURING FRONT AND REAR CRASHES

POTENTIAL BENEFITS OF NORYL GTX™ RESIN VS. STEEL

- Weight reduction of 50% vs. steel in some cases –without compromising performance

- Up to 3.5 kg per vehicle

- 2 kg weight out from bumper

- Part integration - ease of assembly

- Reduced overall tooling cost

- Reduced total system cost

- Single tool for LH & RH

- Comparable low-speed and high-speed crash performance

- 20% better front crash performance

- Meets NVH (noise, vibration and harshness) and towing requirements

- E-coat Capable

- Potential to reduce packaging space

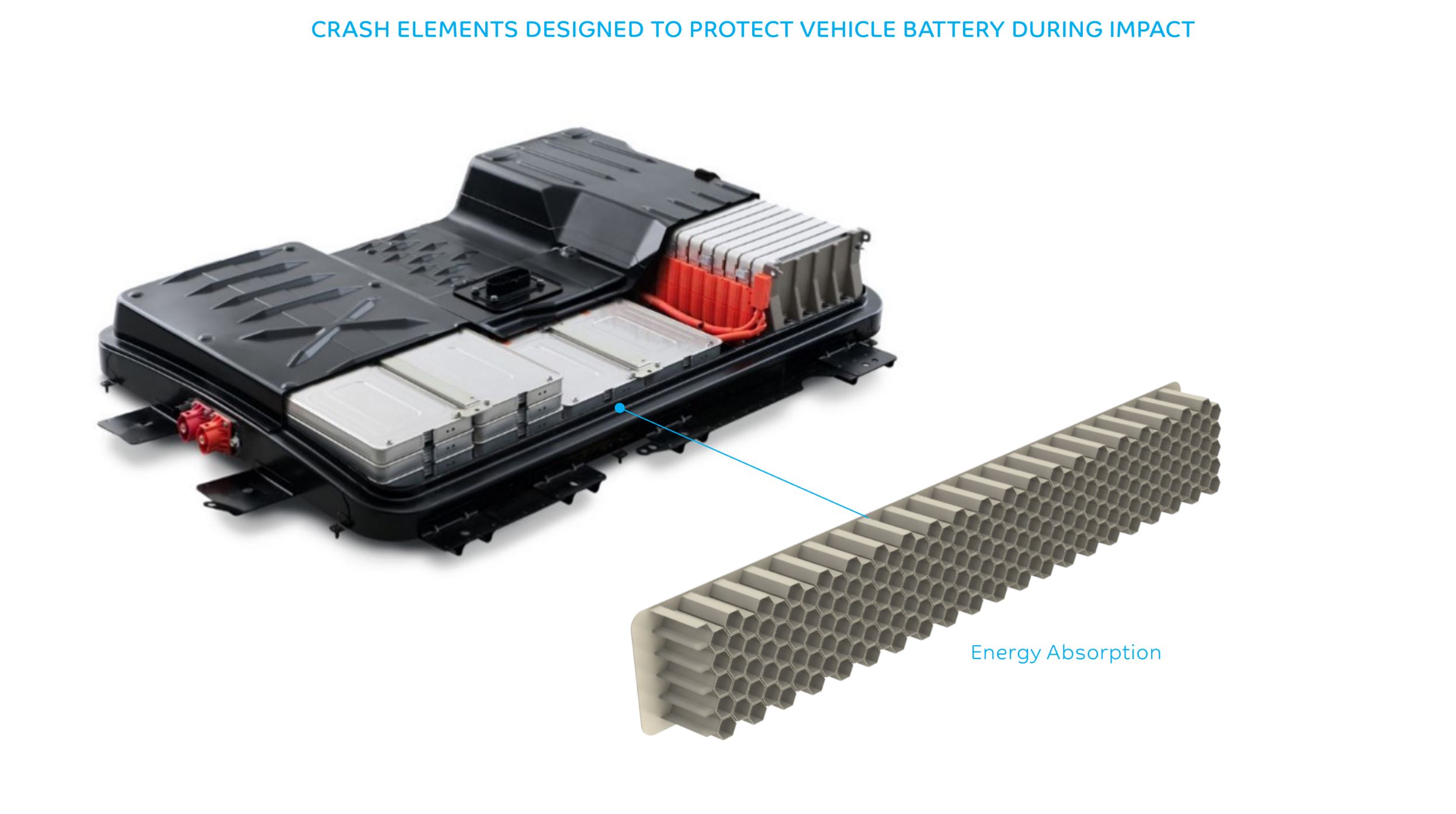

NORYL GTX™ RESIN: LIGHTWEIGHT BATTERY PROTECTION SOLUTIONS FOR ELECTRIC VEHICLES

POTENTIAL BENEFITS OF NORYL GTX RESIN

- Up to 40 to 60% weight reduction compared to multi-piece metal reinforcement

- Up to 20 kg weight out

- High efficiency of energy absorption

- Can be tuned for desired force level and balance strength & stiffness

- Single piece solution, ease of assembly, e-coat capable

- Metal flanges over-molded with plastic honeycombs – direct welding to rocker

- Cost competitive

- Significant weight out at comparable cost vs incumbent metal solutions

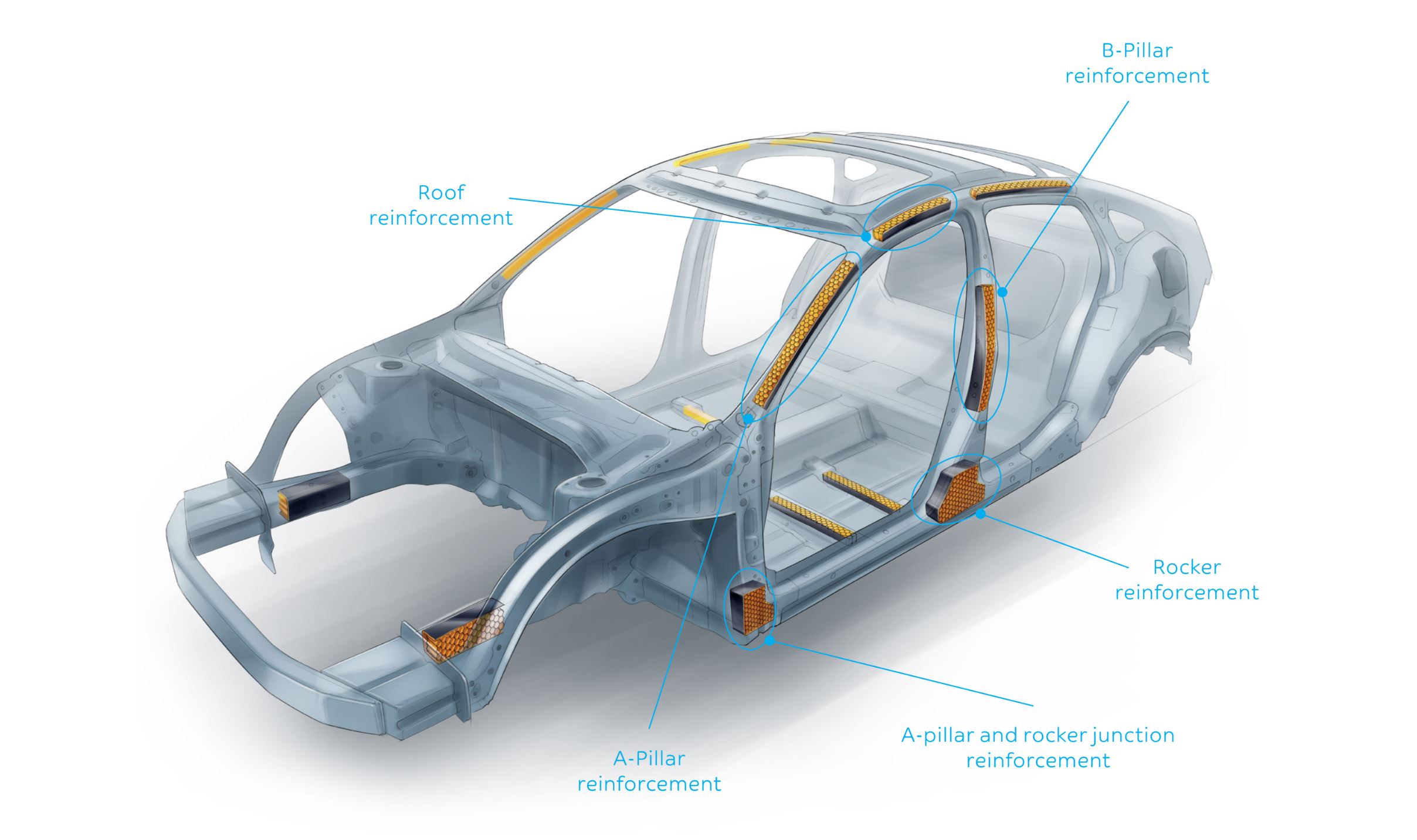

NORYL GTX™ RESIN: LIGHTWEIGHT BODY IN WHITE REINFORCEMENT SOLUTIONS

POTENTIAL BENEFITS OF NORYL GTX RESIN

- Metal-plastic hybrid solutions for reinforcement in BIW

- Up to 30-40% mass reduction from each reinforcement

- Comparable performance to high strength steel

- Ease of assembly

- 5-10 kgs total weight saving potential from 10-12 reinforcements in BIW

- Heat resistance that withstands the e-coat painting process

NORYL GTX™ RESIN AUTOMOTIVE SOLUTIONS

DESIGN WITH CONFIDENCE

Inherently conductive NORYL GTX™ resins offer automotive OEMs major design advantages for large, high-precision body panels and complex fenders by allowing for existing process integration including high-heat inline painting systems… all while providing outstanding aesthetics and performance.

NORYL GTX™ conductive resins have a low coefficient of thermal expansion (CTE) allowing for good dimensional stability and flush management with other plastic and metal adjoining parts.Many grades in this resin family are designed to withstand temperatures in excess of 180 degrees C to meet the demanding requirements of e-coat paint lines.

Specifically developed for on-or- inline painted fenders and exterior body panels, this unique thermoplastic material may also be utilized for smaller parts such as tank flaps, grilles and mirror housings in primerless electrostatic painting, powder coat systems, and solvent- based paint systems.

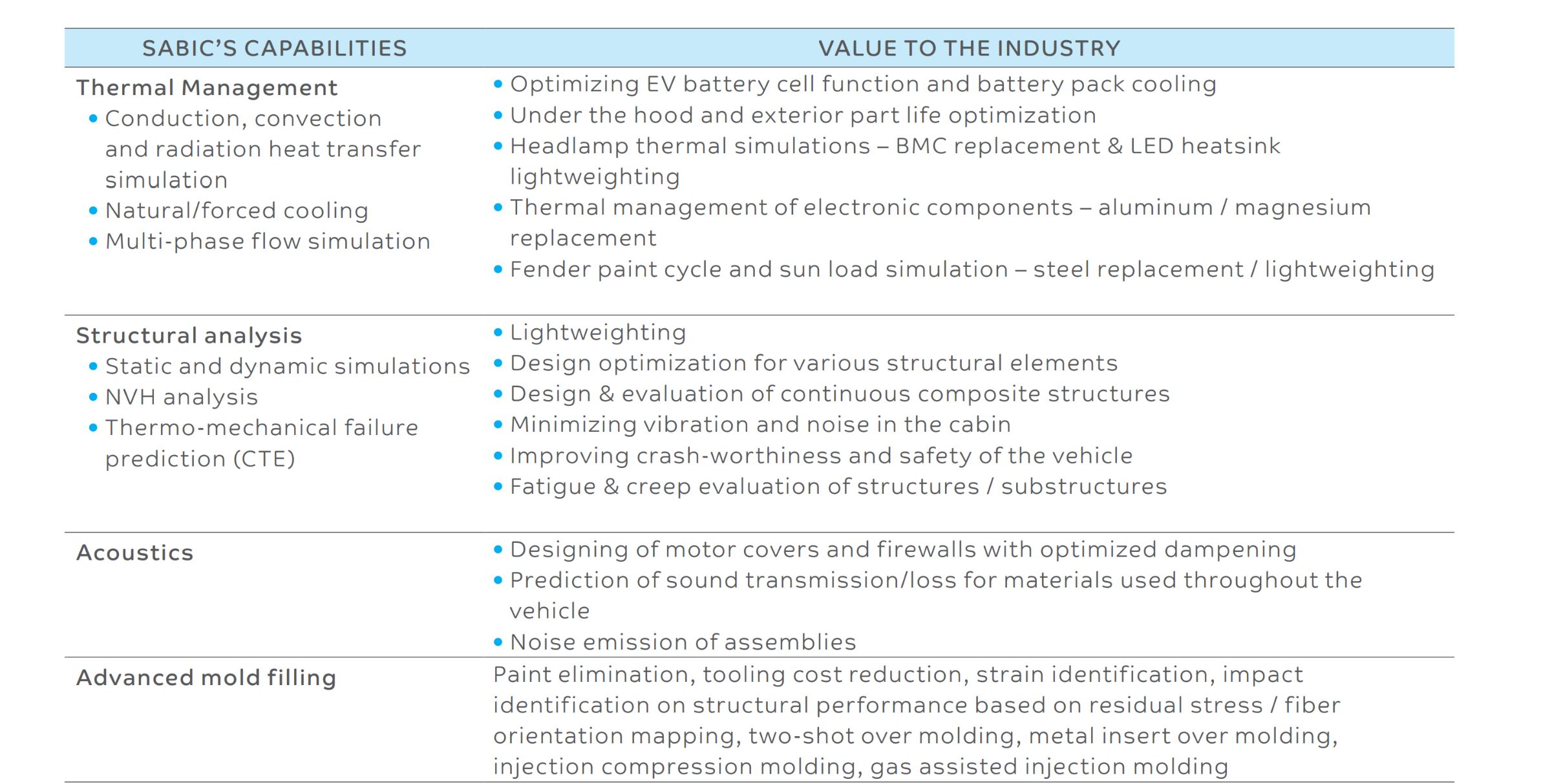

SABIC’S PREDICTIVE ENGINEERING CAPABILITIES FOR THE AUTOMOTIVE INDUSTRY

SABIC offers industry-leading engineering support to the automotive industry through our Global Application Technology (GApT) capabilities. From concept development, to simulation and prototyping, and even final part testing, we work alongside our customers to accelerate the material selection process and help increase speed to market. Our predictive engineering capabilities address both EV and ICE vehicle development needs, and are utilized worldwide by engineers at major OEMs and many emerging manufacturers.

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

DISCLAIMER: THE MATERIALS, PRODUCTS AND SERVICES OF SAUDI BASIC INDUSTRIES CORPORATION (SABIC) OR ITS SUBSIDIARIES OR AFFILIATES (“SELLER”) ARE SOLD SUBJECT TO SELLER’S

STANDARD CONDITIONS OF SALE, WHICH ARE AVAILABLE UPON REQUEST. INFORMATION AND RECOMMENDATIONS CONTAINED IN THIS DOCUMENT ARE GIVEN IN GOOD FAITH. HOWEVER, SELLER MAKES NO EXPRESS OR IMPLIED REPRESENTATION, WARRANTY OR GUARANTEE (i) THAT ANY RESULTS DESCRIBED IN THIS DOCUMENT WILL BE OBTAINED UNDER END-USE CONDITIONS, OR (ii) AS TO THE EFFECTIVENESS OR SAFETY OF ANY DESIGN OR APPLICATION INCORPORATING SELLER’S MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS. UNLESS OTHERWISE PROVIDED IN SELLER’S STANDARD CONDITIONS OF SALE, SELLER SHALL NOT BE RESPONSIBLE FOR ANY LOSS RESULTING FROM ANY USE OF ITS MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS DESCRIBED IN THIS

DOCUMENT. Each user is responsible for making its own determination as to the suitability of Seller’s materials, products, services or recommendations for the user’s particular use through appropriate end-use and other testing and analysis. Nothing in any document or oral statement shall be deemed to alter or waive any provision of Seller’s Standard Conditions of Sale or this Disclaimer, unless it is specifically agreed to in a writing signed by Seller. Statements by Seller concerning a possible use of any material, product, service or design do not, are not intended to, and should not be construed to grant any license under any patent or other intellectual property right of Seller or as a recommendation for the use of any material, product, service or design in a manner that infringes any patent or other intellectual property right.

SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates.

© 2023 Copyright SABIC. All rights reserved.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience