LNP™ COMPOUNDS - CONDUCTIVE SOLUTIONS CARRIER TAPE– SEMICONDUCTOR APPLICATIONS

There are various types of automated packaging and transportation methods for IC chips and micro parts. Carrier tape is used for transporting electronic components from such manufacturers to end-users for automated assembly. In order to mount a large number of parts in a small space, it is necessary to supply many types of parts in a compact manner. LNP™ STAT-KONTM compounds are typically used by our customers to meet the needs for protecting electronic components from undesirable electro-static effects and this material typically exhibits good process-ability of the carrier tape.

REQUIREMENTS OF CARRIER TAPES

The following are typical benefits of LNP™ STAT- KONTM compounds and therefore these compounds may be an excellent candidate for Carrier Tapes:

• Excellent visual quality

• Integrity during high speed processing

• Adhesion to cover tapes

• Conductive post forming

• Dimensional stability, low shrink

• Wide processing window

• Electrical conductivity

ELECTRICALLY CONDUCTIVE COMPOUNDS

The addition of electrically conductive fillers to thermoplastic resins may typically increase the electrical conductivity, thereby aimed to reduce the risks for electrostatic charging and discharging. Traditional conductive fillers like Carbon Powder and Carbon Fibers are common and effective. Carbon powder may impart dimensional stability and warpage control on the parts whilst Carbon Fibers may typically enhance certain mechanical properties such as strength and modulus.

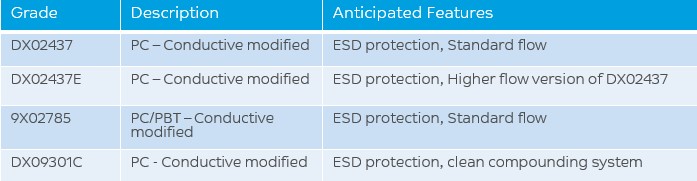

CONDUCTIVE GRADES FOR THE CARRIER TAPE- SEMICONDUCTOR APPLICATIONS

CLEAN COMPOUND POLICY

Clean compound system (CCS) materials feature low levels (ppb) of volatiles and ionic contamination from nitrates, chlorides and sulfates. They are typically used for components and handling devices in mass storage, disk drive, tape drive and optical/DVD applications. These grades can be very application specific.

KEY BENEFITS OF CLEAN COMPOUND SYSTEM (CCS) MATERIALS:

• Aimed to reduce the potential for wafer damage

• May promote more accurate and reliable data reading

• Possibly extends product longevity

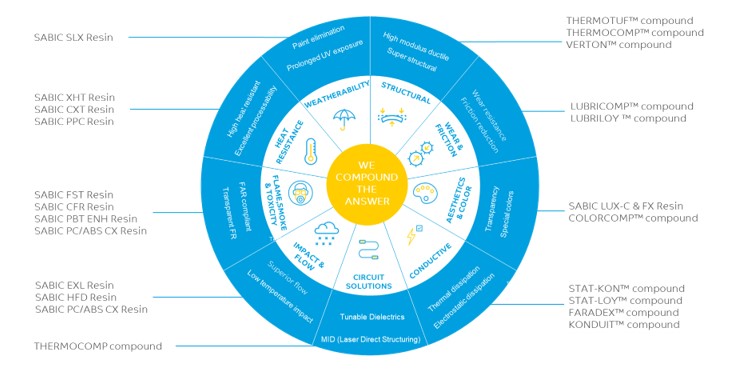

LNP™ COMPOUNDS & SABIC COPOLYMER SOLUTIONS

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

DISCLAIMER: Any sale by SABIC, its subsidiaries and affiliates (each a “seller”), is made exclusively under seller’s standard conditions of sale (available upon request) unless agreed otherwise in writing and signed on behalf of the seller. While the information contained herein is given in good faith, SELLER MAKES NO WARRANTY, EXPRESS OR IMPLIED, INCLUDING MERCHANTABILITY AND NONINFRINGEMENT OF INTELLECTUAL PROPERTY, NOR ASSUMES ANY LIABILITY, DIRECT OR INDIRECT, WITH RESPECT TO THE PERFORMANCE, SUITABILITY OR FITNESS FOR INTENDED USE OR PURPOSE OF THESE PRODUCTS IN ANY APPLICATION. Each customer must determine the suitability of

seller materials for the customer’s particular use through appropriate testing and analysis. No statement by seller concerning a possible use of any product, service or design is intended, or should be construed, to grant any license under any patent or other intellectual property right. SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates, unless otherwise noted.

© 2023 Saudi Basic Industries Corporation (SABIC). All Rights Reserved.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience