SOLUTIONS FOR AUTOMOTIVE RAIL EXTENSIONS

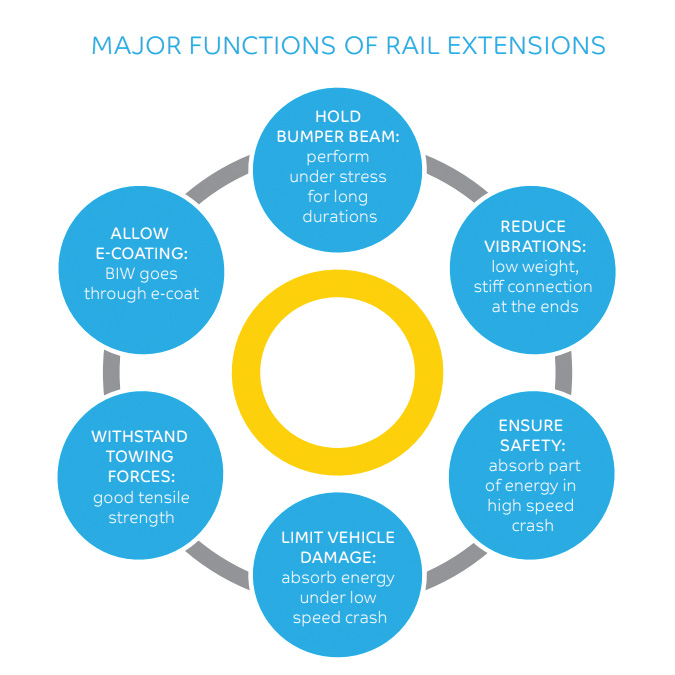

Rail extensions play a crucial role in energy absorption of frontal & rear crashes.

NORYL™ and NORYL GTX™ resins can offer unique solutions to the Automotive industry.

NORYL™ resin is an amorphous blend of polyphenylene ether (PPE) and high impact polystyrene (HIPS). This blend combines the inherent benefits of PPE (robust FR, heat resistance, excellent long-term dimensional stability, low creep, good impact resistance) with the benefits of HIPS (processability and flow).

NORYL GTX™ resin is a semi-crystalline alloy of poly- phenylene ether (PPE) and polyamide (PA). This alloy combines the inherent benefits of PPE (robust FR, heat resistance, excellent long-term dimensional stability, low creep, good impact resistance) with the benefits of PA (chemical and impact resistance and flow).

The result is a chemically resistant material with the stiffness, impact resistance and heat performance required for e-coat and on-line painting. The low density of unfilled NORYL GTX resin can provide part-weight savings of up to 25% over glass or mineral filled resins.

Additionally, NORYL GTX resin may provide sustainability benefits due to its light weight and may be considered for exterior body panels, in-and-on-line painted parts, and EV battery protection.

POTENTIAL BENEFITS OF NORYL GTX RESIN:

Weight reduction up to 60% vs. steel

Ease of assembly

Enhanced front crash performance vs steel

Ability to consolidate multiple rail extension to address IIHS and EURONCAP requirements for SORB and MPDB impacts

VALUE PROPOSITION

• Stiffness, impact + heat performance required for on-line painting

• Class A surface

• Low warpage + long-term dimensional stability

• Low water absorption

• Excellent chemical resistance

• Low density: can provide part-weight savings of up to 25% vs glass or mineral filled resins

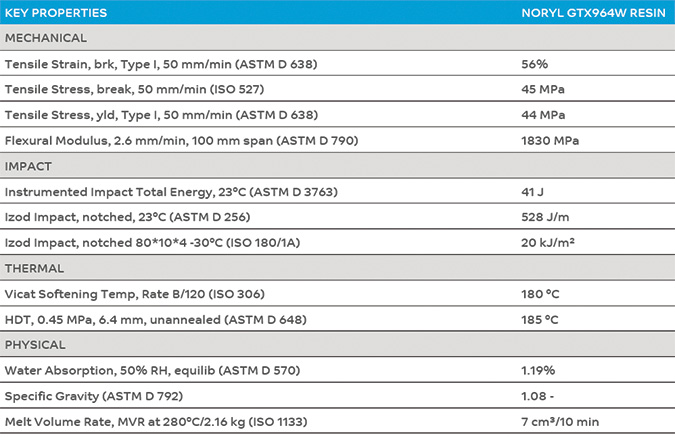

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

DISCLAIMER: ANY SALE BY SABIC, ITS SUBSIDIARIES AND AFFILIATES (EACH A “SELLER”), IS MADE EXCLUSIVELY UNDER SELLER’S STANDARD CONDITIONS OF SALE (AVAILABLE UPON REQUEST) UNLESS AGREED OTHERWISE IN WRITING AND SIGNED ON BEHALF OF THE SELLER. WHILE THE INFORMATION CONTAINED HEREIN IS GIVEN IN GOOD FAITH, SELLER MAKES NO WARRANTY, EXPRESS OR IMPLIED, INCLUDING MERCHANTABILITY AND NONINFRINGEMENT OF INTELLECTUAL PROPERTY, NOR ASSUMES ANY LIABILITY, DIRECT OR INDIRECT, WITH RESPECT TO THE PERFORMANCE, SUITABILITY OR FITNESS FOR INTENDED USE OR PURPOSE OF THESE PRODUCTS IN ANY APPLICATION.

Each customer must determine the suitability of seller materials for the customer’s particular use through appropriate testing and analysis. No statement by seller concerning a possible use of any product, service or design is intended, or should be construed, to grant any license under any patent or other intellectual property right. SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates, unless otherwise noted.

© 2023 Saudi Basic Industries Corporation (SABIC). All Rights Reserved.

Any brands, products or services of other companies referenced in this document are the trademarks, service marks and/or trade names of their respective holders.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience