LNP™ COMPOUNDS WEAR AND FRICTION SOLUTIONS AUTOMOTIVE INTERIORS

The perception of quality in an automotive interior goes beyond how the interior looks and includes how it “feels” and how it “sounds”. Buttons and knobs must not stick and should move smoothly. There should be no harsh or unwanted noise to take away from the driving experience. LUBRICOMP™ and LUBRILOY™ compounds can help contribute to the high quality interior consumers demand.

BUZZ, SQUEAK AND RATTLE

The panels and trim pieces that make up the structure of the vehicles interior are prone to noise generation whenever two parts come in contact with each other. BSR is one of the primary quality issues facing automotive manufactures today. Traditional solutions include adding tape based felt spacers to keep material separated, adding cost and complexity to the build.

INTERNALLY LUBRICATED COMPOUNDS

The addition of an internal lubricant to a thermoplastic material can help reduce the coefficient of friction between two plastic parts, allowing them to slide past each other reducing the vibration that leads to noise. Traditional lubricants like silicone and PTFE are effective, and novel alloy technology can add improved damping characteristic.

AUTOMOTIVE INTERIOR GRADES

Grade | Description | Features | Potential Applications |

| LUBRICOMP NXCY620 | Silicone lubricated PC/ABS | Low COF, dimensional accuracy | Infotainment bezels & trim |

| LUBRILOY D2000 | Alloy lubricated PC | Good wear, low COF, dimensional accuracy, paintable | Glove box guide arms, radio bezel |

| LUBRILOY

R2000AXP | Alloy lubricated

PA 6/6 | Good wear, low COF | Gears, bearings &

door bushings |

| LUBRICOMP ZL003 | 15% PTFE

lubricated PPO | Good wear, low COF, better resistance to acids & bases than PC | Center console slides & rails |

| LUBRILOY

developmental grade | PC/ABS based | Low COF, dimensional accuracy, paintable | Interior panels, frames and trim |

WEAR AND FRICTION SOLUTIONS AUTOMOTIVE INTERIORS

MEASURING PERFORMANCE

Standard wear and friction measurements like thrust washer wear (ASTM D3702) or sliding sled (ASTM 1894) testers can’t always determine if two mating materials will generate noise. Specialized testing for slip- stick characteristics (VDA 230-206) can be a more effective tool for comparison. The wear and friction labs at LNP can leverage multiple characterization tools to aid in application development efforts.

ZIEGLER SSP-04

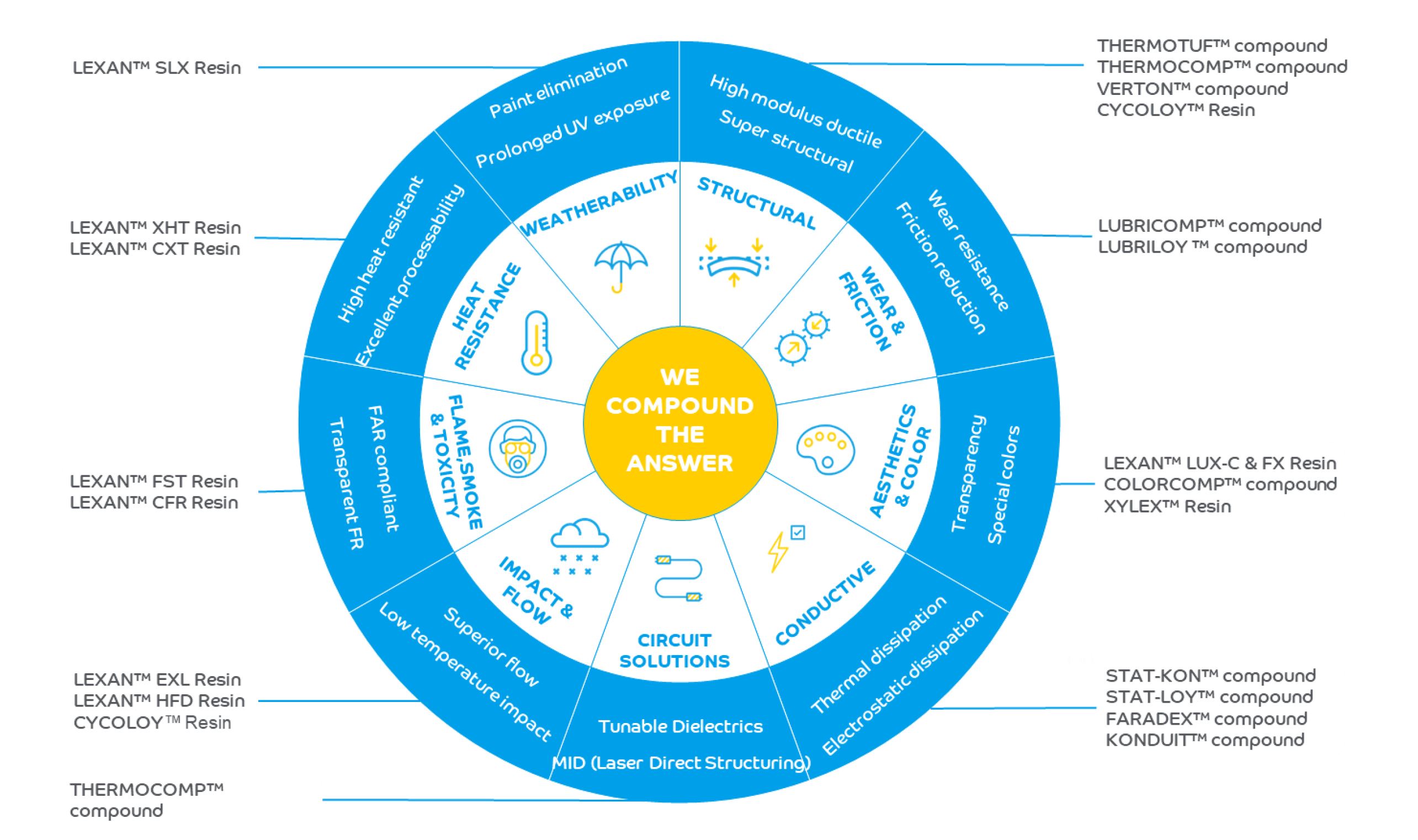

LNP™ COMPOUNDS & LEXAN™ COPOLYMERS SOLUTIONS

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

DISCLAIMER: Any sale by SABIC, its subsidiaries and affiliates (each a “seller”), is made exclusively under seller’s standard conditions of sale (available upon request) unless agreed otherwise in writing and signed on behalf of the seller. While the information contained herein is given in good faith, SELLER MAKES NO WARRANTY, EXPRESS OR IMPLIED, INCLUDING MERCHANTABILITY AND NONINFRINGEMENT OF INTELLECTUAL PROPERTY, NOR ASSUMES ANY LIABILITY, DIRECT OR INDIRECT, WITH RESPECT TO THE PERFORMANCE, SUITABILITY OR FITNESS FOR INTENDED USE OR PURPOSE OF THESE PRODUCTS IN ANY APPLICATION. Each customer must determine the suitability of

seller materials for the customer’s particular use through appropriate testing and analysis. No statement by seller concerning a possible use of any product, service or design is intended, or should be construed, to grant any license under any patent or other intellectual property right. SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates, unless otherwise noted.

© 2023 Saudi Basic Industries Corporation (SABIC). All Rights Reserved.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience