MEDICAL DEVICES - LNP™ COMPOUNDS: WEAR AND FRICTION SOLUTIONS

WEAR AND FRICTION SOLUTIONS FOR POTENTIAL USE IN MEDICAL DEVICES

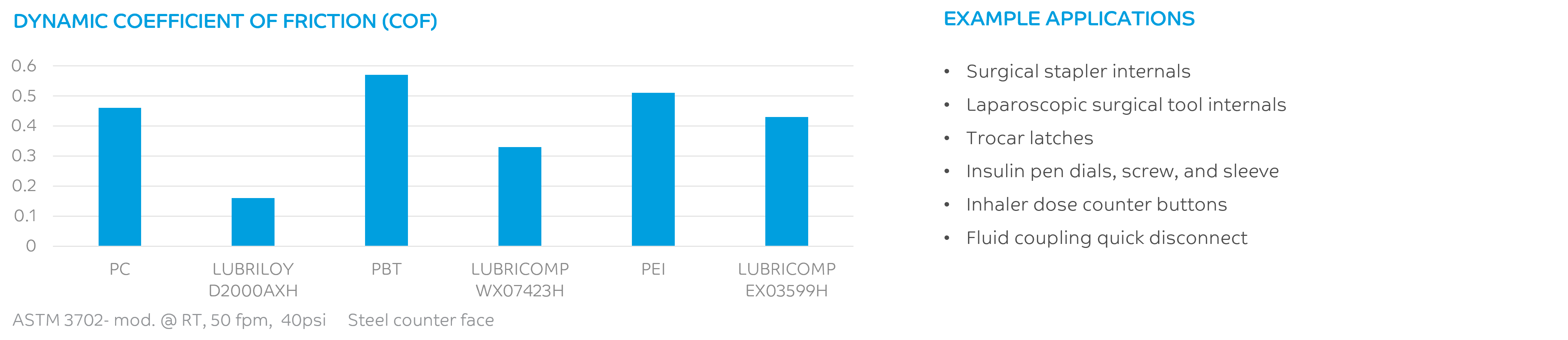

For a medical device, whether it be a drug delivery pen or a laparoscopic surgical tool, repeatable and efficient motion is critical to performance. The friction between moving parts plays a large role in how a device is perceived and accepted by both consumers and healthcare professionals. LUBRICOMP and LUBRILOY compounds can help deliver the performance required.Some healthcare applications where resistance to wear and friction may be required include surgical stapler internals; laparoscopic surgical tool internals; trocar latches; insulin pen dials, screws, and sleeves; inhaler dose counter buttons; fluid coupling quick disconnects.

GROWING LIST OF DEMANDS

The demands on wear and friction materials for medical devices grow as sterilization and cleaning techniques evolve, parts get smaller and thinner, and market trends move towards more consumer-friendly styling and colors. Add the heightened emphasis on system cost optimization and the need for innovative internally lubricated thermoplastic solutions expands.

INTERNALLY LUBRICATED COMPOUNDS

The addition of an internal lubricant to a thermoplastic material can reduce the coefficient of friction between two plastic parts, allowing them to slide past each other smoothly with minimal wear. Traditional lubricants like medical grade silicone and PTFE can be combined with advanced PC copolymer technology to deliver the required performance in thin wall parts.

LUBRICATED COMPOUNDS IN HEALTHCARE APPLICATIONS

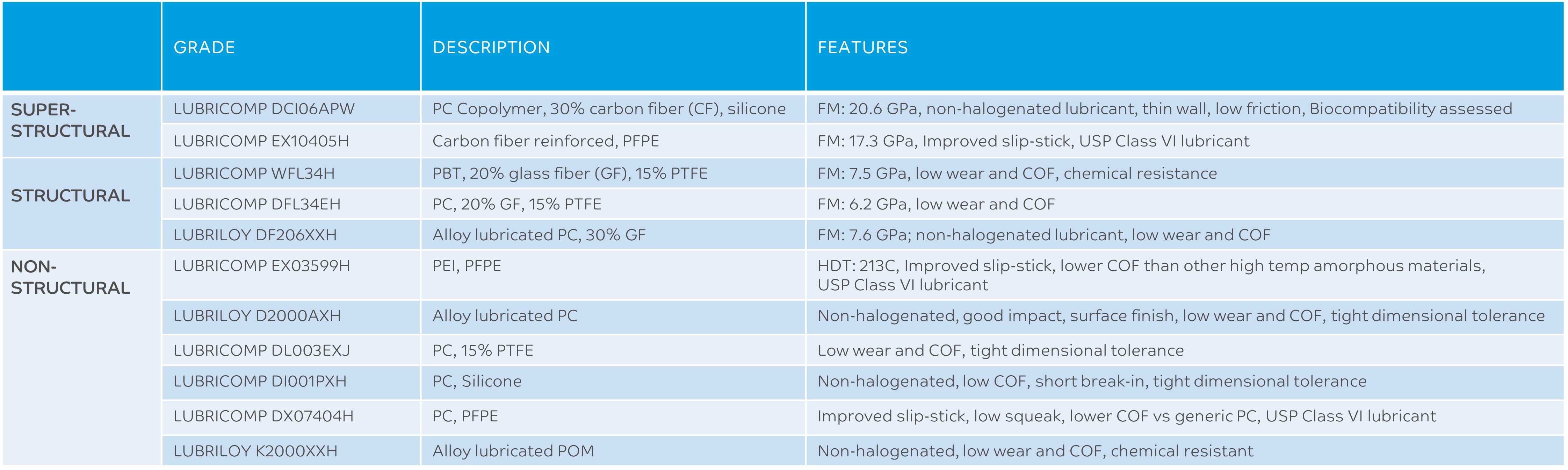

Below find a selection of LUBRICOMP and LUBRILOY compound grades, descriptions, and key features categorized by Super Structural, Structural, and Non-structural applications.

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

DISCLAIMER: ANY SALE BY SABIC, ITS SUBSIDIARIES AND AFFILIATES (EACH A “SELLER”), IS MADE EXCLUSIVELY UNDER SELLER’S STANDARD CONDITIONS OF SALE (AVAILABLE UPON REQUEST) UNLESS AGREED OTHERWISE IN WRITING AND SIGNED ON BEHALF OF THE SELLER. WHILE THE INFORMATION CONTAINED HEREIN IS GIVEN IN GOOD FAITH, SELLER MAKES NO WARRANTY, EXPRESS OR IMPLIED, INCLUDING MERCHANTABILITY AND NONINFRINGEMENT OF INTELLECTUAL PROPERTY, NOR ASSUMES ANY LIABILITY, DIRECT OR INDIRECT, WITH RESPECT TO THE PERFORMANCE, SUITABILITY OR FITNESS FOR INTENDED USE OR PURPOSE OF THESE PRODUCTS IN ANY APPLICATION.

Each customer must determine the suitability of seller materials for the customer’s particular use through appropriate testing and analysis. No statement by seller concerning a possible use of any product, service or design is intended, or should be construed, to grant any license under any patent or other intellectual property right. SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates, unless otherwise noted.

© 2024 Saudi Basic Industries Corporation (SABIC). All Rights Reserved.

Any brands, products or services of other companies referenced in this document are the trademarks, service marks and/or trade names of their respective holders.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience