NORYL™ RESIN BIOFOULING RESISTANCE PROPERTIES

Biofouling or biological fouling can be described as the accumulation of microorganisms, plants or algae on wetted surfaces. This leads to loss of efficiency of membranes and can shorten the lifetime and performance of pipes used in the transportation of drinking water. NORYL™ resin has unique properties, similar to stainless steel, that result in very low biomass production potential along with excellent hydrolytic stability even in chlorinated environments.

TYPICAL INDUSTRY REQUIREMENTS

- Hygienic and disinfectant (e.g. chlorine dioxide) resistant solution

- Reliable and long term part operation

- Potable water certified applications

NORYL RESIN VALUE

- Low biomass production potential

- Low surface roughness achievable

- High hydrophobicity

- Excellent chlorine resistance

- Potable water approved

NORYL RESIN EXHIBITS BIOFOULING RESISTANCE THAT IS EVEN LOWER THAN STAINLESS STEEL

The table on the right shows the biomass production potential (BPP) per material, using Test Method 1 for EN 16421:2014.

The growth of e.g. Legionella pneumophila, which causes Legionnaires’ disease, begins when the biomass production potential is >400 pg ATP/cm²*.

Other factors that influence biofouling:

- Surface roughness

- Degree of hydrophobicity

- Leaching of ingredients from plastics

Material | BPP [pg ATP/cm²]* |

| Stainless Steel | 45 - 50 |

| NORYL resin, unfilled | 40 |

| NORYL resin, glass filled | 40 |

| Copper | 100 - 193 |

| PVC-C | 119 - 417 |

| PVC-U | 82 - 365 |

| PVC-P | > 10.000 |

| EPDM | 4.129 --> 10.000 |

| SBR | 6.281 --> 10.000 |

| PE 40 | 463 - 1.542 |

| PE 80 | 355 - 1.750 |

| PE 100 | 544 - 1.750 |

| PP | 352 - 1.393 |

* Source : “Hydro !” , Edition 7, 2015 Article “BIOLOGISCHE ACTIVITEIT IN DRINKWATER” from KWR Institute. pg ATP/cm² = Picogram Adenosine TriPhospate per cubic centimeter

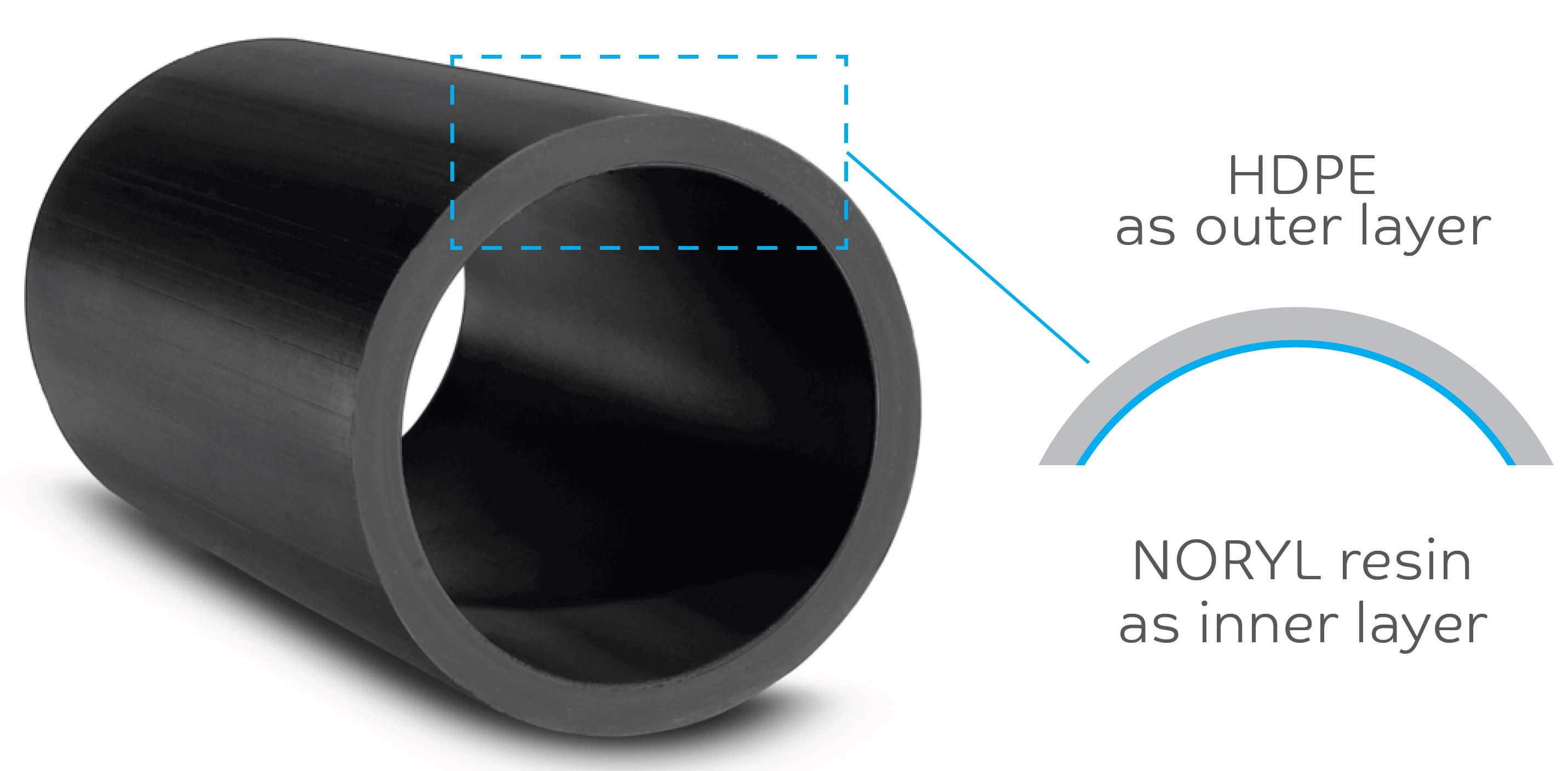

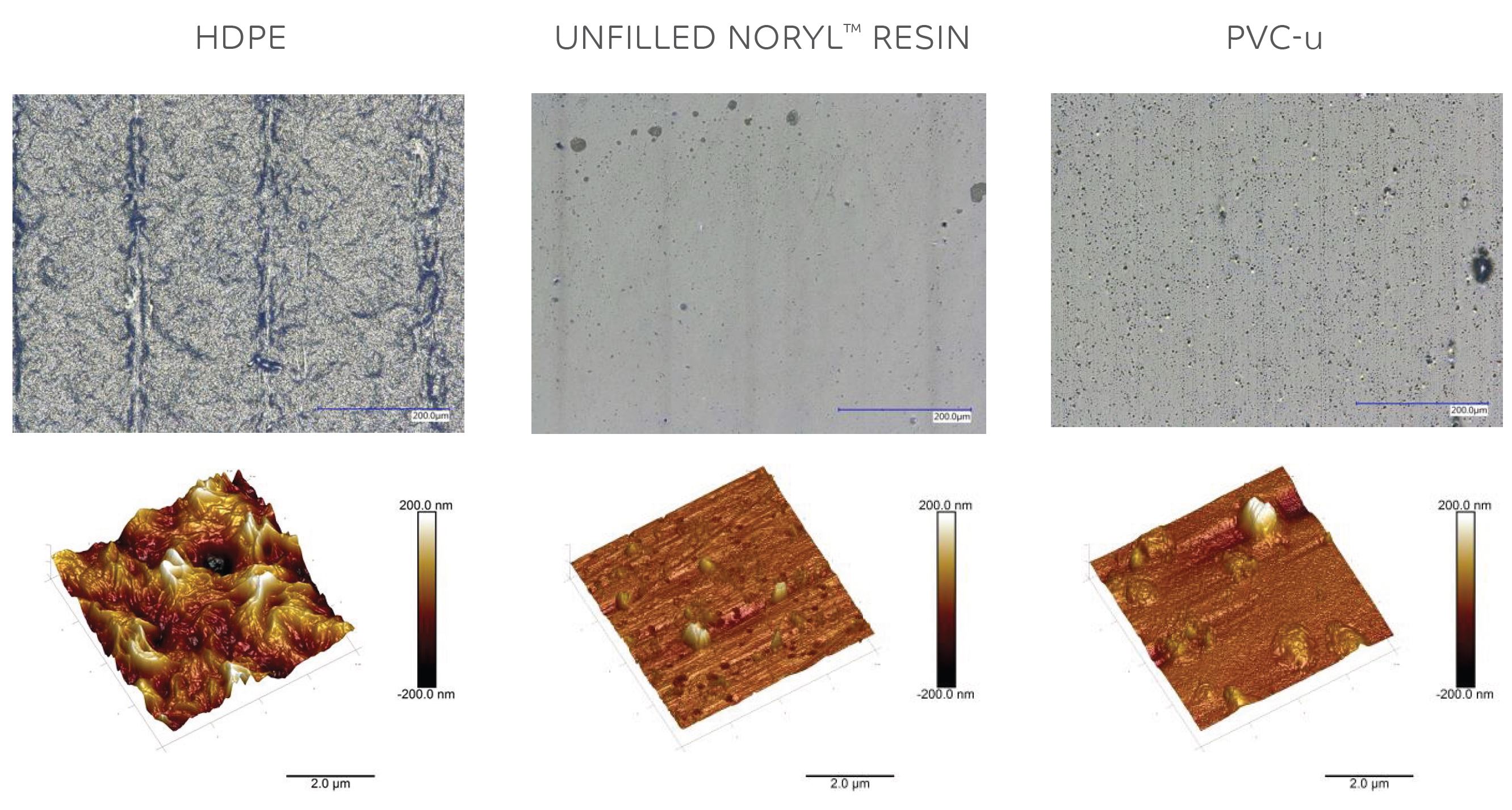

A comparison of surface roughness measured with optical and atomic force microscopy shows that pipes extruded with NORYL™ resin can have smoother surfaces when compared to traditional pipe materials such as HDPE or PVC u.

THE SMOOTHER SURFACE POTENTIALLY REDUCES THE RISK OF BIOACCUMULATION

| Material | Rq (nm) | Ra (nm) |

| HDPE | 69 | 54 |

| NORYL™ | 14 | 7 |

| PVC | 22 | 11 |

Table: Measured Surface Roughness

NORYL™ RESIN CHARACTERISTICS SUMMARY

- Low biomass p roduction potential

- Smooth surface achievable

- Excellent hydrolytic stability

- Excellent chlorine based disinfectant resistance

- Potable water approved

- Extrusion and injection molding grades available

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

DISCLAIMER: THE MATERIALS, PRODUCTS AND SERVICES OF SAUDI BASIC INDUSTRIES CORPORATION (SABIC) OR ITS SUBSIDIARIES OR AFFILIATES (“SELLER”) ARE SOLD SUBJECT TO SELLER’S STANDARD CONDITIONS OF SALE, WHICH ARE AVAILABLE UPON REQUEST. INFORMATION AND RECOMMENDATIONS CONTAINED IN THIS DOCUMENT ARE GIVEN IN GOOD FAITH. HOWEVER, SELLER MAKES NO EXPRESS OR IMPLIED REPRESENTATION, WARRANTY OR GUARANTEE (i) THAT ANY RESULTS DESCRIBED IN THIS DOCUMENT WILL BE OBTAINED UNDER END-USE CONDITIONS, OR (ii) AS TO THE EFFECTIVENESS OR SAFETY OF ANY DESIGN OR APPLICATION INCORPORATING SELLER’S MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS. UNLESS OTHERWISE PROVIDED IN SELLER’S STANDARD CONDITIONS OF SALE, SELLER SHALL NOT BE RESPONSIBLE FOR ANY LOSS RESULTING FROM ANY USE OF ITS MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS DESCRIBED IN THIS DOCUMENT. Each user is responsible for making its own determination as to the suitability of Seller’s materials, products, services or recommendations for the user’s particular use through appropriate end-use and other testing and analysis. Nothing in any document or oral statement shall be deemed to alter or waive any provision of Seller’s Standard Conditions of Sale or this Disclaimer, unless it is specifically agreed to in a writing signed by Seller. Statements by Seller concerning a possible use of any material, product, service or design do not, are not intended to, and should not be construed to grant any license under any patent or other intellectual property right of Seller or as a recommendation for the use of any material, product, service or design in a manner that infringes any patent or other intellectual property right.

SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates. © 2023 Copyright SABIC. All rights reserved.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience