LNP THERMOCOMP SOLUTIONS FOR RF DATA CONNECTORS

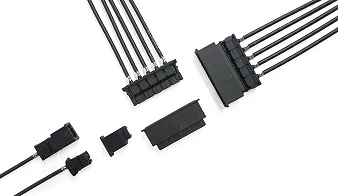

With advancements in telematics and automotive communications technology, RF communication systems have become integral components in today’s automotive, trucking, watercraft, motorcycle, and off-road construction markets. Antenna, ADAS, GPS, Bluetooth, satellite radio, onboard Internet access, HD image and central control, remote diagnosis, 5G and autonomous driving will drive the rapid growth of the market of RF connectors.

LNP™ THERMOCOMP™ Z compounds with an affordable high heat resistance, good electrical properties (very low dk / df), excellent hydrolytic stability and the ability to use non-halogen FR packages, with excellent dimensional stability, good processability and low specific gravity.

Why do our customers use these compounds in RF Data connectors?

Inlet / Insulators:

LNP™ THERMOCOMP™ Z1C00XXP compound

Features

• Stable and low di-electrical properties

- Low relative permittivity (2,6 at 1MHz according to IEC 60250) and dissipation factor (0,001 at 1MHz according to IEC 60250)

- Stable properties over a broad range of frequencies, temperatures and humidity levels

• Tight dimensions due to good dimensional stability

• Injection moldable

Benefits

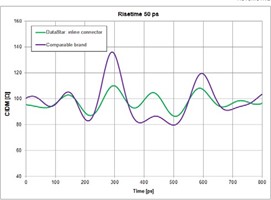

Hirschmann Automotive GmbH has designed a range of connectors suitable for automotive Ethernet up to 1 Gbps, called DataStar.

Using these resins, Hirschmann was able to optimize the impedance significantly and therefore extend the frequency range far beyond 1 GHz while maintaining low losses. This results in a better performance, higher signal integrity and lower Bit Error Rate (BER) in the harsh environment of automotive applications.

Connector housing:

LNP™ THERMOCOMP™ ZF006XXP compound

Features

• Ductility and hydrolytic stability

• Stable strength and dimensional stability with low moisture absorption

• Clear sound snap fitting

• Low creep under elevated ambient temperature

• UL94 V0 <1,5mm with non-halogenated FR

• Multi-color available

Benefits

• LNP™ THERMOCOMP™ Z compound might help to reduce or even eliminate crack issues

- Improved ductility at low temperatures vs reinforced polyamide (PA)

- Improved hydrolysis resistance vs polybutylene terephthalate (PBT)

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

DISCLAIMER: ANY SALE BY SABIC, ITS SUBSIDIARIES AND AFFILIATES (EACH A “SELLER”), IS MADE EXCLUSIVELY UNDER SELLER’S STANDARD CONDITIONS OF SALE (AVAILABLE UPON REQUEST) UNLESS AGREED OTHERWISE IN WRITING AND SIGNED ON BEHALF OF THE SELLER. WHILE THE INFORMATION CONTAINED HEREIN IS GIVEN IN GOOD FAITH, SELLER MAKES NO WARRANTY, EXPRESS OR IMPLIED, INCLUDING MERCHANTABILITY AND NONINFRINGEMENT OF INTELLECTUAL PROPERTY, NOR ASSUMES ANY LIABILITY, DIRECT OR INDIRECT, WITH RESPECT TO THE PERFORMANCE, SUITABILITY OR FITNESS FOR INTENDED USE OR PURPOSE OF THESE PRODUCTS IN ANY APPLICATION.

Each customer must determine the suitability of seller materials for the customer’s particular use through appropriate testing and analysis. No statement by seller concerning a possible use of any product, service or design is intended, or should be construed, to grant any license under any patent or other intellectual property right. SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates, unless otherwise noted.

© 2023 Saudi Basic Industries Corporation (SABIC). All Rights Reserved.

Any brands, products or services of other companies referenced in this document are the trademarks, service marks and/or trade names of their respective holders.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience