MATERIAL SOLUTIONS FOR POINT OF CARE DEVICES

PROVIDING MATERIALS & TECHNOLOGY

SOLUTIONS FOR POINT OF CARE

CONNECTED DEVICES

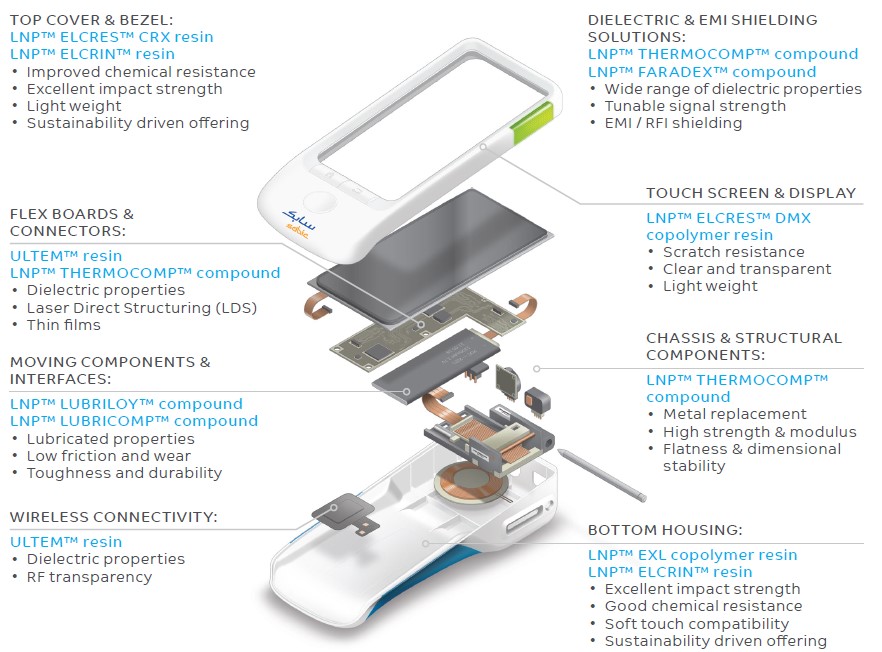

The need for improved chemical resistance and long-term durability is an important factor for point of care devices. Hospitals, labs and healthcare providers will continue to use aggressive cleaners to ensure patient safety and provide protection from virus and disease. Using advanced thermoplastics can help improve the performance of your medical device and enhance your design. Our materials can also help you address industry requirements such as biocompatibility, formulation lock, compatibility with disinfectants and long-term durability.

SABIC's Specialties business provides a wide range of healthcare solutions that offer biocompatible materials, improved chemical resistance, healthcare color packages, autoclavability at 121 °C and 134 °C and long-term durability. We support our materials with value-added services, including design support, mold-flow analysis, testing and predictive engineering capabilities, which are available for each step of your application development process.

PRODUCT LINE CARD

ULTEMTM resin

PEI

• High heat resistance to 221 0C

• Superior unfilled strength and stiffness

• Great isotropic dimensional stability

• Excellent UV, hydrolytic and chemical

stability

• Near infrared transparency

• Robust electrical & dielectric properties

• Inherent flame retardancy / low smoke

generation

• Outstanding optical properties

• Mirror-like, direct vacuum metallization

LNPTM LUBRICOMPTM & LUBRILOYTM compounds

• Inherent lubricity through a broad range

of lubricants

• Can help extend product life and reduce

friction and wear rates of plastic parts

• Based on more than 25 engineering

thermoplastics

• Broad range of attributes including

excellent dimensional stability, low

wear, enhanced mechanical and thermal

properties, flame retardancy and fatigue

endurance

• Flame retardancy, non-Br & Cl FR

compounds

• Colorability, wide range ofopaque colors

• Eliminates secondary lubrication which

helps reduce cost

• Can provide design freedom, part

consolidation and improved production

economies

LNPTM ELCRINTM resin

Sustainability driven solution utilizing ELCRIN iQ

upcycling technology; offering similar chemical

resistance performance compared to virgin PBT

compounds

• Better carbon/energy footprint

• Recycled content certified by SCS Global

• Comparable properties tovirgin PBT and

wide color space

• Food contact compliance options possible

• Healthcare management of change policy

LNPTM ELCRESTM DMX copolymer resins

• Transparency and clarity

• UV stabilized

• Improved scratch resistance compared to

homopolymer PC

LNPTM ELCRESTM CRX copolymer resins

• Chemical resistance

• Biocompatibility

• Enhanced mechanical, optical, thermal and

weathering properties.

• Scratch resistance, stiffness, heat

resistance

• Environmentally conforming flame

retardancy

LNPTM EXL copolymer resin

High impact PC/Siloxane

• Excellent low temperature impact

resistance

• Weatherability

• Improved chemical resistance

• Excellent processability

• Impact resistance retention upon long

term heat and humidity aging

• Non-Br & Cl FR grades

• Wide range of colors including VISUALFXTM

resin

• Excellent laser weldability

LNPTM THERMOCOMPTM compounds

Structural materials

• Superior filled strength and stiffness

• Closely-tuned engineering attributes

including strength, stiffness, chemical

resistance, flow properties, and

dimensional stability

• More than 25 different base resins,

including ULTEMTM resin, PEEK, PA, PPS,

and melt processible fluoropolymers

• Reinforcing additives including glass fiber,

carbon fiber, glass beads and various

minerals

• Colorability for improved aesthetics

• Laser Direct Structuring (LDS)

• Flame retardancy, Non-Br & Cl FR

compounds

LNPTM FARADEXTM compound

• Deep attenuation EMI/RFI shielding

capabilities between 40-60 dB and higher

from 30-1000 MHz

• Electrostatic discharge (ESD) control

• Mechanical properties similar to unfilled

base resins

• Flame retardancy, non-Br & Cl FR

compounds

• Eliminating secondary spray coating or

attachment of conductive fabrics

• Conductivity permeates the entire part

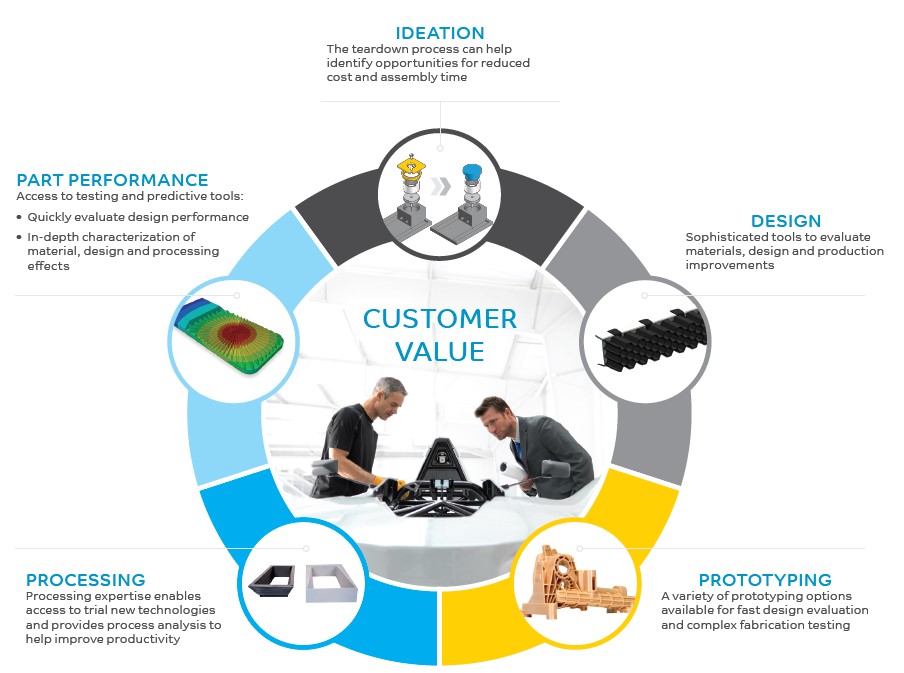

BRINGING VALUE TO CUSTOMERS

Our unique capabilities create opportunities for improved efficiency, material performance and productivity

CONTACT INFORMATION

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

Any sale by SABIC, its subsidiaries and affiliates (each a “seller”), is made exclusively under seller’s standard conditions of sale (available upon request) unless agreed otherwise in writing and signed on behalf of the seller. While the information contained herein is given in good faith, SELLER MAKES NO WARRANTY, EXPRESS OR IMPLIED, INCLUDING MER¬CHANTABILITY AND NONINFRINGEMENT OF INTELLECTUAL PROPERTY, NOR ASSUMES ANY LIABILITY, DIRECT OR INDIRECT, WITH RESPECT TO THE PERFORMANCE, SUITABILITY OR FITNESS FOR INTENDED USE OR PURPOSE OF THESE PRODUCTS IN ANY APPLICATION. Each customer must determine the suitability of seller materials for the customer’s particular use through appropriate testing and analysis. No statement by seller concerning a possible use of any product, service or design is intended, or should be construed, to grant any license under any patent or other intellectual property right. SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates, unless otherwise noted.

© 2023 Saudi Basic Industries Corporation (SABIC). All Rights Reserved.

SABIC and brands marked with TM are trademarks of SABIC or affiliates.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience