High performance compounds for structural healthcare applications

…PROVIDE AN OPPORTUNITY TO SOLVE TOUGH DESIGN PROBLEMS

Among the family of high performance engineered thermoplastic compounds offered by SABIC to help healthcare device manufacturers meet these challenges are two new, high modulus carbon fiber reinforced solutions.

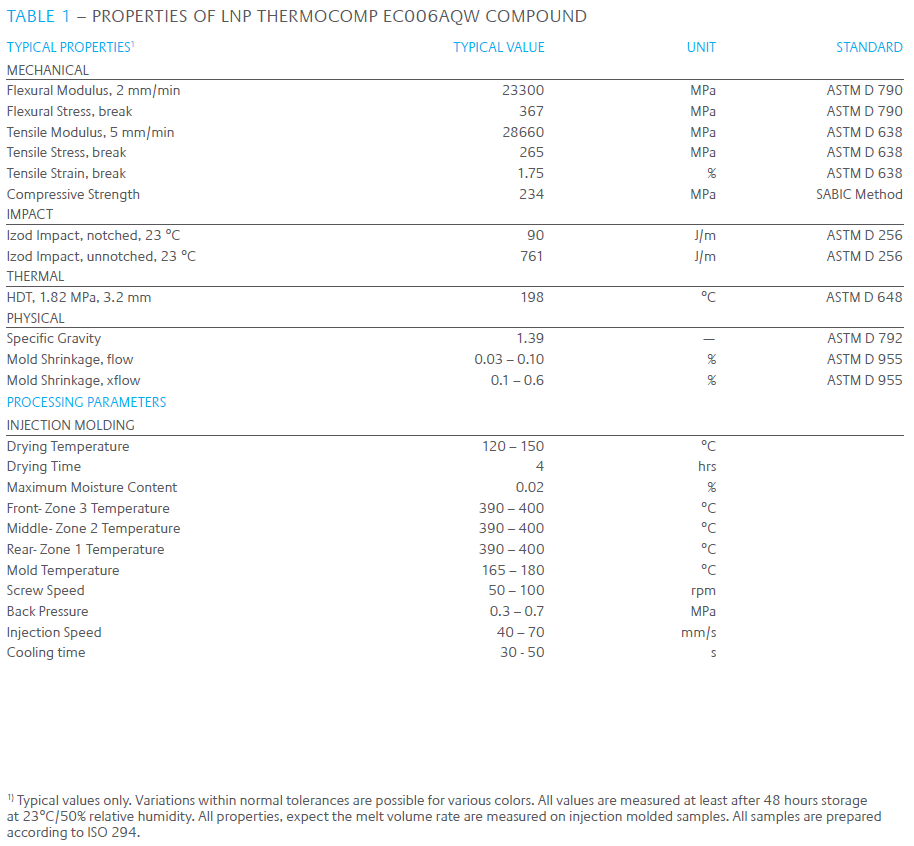

LNP THERMOCOMP EC006AQW compound

LNP THERMOCOMP EC006AQW compound is a high modulus carbon fiber reinforced PEI resin, an excellent candidate material for demanding applications which require high strength and stiffness, excellent chemical compatibility and mechanical stability in repeated, harsh sterilization environments. Potential applications may include either disposable or re-usable surgical instruments, fixation devices, patient transport devices, medical device housings and other components and hardware where metals have been used.

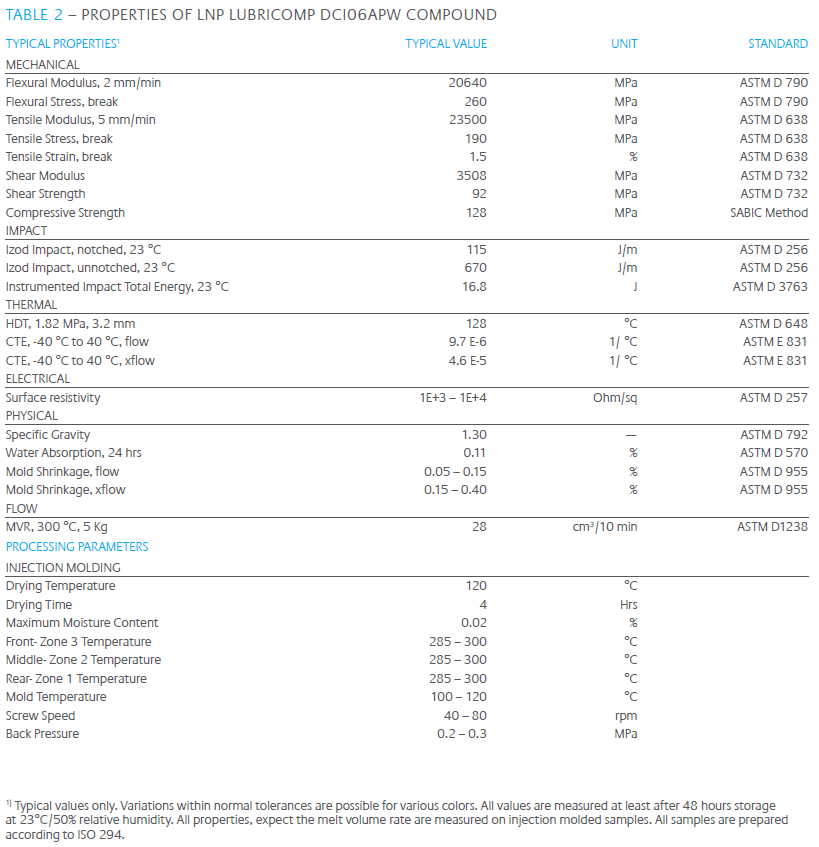

LNP LUBRICOMP DCI06APW compound

LNP LUBRICOMP DCI06APW compound combines the benefits of high modulus carbon fiber with a unique high flow, ductile polycarbonate for demanding applications which require high strength and stiffness, internal lubrication and good processability, enabling a balance between design flexibility and manufacturability in disposable medical devices. Potential applications may include disposable surgical instruments, medical device housings and other components where the use of metals or other stiff thermoplastics with poor flow can create design and manufacturing challenges.

PRODUCT SELECTION

IMPROVED PERFORMANCE OF SABIC’s CARBON FIBER REINFORCED LNP THERMOCOMP and LUBRICOMP Compounds

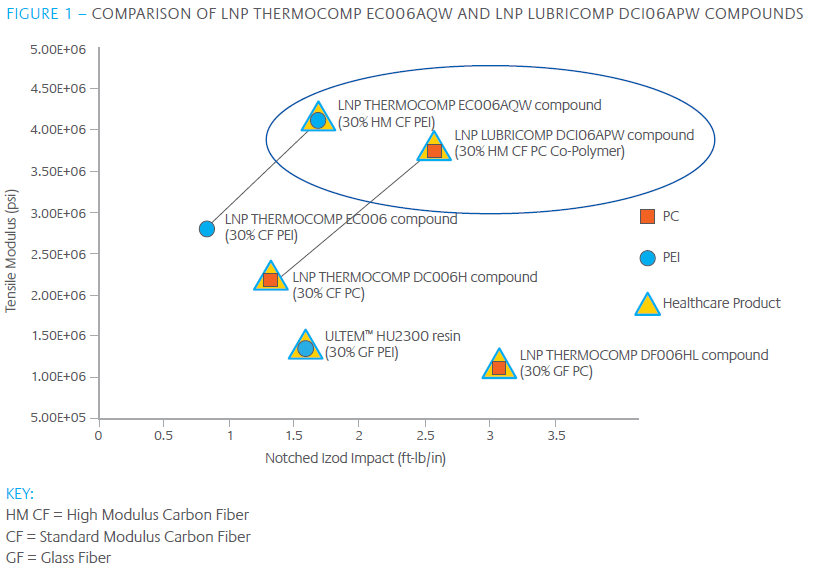

Both LNP THERMOCOMP EC006AQW and LNP LUBRICOMP DCI06APW compounds represent a significant increase in both tensile modulus and impact strength versus standard carbon fiber and glass reinforced thermoplastics as shown in Figure 1.

IMPLANT POLICY

SABIC does not knowingly support or provide resin for applications that remain implanted beyond 29 days.

RESIN BIOCOMPATIBILITY

LNP LUBRICOMP DCI06APW compound and LNP THERMOCOMP EC006AQW compound have been pre-assessed and passed the material related tests from the ISO 10993 “Biological Evaluation of Medical Devices”. SABIC does not knowingly support the use of grades not designated as “biocompatible” in healthcare applications requiring biocompatibility.

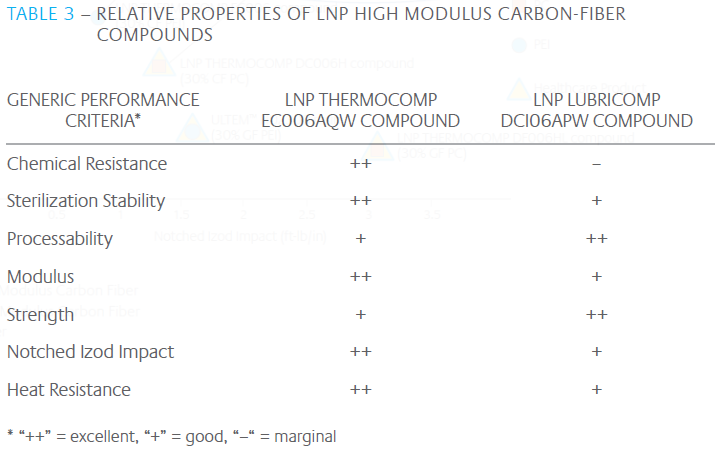

While these two new LNP compounds both demonstrate significant increases in strength and stiffness than existing fiber-filled compounds, it is important to consider the broad set of application requirements when choosing a material. Table 3 provides a qualitative comparison of several other key criteria which may be factors to consider in material selection.

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

DISCLAIMER: THE MATERIALS, PRODUCTS AND SERVICES OF SAUDI BASIC INDUSTRIES CORPORATION (SABIC) OR ITS SUBSIDIARIES OR AFFILIATES (“SELLER”) ARE SOLD SUBJECT TO SELLER’S STANDARD CONDITIONS OF SALE, WHICH ARE AVAILABLE UPON REQUEST. INFORMATION AND RECOMMENDATIONS CONTAINED IN THIS DOCUMENT ARE GIVEN IN GOOD FAITH. HOWEVER, SELLER MAKES NO EXPRESS OR IMPLIED REPRESENTATION, WARRANTY OR GUARANTEE (i) THAT ANY RESULTS DESCRIBED IN THIS DOCUMENT WILL BE OBTAINED UNDER END-USE CONDITIONS, OR (ii) AS TO THE EFFECTIVENESS OR SAFETY OF ANY DESIGN OR APPLICATION INCORPORATING SELLER’S MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS. UNLESS OTHERWISE PROVIDED IN SELLER’S STANDARD CONDITIONS OF SALE, SELLER SHALL NOT BE RESPONSIBLE FOR ANY LOSS RESULTING FROM ANY USE OF ITS MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS DESCRIBED IN THIS DOCUMENT. Each user is responsible for making its own determination as to the suitability of Seller’s materials, products, services or recommendations for the user’s particular use through appropriate end-use and other testing and analysis. Nothing in any document or oral statement shall be deemed to alter or waive any provision of Seller’s Standard Conditions of Sale or this Disclaimer, unless it is specifically agreed to in a writing signed by Seller. Statements by Seller concerning a possible use of any material, product, service or design do not, are not intended to, and should not be construed to grant any license under any patent or other intellectual property right of Seller or as a recommendation for the use of any material, product, service or design in a manner that infringes any patent or other intellectual property right.

SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates.

© 2023 Copyright SABIC. All rights reserved.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience