GET MORE FOR YOUR OPTICAL SENSORS WITH EXTEM™ AND ULTEM™ RESINS

WHO IS SABIC’S SPECIALTIES BUSINESS?

Leveraging global application technology centers, we provide innovative material solutions to a wide range of partners in the sensor industry based on our deep materials and processing expertise in engineering thermoplastic resins, compounds, sheet and film, filaments and additives. Together we’re making “Chemistry that Matters™”.

More information on our specialty polymers?

www.sabic.com/en/products/specialties

GET MORE FOR YOUR OPTICAL SENSORS WITH EXTEM™ AND ULTEM™ RESINS

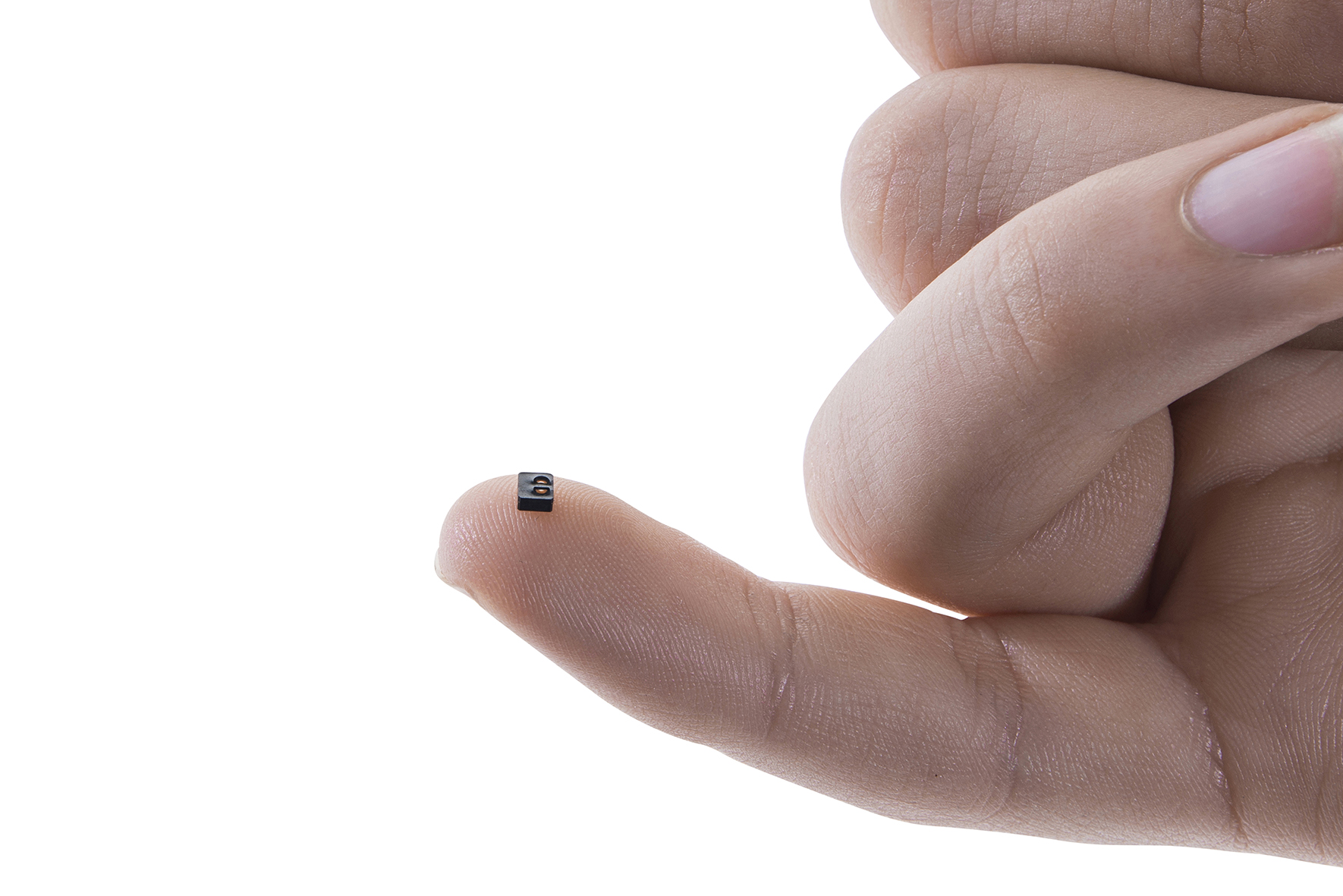

A specialized series of EXTEM and ULTEM resins were developed to be well-suited for IR sensor part design and potentially contribute to lower production cost. These near IR transparent thermoplastics have multiple benefits over glass and thermosets. Compared to other thermoplastics the EXTEM RH resin series has the extraordinary potential to withstand the high temperatures of reflow soldering.

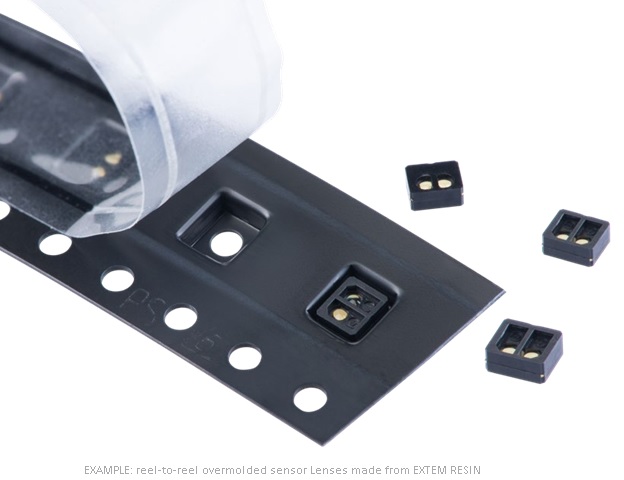

To collimate the light, these resins can be molded into a wide variety of free form optical lens designs. Versus glass, they enable the integration of multiple lenses and other parts, and are easily scalable, with cost-efficient production using multi cavity micro molding.

Easier Design

More complex part designs compared to alternative solutions like glass or thermosets.

Simpler Assembly

Easy integration of mechanical and optical features to simplify design and assembly for potential cost improvement.

Larger Builds

Injection molding of thermoplastics can enable high precision manufacturing of complex parts at very large volumes.

ACHIEVE EXCELLENT LIGHT TRANSMITTANCE FOR YOUR SENSOR LENSES

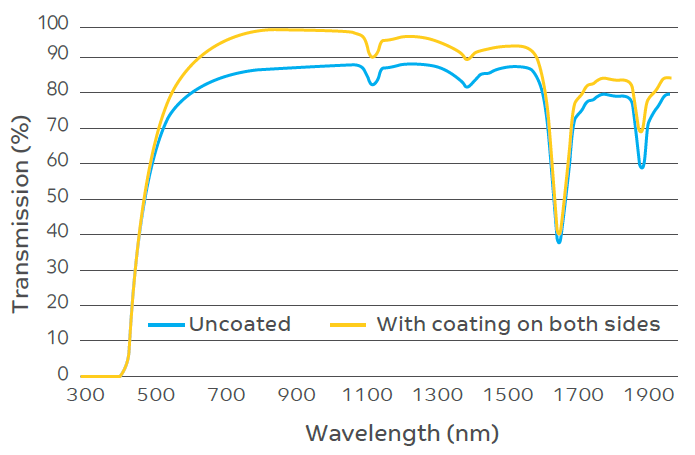

ULTEM™ and EXTEM™ RH resins series show excellent light transmission of over 85% for near infrared optical sensing.

In addition, anti-reflection coatings (ARC) can help reduce first surface reflection losses, improve contrast and boost the transmission to over 95%. This can enable a higher sensitivity for optical sensors or lower signal losses for fiber optical connectors.

EXTEM RH resin SERIES : External transmission (%) at 1 mm, as a function of wavelength, with and without Anti Reflective Coating (ARC)

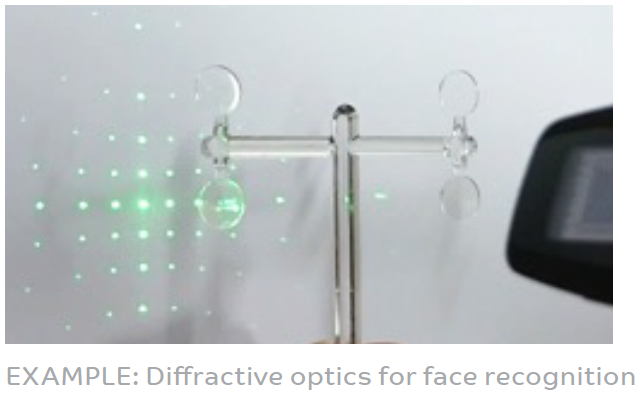

GET DESIGN SUPPORT FOR YOUR REFRACTIVE AND DIFFRACTIVE OPTICS

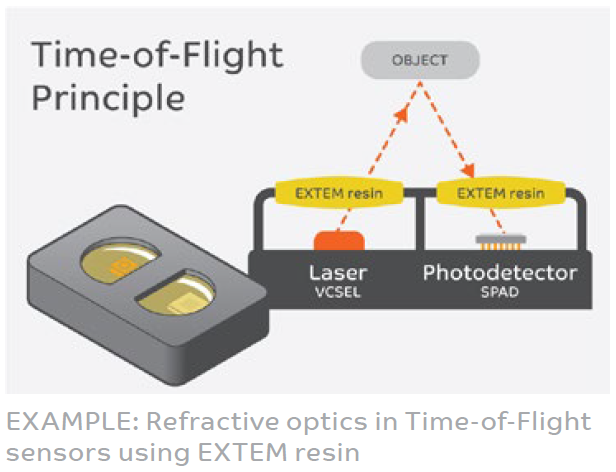

Increased sensor functionality and complexity do require free form optics, for both refractive and diffractive lenses.

SABIC offers injection molding support and can assist with evaluating global micro molders that have proven capabilities to produce ULTEM™ and EXTEM™ resin components.

Validation tools and multipoint datasets are available for reliability testing, simulation and mold flow analysis. Often JEDEC reflow soldering at 260°C is required during the sensor assembly process and EXTEM RH series do offer the unique capability to withstand this high temperature.

ULTEM and EXTEM resins are well-suited for refractive optics

ULTEM and EXTEM resins offer more design freedom than epoxy and typically allow for the elimination of the time-consuming curing step.

Compared to using glass, expensive polish and grinding steps can be avoided. SABIC’s Specialties Business offers support in mold design and processing of our broad portfolio of thermoplastics.

ULTEM and EXTEM resins can be used for diffractive optics

SABIC offers support in various processing technologies for pattern replication, like injection (compression) molding, hot embossing and rapid heat/cool molding. We also offer metrology of surface patterns.

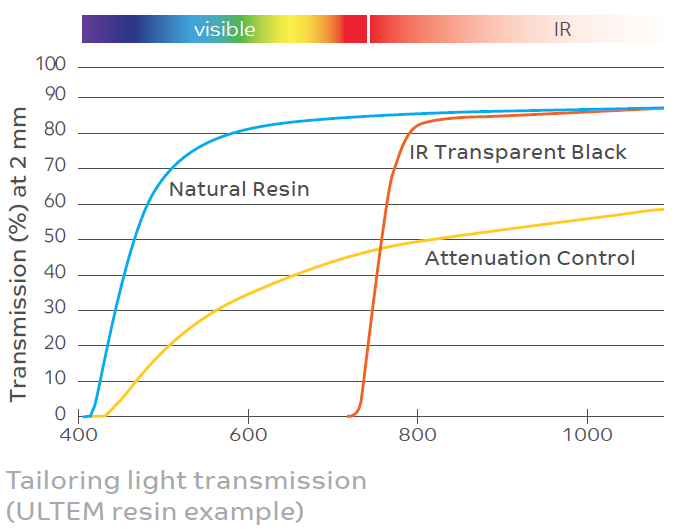

TAILOR LIGHT TRANSMISSION AND CUT OFF WAVELENGTHS

The ability to cut off the transmission of a specific wavelength of light can help reduce stray light and improve the accuracy of the sensor application.

The standard transmission values of ULTEM™ and EXTEM™ resins can be altered through special additives.

For example, transmission can be tailored to a specific value, UV-VIS can be blocked and even full opacification is possible when desired.

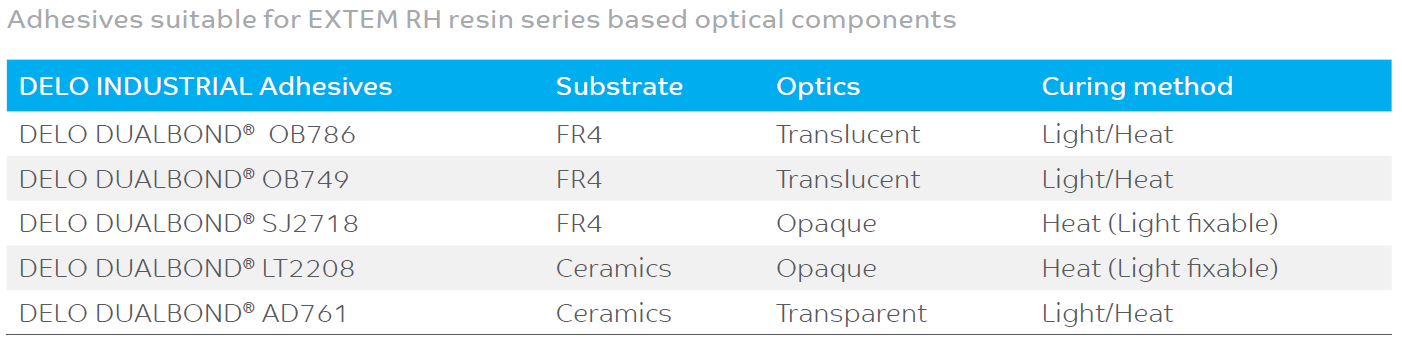

ULTEM and EXTEM RH resins are compatible with all common assembly technologies

SABIC has worked with industrial adhesive suppliers. We can assist in the selection of adhesives with high bonding strength against several substrates.

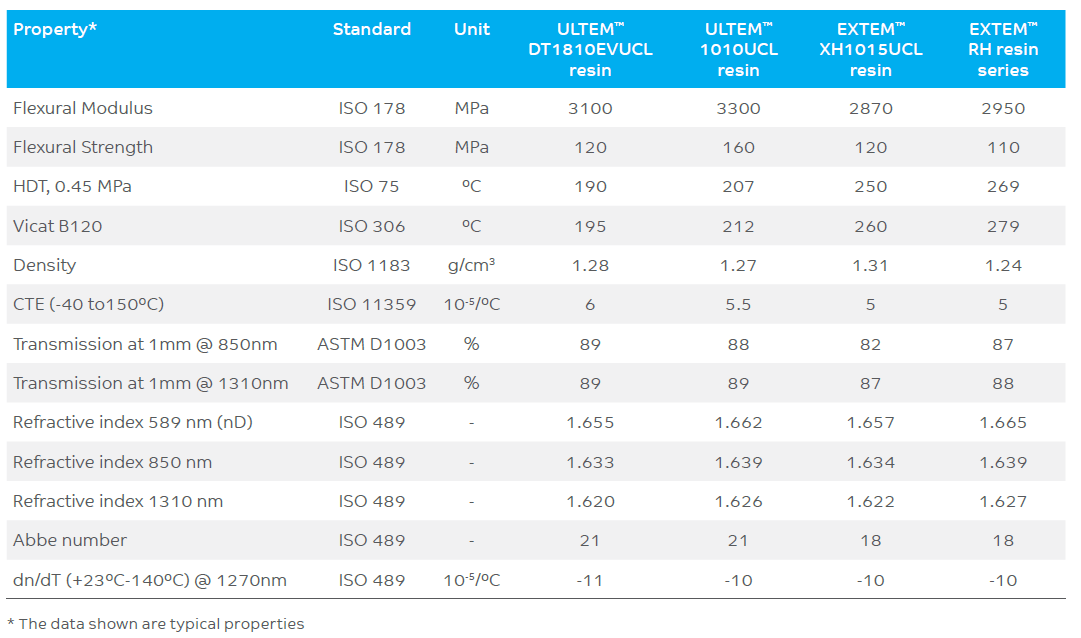

DISCOVER MATERIAL AND OPTICAL PROPERTIES OF OUR SPECIALIZED GRADES FOR POTENTIAL USE IN SENSORS

ZEMAX OPTICSTUDIO® PARAMETERS ARE AVAILABLE FOR DESIGN MODELING

Zemax OpticStudio® parameters for EXTEM RH1016UCL resin

These constants are valid for a temperature range from 30 °C to 120 °C and from 0.5 to 1.7 μm. Dispersion formula returns a valid refractive index between 0.4 and 1.7 μm.

A MEMBER OF

SABIC ISCC+ CERTIFIED RENEWABLE ULTEM RESIN SOLUTIONS

A new portfolio of bio-based ULTEM™ resins that delivers a lower carbon footprint while offering the same high performance and processability as incumbent ULTEM materials is now available.

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

DISCLAIMER: THE MATERIALS, PRODUCTS AND SERVICES OF SAUDI BASIC INDUSTRIES CORPORATION (SABIC) OR ITS SUBSIDIARIES OR AFFILIATES (“SELLER”) ARE SOLD SUBJECT TO SELLER’S STANDARD CONDITIONS OF SALE, WHICH ARE AVAILABLE UPON REQUEST. INFORMATION AND RECOMMENDATIONS CONTAINED IN THIS DOCUMENT ARE GIVEN IN GOOD FAITH. HOWEVER, SELLER MAKES NO EXPRESS OR IMPLIED REPRESENTATION, WARRANTY OR GUARANTEE (i) THAT ANY RESULTS DESCRIBED IN THIS DOCUMENT WILL BE OBTAINED UNDER END-USE CONDITIONS, OR (ii) AS TO THE EFFECTIVENESS OR SAFETY OF ANY DESIGN OR APPLICATION INCORPORATING SELLER’S MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS. UNLESS OTHERWISE PROVIDED IN SELLER’S STANDARD CONDITIONS OF SALE, SELLER SHALL NOT BE RESPONSIBLE FOR ANY LOSS RESULTING FROM ANY USE OF ITS MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS DESCRIBED IN THIS DOCUMENT.

Each user is responsible for making its own determination as to the suitability of Seller’s materials, products, services or recommendations for the user’s particular use through appropriate end-use and other testing and analysis. Nothing in any document or oral statement shall be deemed to alter or waive any provision of Seller’s Standard Conditions of Sale or this Disclaimer, unless it is specifically agreed to in a writing signed by Seller. Statements by Seller concerning a possible use of any material, product, service or design do not, are not intended to, and should not be construed to grant any license under any patent or other intellectual property right of Seller or as a recommendation for the use of any material, product, service or design in a manner that infringes any patent or other intellectual property right.

SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates, unless otherwise noted.

© 2023 Saudi Basic Industries Corporation (SABIC). All Rights Reserved. Any brands, products or services of other companies referenced in this document are the trademarks, service marks and/or trade names of their respective holders.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience