ULTEM™ AND EXTEM™ RESINS IN PHOTONICS

SABIC A GLOBAL LEADER IN CHEMICALS

Ranked among the world’s largest petrochemicals manufacturers, SABIC is a public company based in Riyadh, Saudi Arabia. For over 40 years, our ambition to define the future of petrochemicals and thermoplastics has yielded solutions for the challenges of today and helped our customers achieve their ambitions for a better tomorrow.

We believe the answer to some of the world’s biggest challenges lies in the natural human instinct to collaborate. We’re making sure we understand the megatrends that will impact on our lives in the years to come.

We are making a meaningful impact in the world and sustainability is a vital part of our core business strategy.

From enabling energy efficient high-bandwidth datacenters, to making cars and planes more fuel-efficient and helping conserve the world’s water supply, we find solutions to the challenges of today to help our customers achieve their ambitions and build a better tomorrow.

Together we’re making Chemistry that Matters™

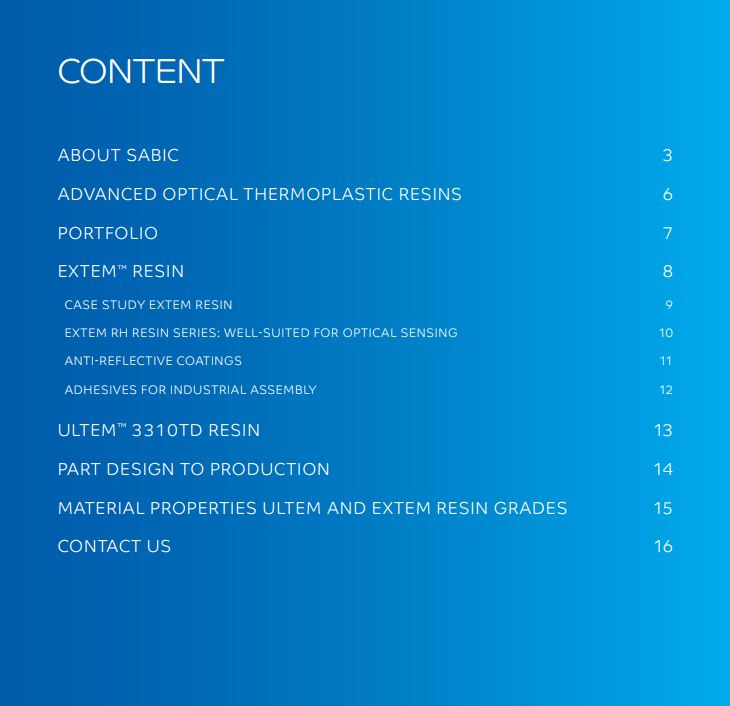

POTENTIAL BENEFITS OF SABIC’S ADVANCED OPTICAL THERMOPLASTIC RESINS

SABIC has several decades of history in supplying thermoplastic polymers in the opto-electronics industry. Optical elements in data communication and mobile applications play a critical role for seamless connectivity of electronic devices and back-end infrastructures.

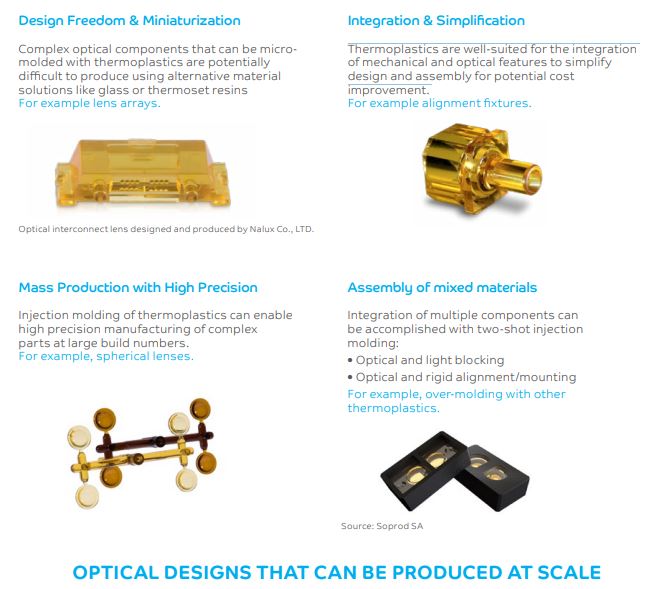

OUR PORTFOLIO MEETS VARIOUS REQUIREMENTS OF THE OPTICAL INDUSTRY

SABIC offers a broad portfolio of ULTEM™ and EXTEM™ resins to address material requirements for the photonics industry, including the ability to withstand the high heat of typical opto-electronic solder processes.

ULTEM Polyetherimide Resin

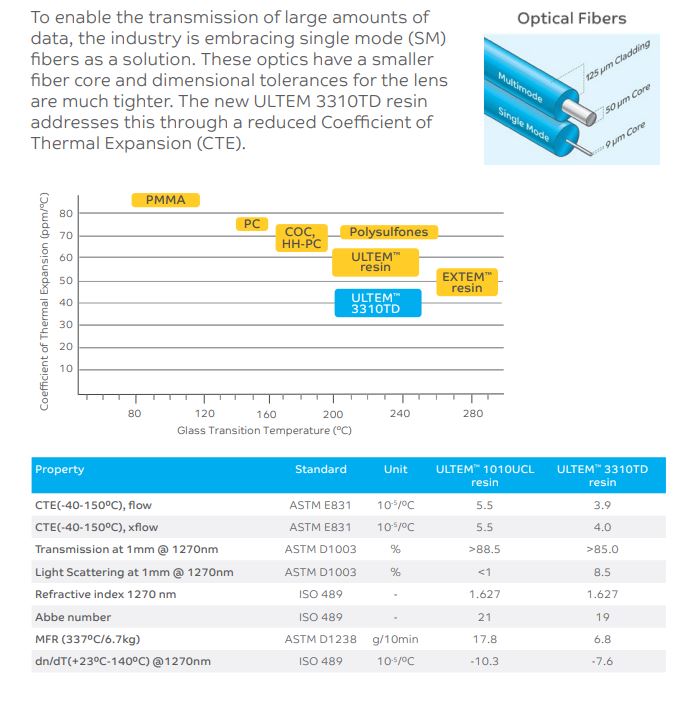

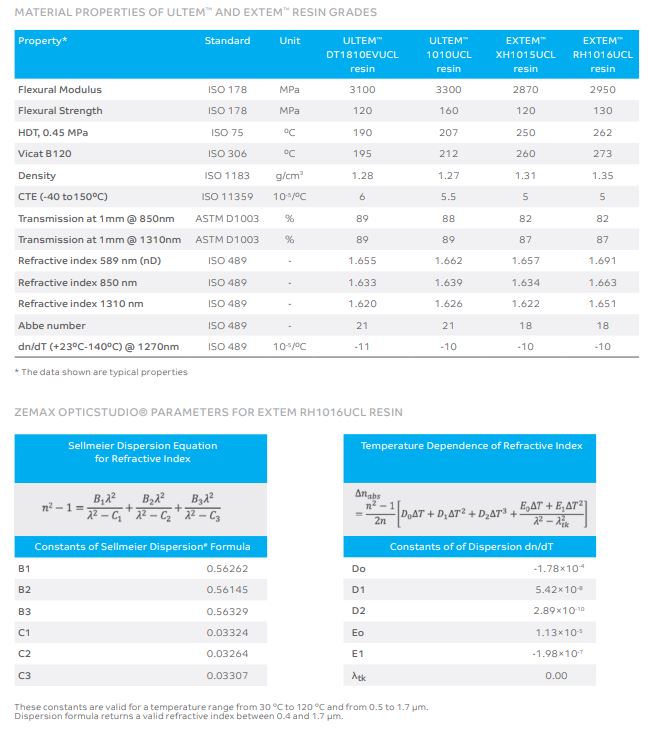

ULTEM resins are near infrared transparent, amorphous thermoplastic resins with a low thermal expansion coefficient (CTE). They have been used for (multi mode) optical lens assemblies in photonics for decades based on a perfect properties fit for this application area.

The new ULTEM 3310TD resin offers ~ 30% reduction in CTE while retaining optical transmission and is well-suited where extra tight alignment tolerances are required, like lenses for single mode optics in data centers.

EXTEM Polyimide Resin

EXTEM resins offer superior heat resistance with near infrared transparency.

They can maintain stiffness and dimensional stability for mounting of parts and modules in a PCB assembly with SAC/SMT reflow soldering (245 - 260°C) process according JEDEC J-STD-020A.

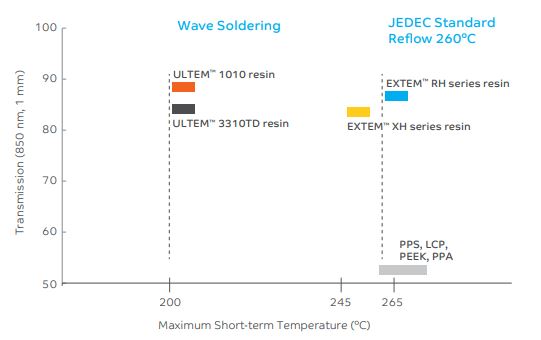

EXTEM™ RESIN WELL-SUITED FOR ONBOARD OPTICAL INTERCONNECTS

Trends in improved user experience, functionality and connectivity are driving both higher bandwidth and speed. Is the industry we know moving from pluggable to co-packaged solutions? Whichever path you follow, we might have the right material for you.

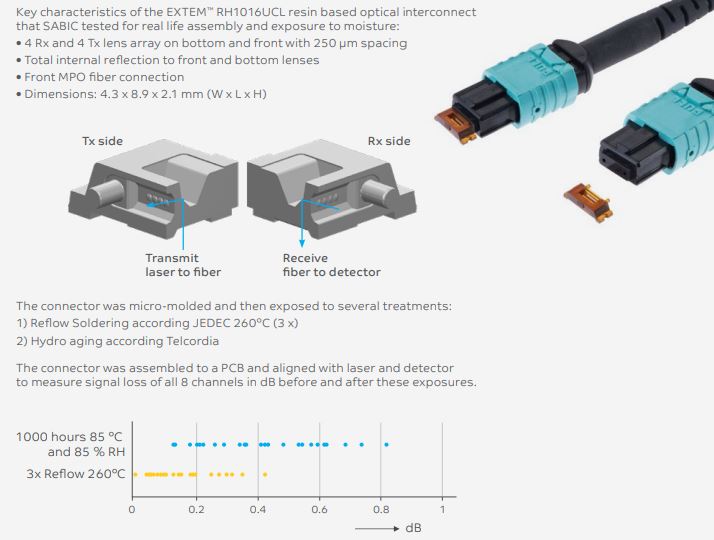

CASE STUDY EXTEM™ RESIN IMPACT OF REFLOW SOLDERING & HYDRO AGING

Key test results using 5 parts are shown in the graph above.

• After 3 times reflow, the optical interconnects show no blistering while maximum signal loss was only 0.4dB.

• Hydro aging for 1000 hours did not result in haziness or any other visual defect, and signal loss did not exceed 1 dB.

These results are well within OEM specifications that SABIC used as a reference.

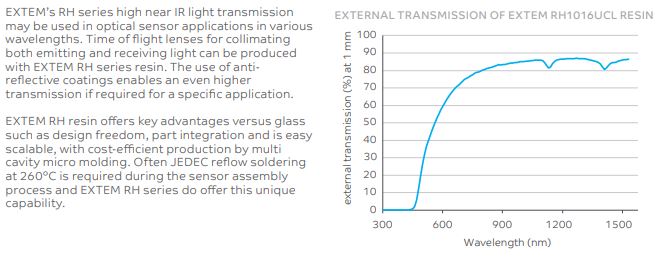

EXTEM™ RH RESIN SERIES WELL-SUITED FOR OPTICAL SENSING

Today, sensors are widely used in a growing number of applications. Some of these are proximity sensors, 3D sensing cameras and biometric monitoring devices. These application spaces keep growing at a high rate and upgraded functionalities require higher lens complexity.

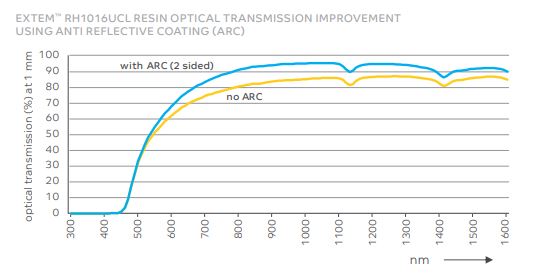

ANTI-REFLECTIVE COATINGS TO IMPROVE EXTEM™ RESIN OPTICAL TRANSMISSION

Anti-reflection coatings (ARC) reduce first surface reflection losses, improve contrast and boost the transmission through the optical surface. By applying these coatings on EXTEM™ resin, more light is transmitted through the lenses, enabling a higher sensitivity for optical sensors or lower signal losses for fiber optical connectors.

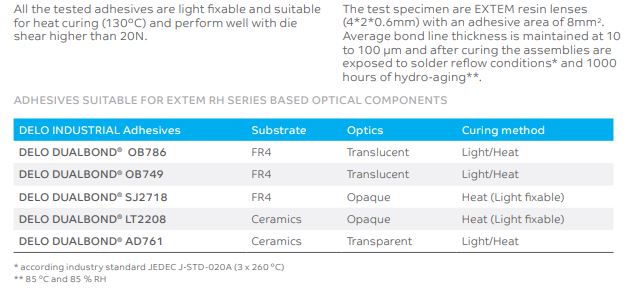

In the assembly of opto-electronic packages adhesives play a key role to bond lenses and substrates. Using mainstream assembly techniques for mass production of optical modules, SABIC tested a wide range of adhesives in collaboration with DELO. This includes transparent, low-outgassing and tension-equalizing adhesives to compensate for thermal expansion differences between EXTEM resin and substrates.

ULTEM™ 3310TD RESIN FOR POTENTIAL USE IN SINGLE MODE OPTICS

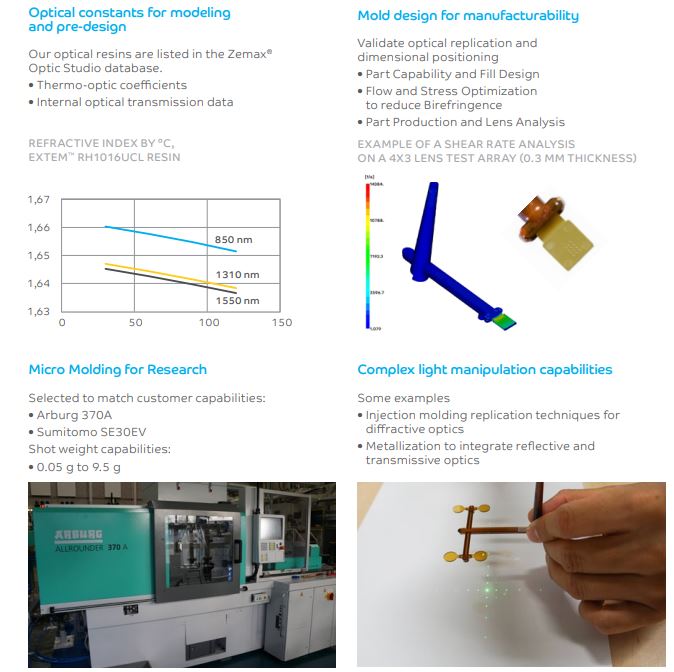

SABIC CAN HELP SUPPORT FROM PART DESIGN TO PRODUCTION

SABIC does not only offer resins but also provides design support and conducts performance testing following industry specific standards.

MATERIAL PROPERTIES

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

DISCLAIMER: ANY SALE BY SABIC, ITS SUBSIDIARIES AND AFFILIATES (EACH A “SELLER”), IS MADE EXCLUSIVELY UNDER SELLER’S STANDARD CONDITIONS OF SALE (AVAILABLE UPON REQUEST) UNLESS AGREED OTHERWISE IN WRITING AND SIGNED ON BEHALF OF THE SELLER. WHILE THE INFORMATION CONTAINED HEREIN IS GIVEN IN GOOD FAITH, SELLER MAKES NO WARRANTY, EXPRESS OR IMPLIED, INCLUDING MERCHANTABILITY AND NONINFRINGEMENT OF INTELLECTUAL PROPERTY, NOR ASSUMES ANY LIABILITY, DIRECT OR INDIRECT, WITH RESPECT TO THE PERFORMANCE, SUITABILITY OR FITNESS FOR INTENDED USE OR PURPOSE OF THESE PRODUCTS IN ANY APPLICATION.

Each customer must determine the suitability of seller materials for the customer’s particular use through appropriate testing and analysis. No statement by seller concerning a possible use of any product, service or design is intended, or should be construed, to grant any license under any patent or other intellectual property right. SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates, unless otherwise noted.

© 2023 Saudi Basic Industries Corporation (SABIC). All Rights Reserved. Any brands, products or services of other companies referenced in this document are the trademarks, service marks and/or trade names of their respective holders.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience