LNP™ COMPOUNDS - INTRODUCTION TO HIGH FLOW DUCTILE (HFD) RESINS

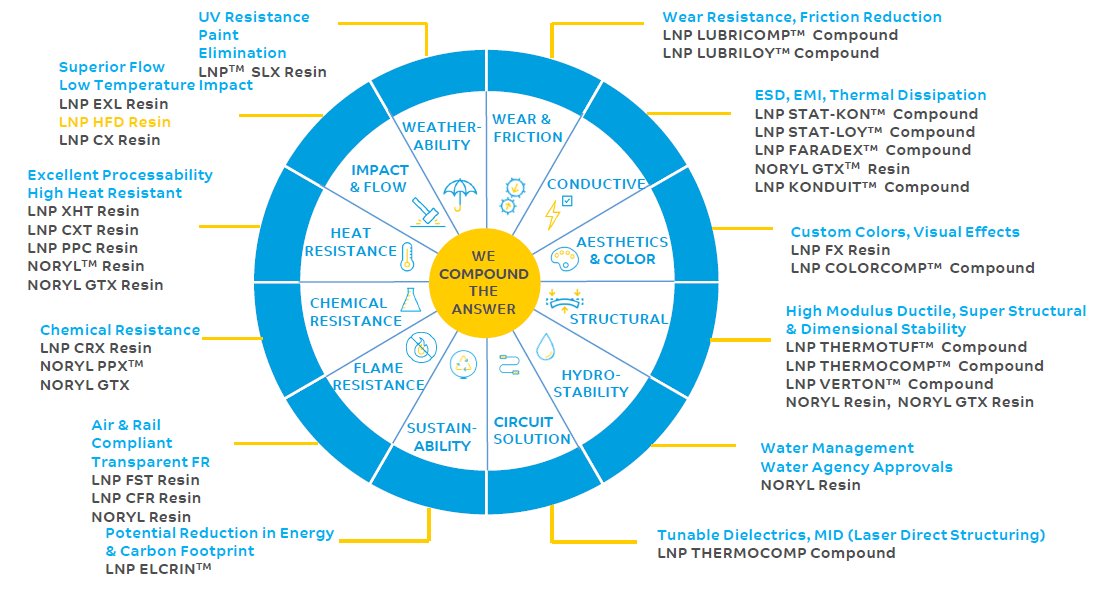

LNP™ RESINS AND COMPOUNDS

LNP™ COPOLYMER RESINS SUMMARY

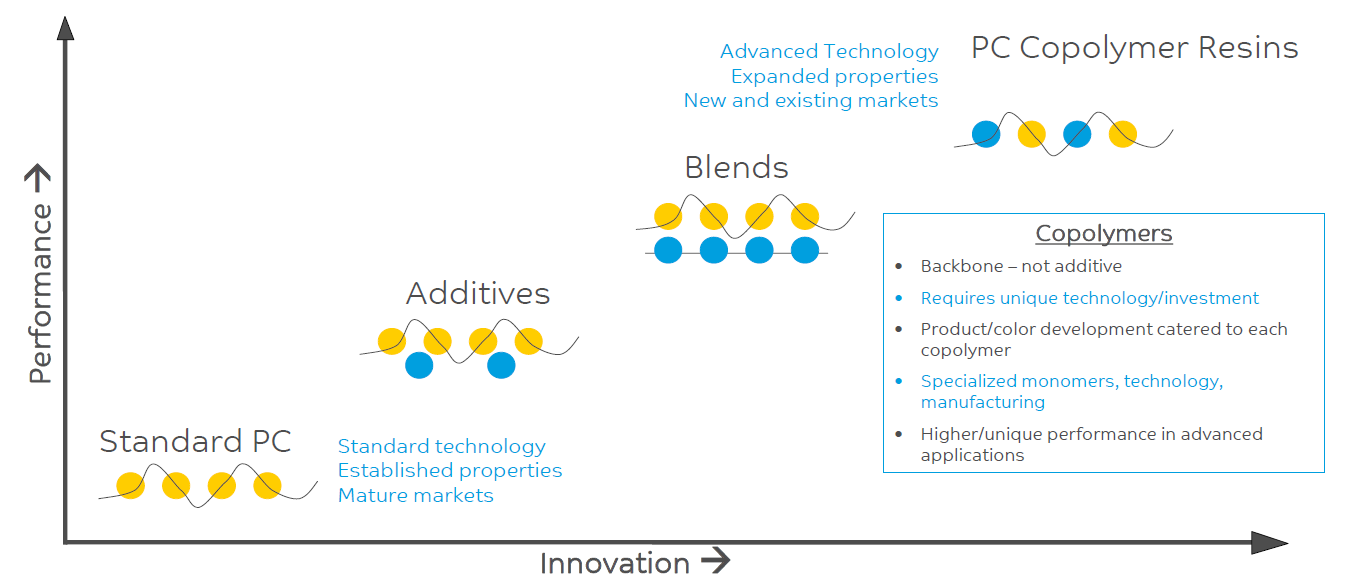

WHAT ARE PC COPOLYMERS?

HFD RESIN - HIGH FLOW DUCTILE

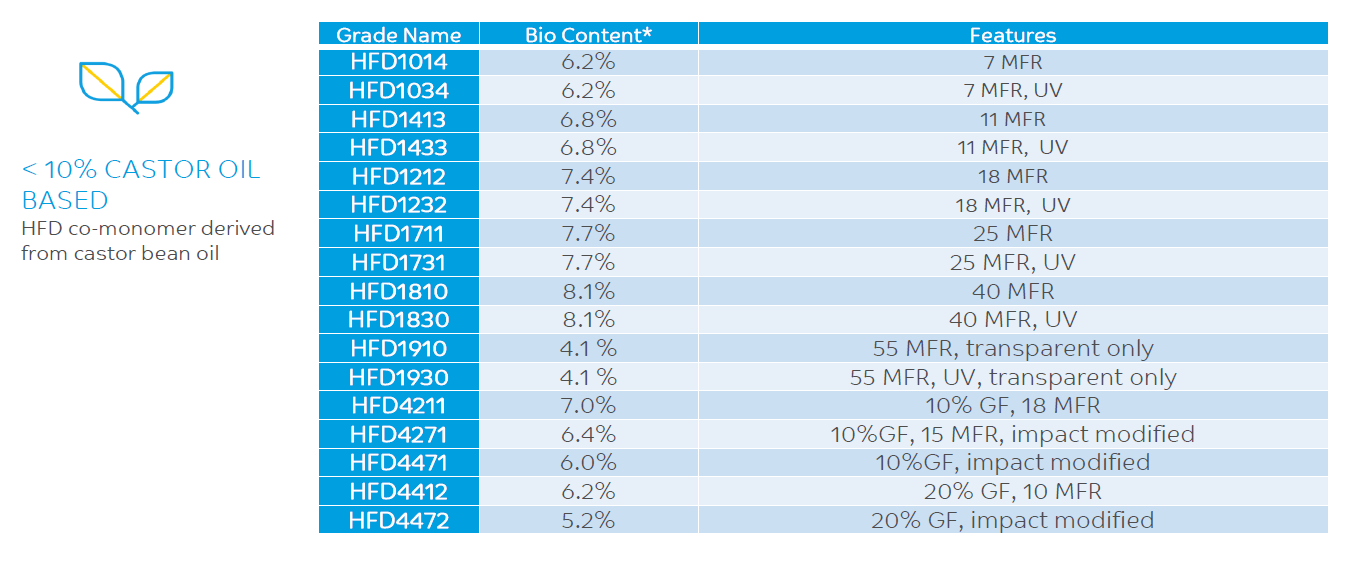

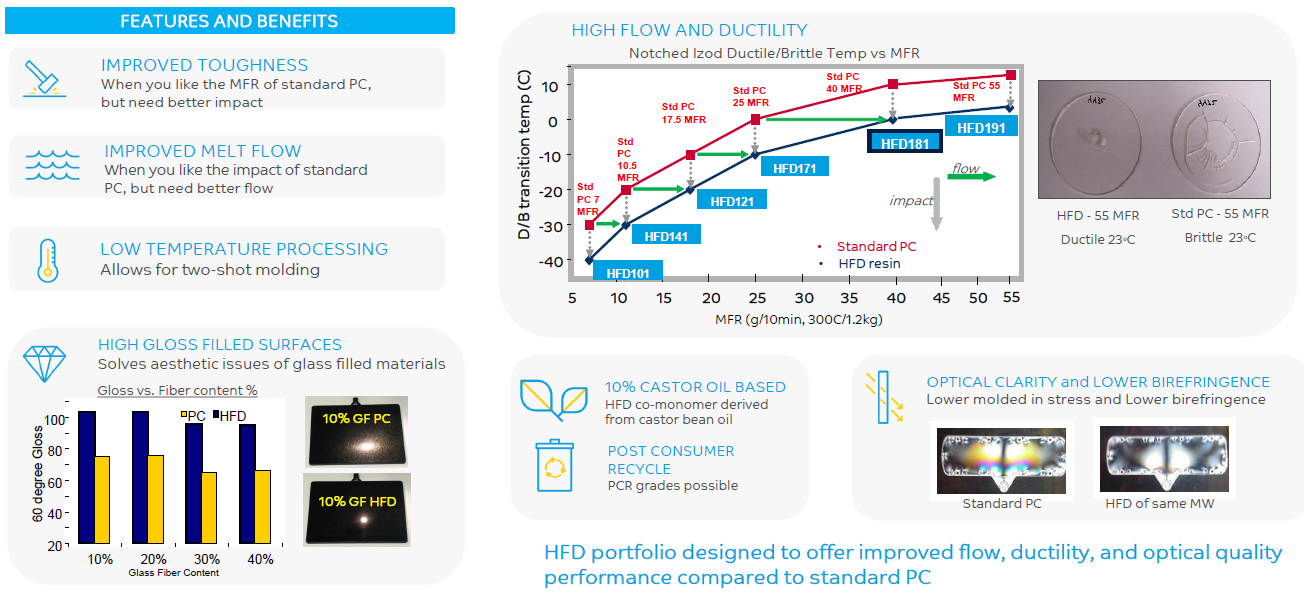

• HFD co-monomer derived from castor bean oil (<10% bio-sourced content)

• Superior flow (up to 30-40% higher vs. PC) while maintaining ductility and toughness.

• Reduced mold-in-stress to avoid birefringence

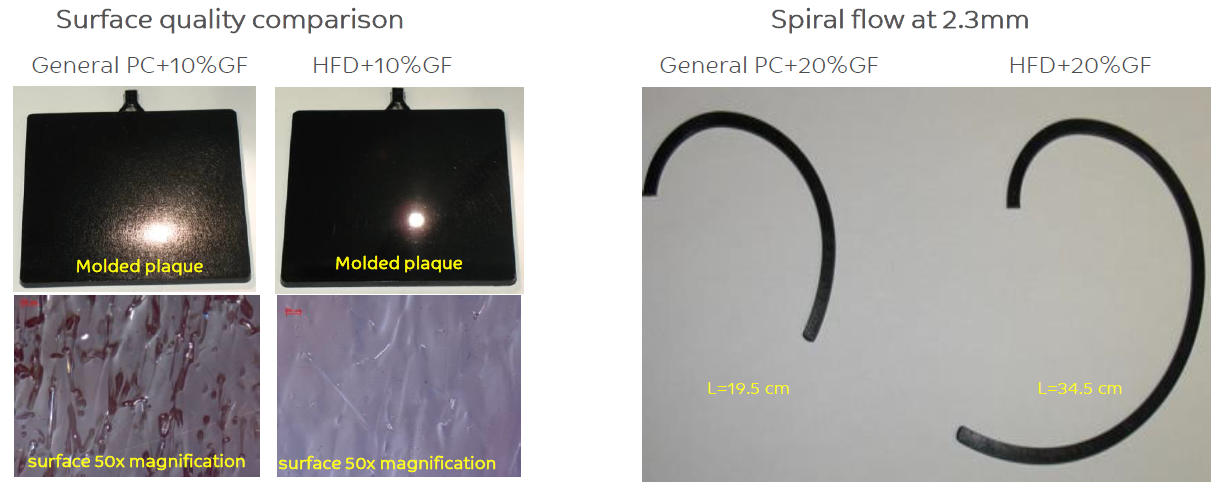

• Higher flow solves aesthetic issues typical of glass filled materials

• Faster processing and cycle time reduction

• 20° C lower processing temperature vs. standard PC for two shot molding

HFD RESIN

HFD RESIN

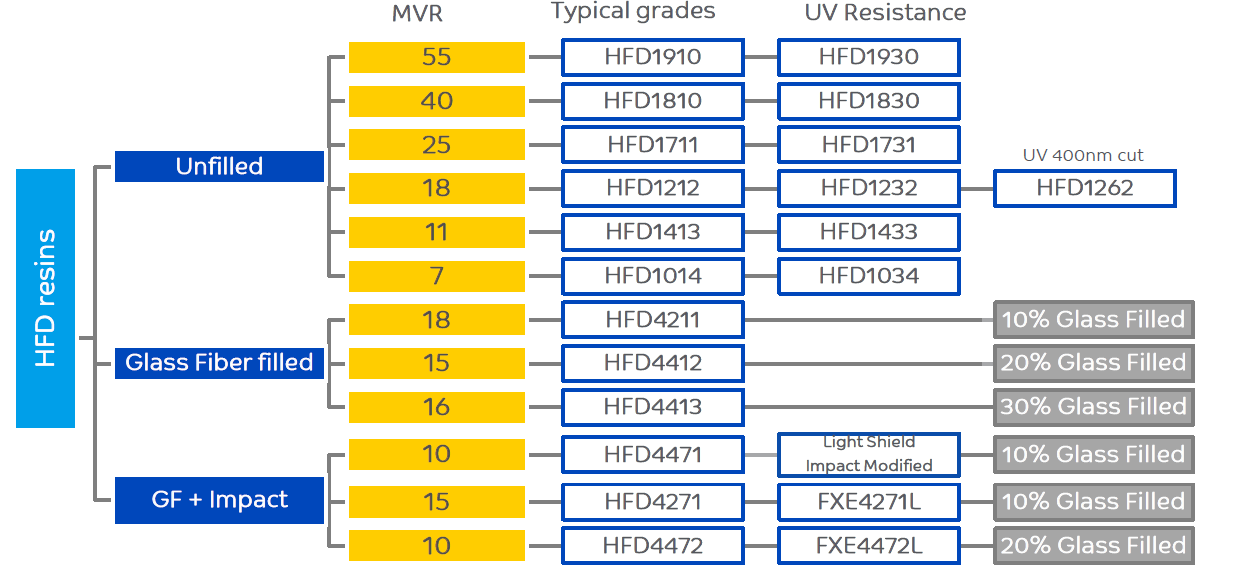

HFD PORTFOLIO

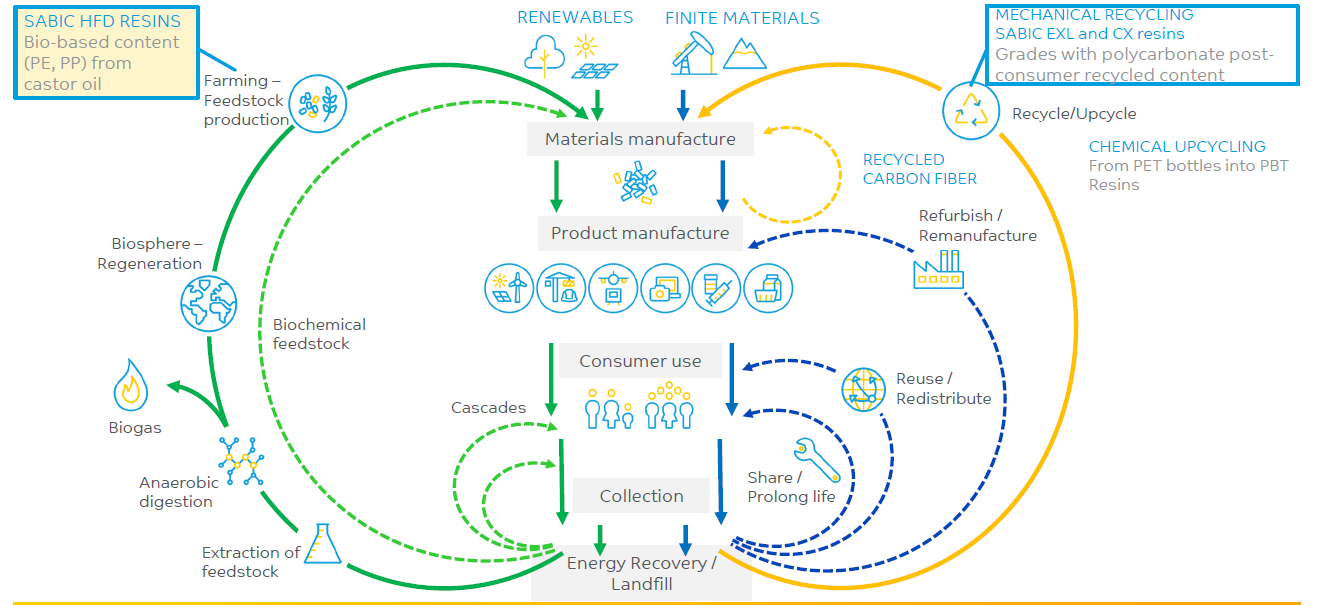

SOLUTIONS FOR CIRCULAR ECONOMY

HFD PORTFOLIO BIO CONTENT

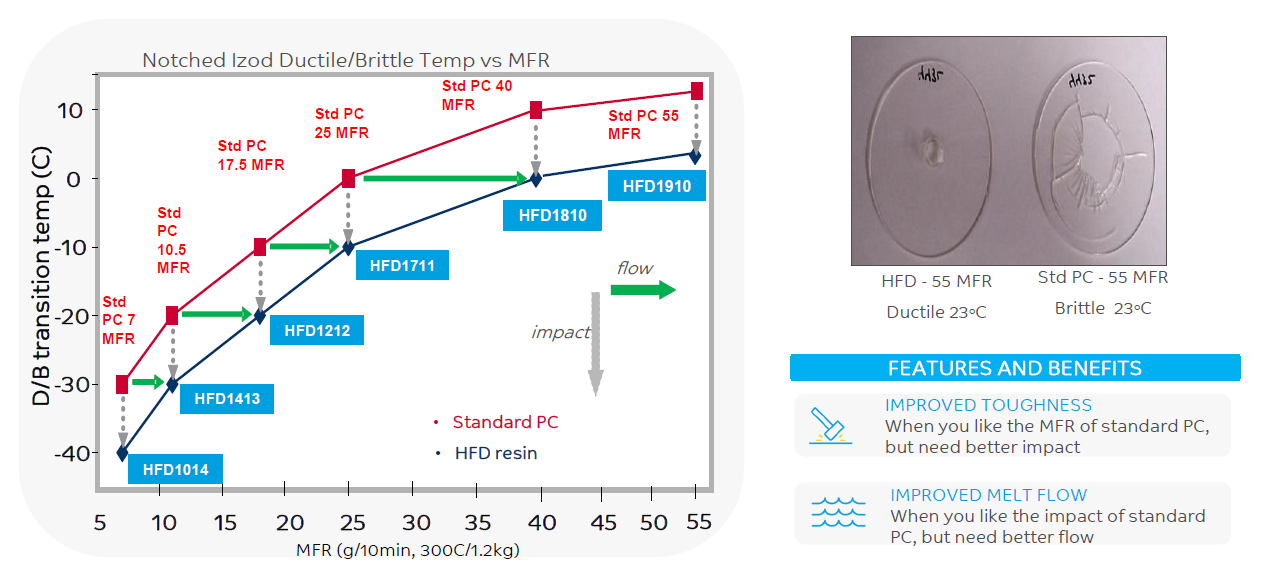

HFD RESIN - DUCTILITY ADVANTAGES

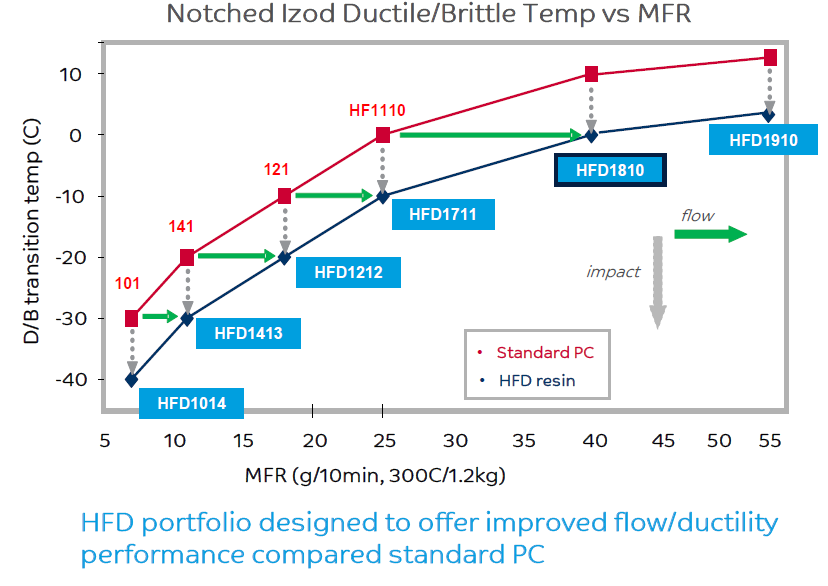

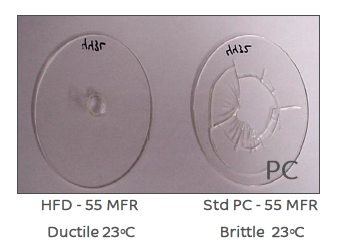

HFD VS. PC DUCTILITY AND MELT FLOW COMPARISON

When?

• When you like the MFR of standard PC, but need better impact

• When you like the impact of standard PC, but need better flow

Why?

• For a given melt flow, HFD resins has 10 15 o C better d/b transition temperature compared to standard PC

HFD RESINS GLASS FIBER FILLED INTRODUCTION

Compared to general purpose GF filled PC, GF HFD is an improved toughness/ductility with the same melt flow index or improved melt flow at the same toughness/ductility, ~20oC lower processing temperatures with good filled surfaces

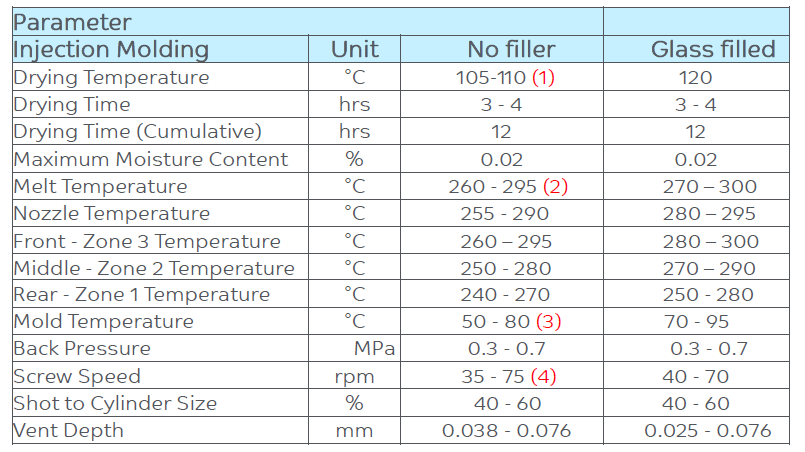

HFD RESINS - MOLDING CONDITION

1. Different drying temperature between filled and unfilled HFD

2. Low melt temperature molding

3. Higher mold temp result high gloss surface and more even inner stress. Under HD T 10 15 was suggested

4. Suggested low middle screw speed and which is dependent on screw diameter.

It is recommended to perform first molding in the presence of a SABIC Technical Development Engineer.

Summary

~20°C lower processing temperatures vs standard PC. It was good for IML/IMR molding

It is important to take care of sprue design at those small part applications, make it as short as possible when develop new targets at customer sites. The benefits for customer will be: Shorter cooling time, decreased cycle time, Decrease material consumption. Lower injection pressure drop, benefit to molding process

Application at chemical environment need to tested by customer

Secondary processes, e.g.. spray painting and hard coating need to be validated to confirm the compatibility, and the suitability of the material for the end use application. Low molded in stress is needed to prevent cracking after secondary process

HFD RESIN

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

THE MATERIALS, PRODUCTS AND SERVICES OF SAUDI BASIC INDUSTRIES CORPORATION (SABIC) OR ITS SUBSIDIARIES OR AFFILIATES (“SELLER ”) ARE SOLD SUBJECT TO SELLER’S STANDARD CONDITIONS OF SALE, WHICH ARE AVAILABLE UPON REQUEST. INFORMATION AND RECOMMENDATIONS CONTAINED IN THIS DO CUMENT ARE GIVEN IN GOOD FAITH. HOWEVER, SELLER MAKES NO EXPRESS OR IMPLIED REPRESENTATION, WARRANTY OR GUARANTEE ( i ) THAT ANY RESULTS DESCRIBED IN THIS DOCUMENT WILL BE OBTAINED UNDER END USE CONDITIONS, OR (ii) AS TO THE EFFECTIVENESS OR SAFETY OF ANY DESIGN OR APPLICATION INCORPORATING SELLER’S MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS. UNLESS OTHERWISE PROVIDED IN SELLER’S STANDARD CONDITIONS OF SALE, S ELLER SHALL NOT BE RESPONSIBLE FOR ANY LOSS RESULTING FROM ANY USE OF ITS MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS DESCRIBED IN T HIS DOCUMENT. Each user is responsible for making its own determination as to the suitability of Seller’s materials, products, serv ices or recommendations for the user’s particular use through appropriate end use and other testing and analysis. Nothing in any document or oral statement shall be deemed to alter or waive any provision of Seller’s Standard Conditions of Sale or this Disclaimer, unless it is specifically agreed to in a writing signed by Seller Statements by Seller concerning a possible use of any material, product, service or design do not, are not intended to, and should not be construed to grant any license und er any patent or other intellectual property right of Seller or as a recommendation for the use of any material, product, service or design in a manner that infringes any pa tent or other intellectual property right.

SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates.

©2023 Saudi Basic Industries Corporation (SABIC). All Rights Reserved.

Any brands, products or services of other companies referenced in this document are the trademarks, service marks and/or trade names of their respective holders.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience