LNPTM COMPOUNDS WEAR AND FRICTION SOLUTIONS THERMOPLASTIC GEARING

LNPTM COMPOUNDS

WEAR AND FRICTION SOLUTIONS

THERMOPLASTIC GEARING

At the push of a button, windows move, doors lock, copies get made, and HVAC comes to life. These electromotive actions require gears, bearings, bushings and other wear surfaces to provide smooth, reliable, actuation forces. LUBRICOMPTM and LUBRILOYTM compounds can help deliver the high quality performance required.

THERMOPLASTIC GEARING

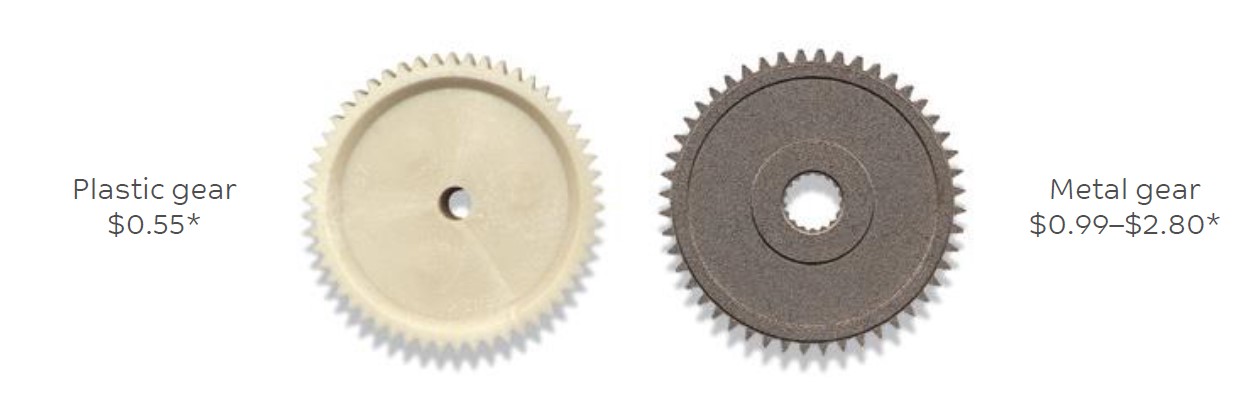

Injection molded thermoplastic gears can

replace die cast, machined and sintered metal

gears in a variety of applications. They are

attractive to part designers not only because of

their low weight and design flexibility, but

because they generally cost less to manufacture

in mid to high volume applications.

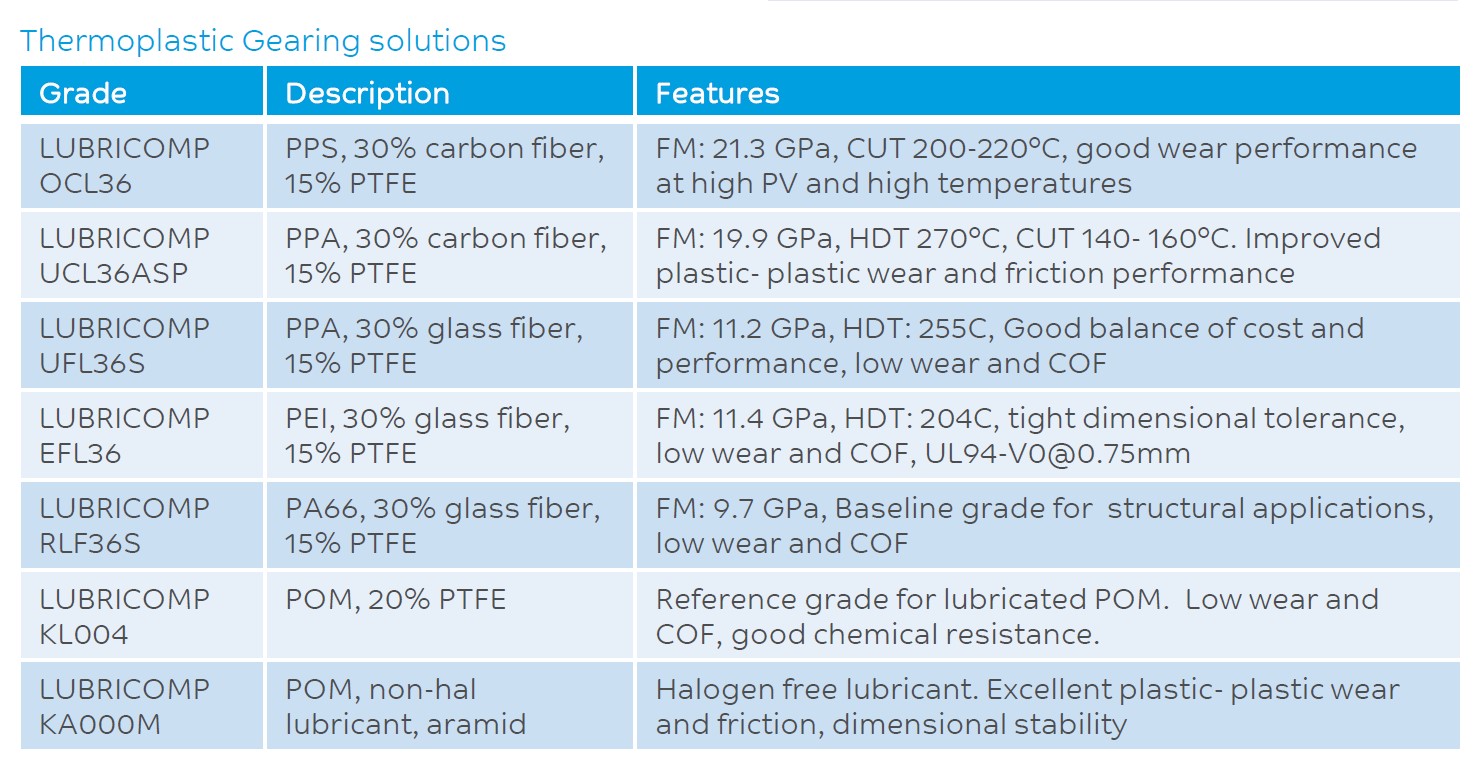

INTERNALLY LUBRICATED COMPOUNDS

The addition of an internal lubricant to a

thermoplastic can improve the wear resistance

and reduce friction in plastic parts. Traditional

lubricants like PTFE and PTFE/Si blends are

common, with reinforcements like glass and

carbon fiber adding strength and modulus. The

use of high temperature resins like PEEK, PPS

and PPA can give performance at elevated

temperatures.

SAVE UP TO 80%

* Typical price comparison for plastic vs. metal gears: Sintered metal gear cost $2.33 powder metal $1.10 + sintering $1.00 + secondary operations $0.23 or machined metal gear $2.80 metal blank $0.60 + machining $2.20 vs. plastic gear $0.55 resin $0.25 + injection molding $0.30. Prices may be subject to change.

WEAR AND FRICTION SOLUTIONS

THERMOPLASTIC GEARING

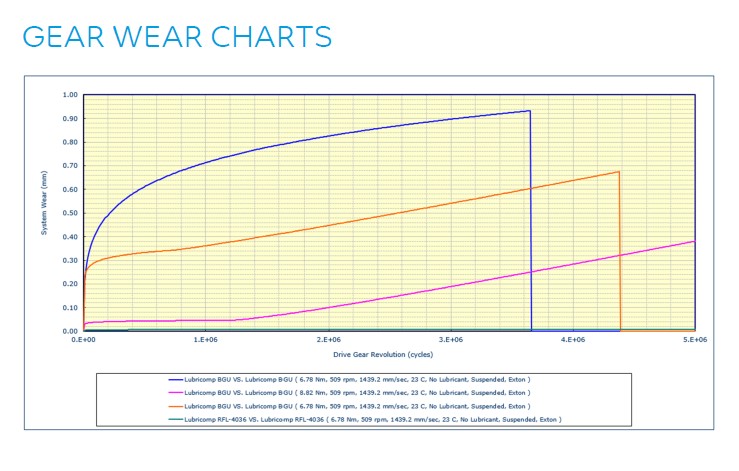

When selecting materials for gear applications,

data sheets reporting attributes tested to ASTM

or ISO standards help by providing single-point

data like tensile strength, flexural modulus and

impact strength. But single-point data are often

insufficient for gear designs because the

physical and mechanical properties of

thermoplastics vary with temperature and

environmental changes.

Multivariate data is needed to effectively

compare materials, evaluate performance in

specific application, and select the best material

for the product. To meet this need, LNP has

developed an extensive database of multi-variate

data on its specialty compounds for gear

applications. This information compliments

single-point data and includes actual gear-on-

gear wear testing.

MULTIVARITE DATA

•Tensile Stress-strain

•Tensile Fatigue

•Tensile Creep

• Low Shear Viscosity (DMA)

•Coef. Of Thermal Expansion

•PVT

•High Shear Viscosity

•Specific Heat

•Thermal Conductivity

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

Any sale by SABIC, its subsidiaries and affiliates (each a "seller"), is made exclusively under seller's standard conditions of sale (available upon request) unless agreed otherwise in writing and signed on behalf of the seller. While the information contained herein is given in good faith, SELLER MAKES NO WARRANTY, EXPRESS OR IMPLIED, INCLUDING MERCHANTABILITY AND NONINFRINGEMENT OF INTELLECTUAL PROPERTY, NOR ASSUMES ANY LIABILITY, DIRECT OR INDIRECT, WITH RESPECT TO THE PERFORMANCE, suitably OR FITNESS FOR INTENDED USE OR PURPOSE OF THESE PRODUCTS IN ANY APPLICATION. Each customer must determine the suitability of seller materials for the customer's particular use through appropriate testing and analysis. No statement by seller concerning a possible use of any product, service or design is intended, or should be construed, to grant any license under any patentor other intellectual property right. SABIC and brands marked with TM are trademarks of SABIC or its subsidiaries or affiliates, unless otherwise noted.

@ 2023 Saudi Basic Industries Corporation (SABIC). All Rights Reserved.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience