BOUNDLESS+ DYNAMIC LNP™ SPECIALTY COMPOUNDS Advanced gear solutions

SABIC

Founded in 1976, SABIC is today the first public, global multinational enterprise headquartered in the Middle East. Our products range from bulk commodity chemicals to highly engineered plastics for demanding applications. We are a leading producer of polyethylene, polypropylene, glycols, methanol and fertilizers and the world’s third largest polyolefin producer.

SABIC’s offerings include Chemicals, Polymers, Specialties, Agri- Nutrients and metals. in Saudi Arabia, the Netherlands, Spain, the USA, India, China and Japan, our dedicated Technology & Innovation centers research ways to meet our customers’ needs with excellence.

INNOVATING FOR CUSTOMER SUCCESS

We believe that SABIC customers deserve the full benefit of every advantage our enterprise can offer. After all, our success is defined by our customers’ success. And with more than 80 years of experience pioneering advanced engineering thermoplastics, SABIC is positioned to help create new opportunities for growth and breakthrough applications.

We offer expertise and experience to our customers in a variety of ways:

• Material solutions to help drive innovation and market leadership.

• Design, logistics and processing expertise to spark new ideas and better efficiencies.

• Unwavering commitment to build long- term relationships with ingenuity, trust and continuous improvement.

It’s what we strive for and work to deliver… a mutual benefit.

Excellence and nothing less

ADVANCED GEAR SOLUTIONS

There are times when a single resin like POM may not provide the performance needed for advanced gears. The SABIC product portfolio is based on a variety of thermoplastic resins in combination with different internal lubricants.

• Available in >20 different resins

• Based on six different lubricants and

combinations

• Available in unfilled and filled versions (glass/carbon fiber, mineral)

• UL94 V0 grades are available

WHERE POM MAY NOT WORK

• High accuracy requirements

• Low noise requirements

• Tooth stress > 43 MPa

• Temperature >80 °C

• Enhanced wear and/or friction

• Agency flame requirement > HB

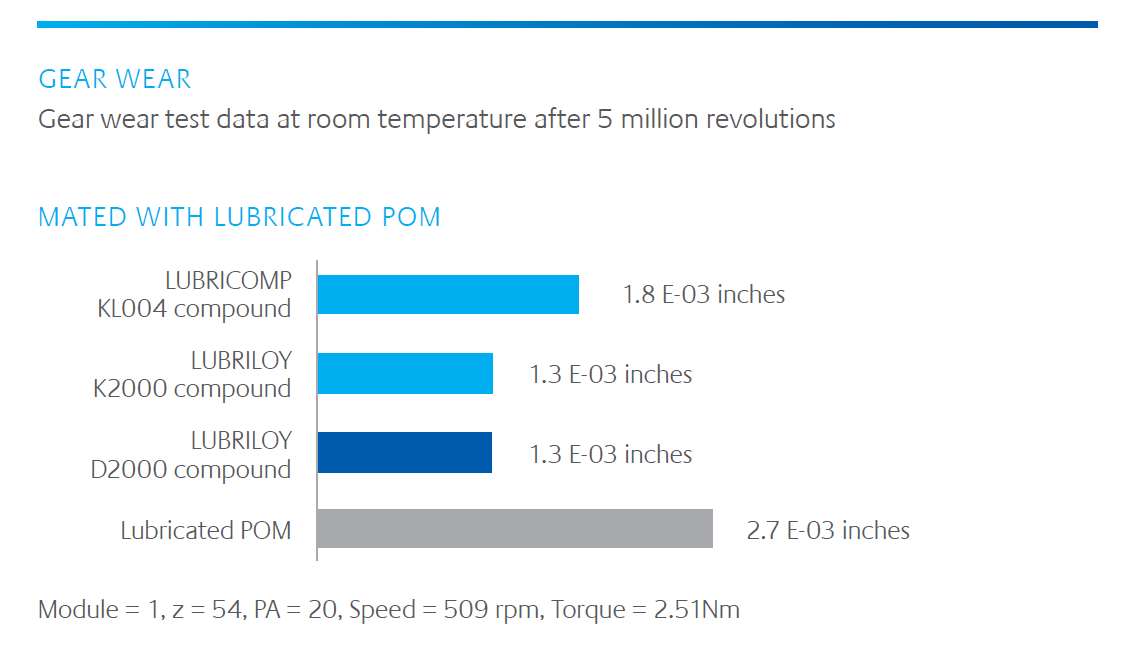

HIGH ACCURACY

• LUBRILOY™ D2000 compound

• LUBRILOY D20001 compound

• LUBRICOMP™ DFL36 compound

• LUBRICOMP EFL36 compound

• and other compounds

NOISE REDUCTION

• LUBRILOY R2000 compound

• LUBRILOY D2000 compound

• LUBRILOY D20001 compound

• LUBRICOMP KL004 compound

• and other compounds

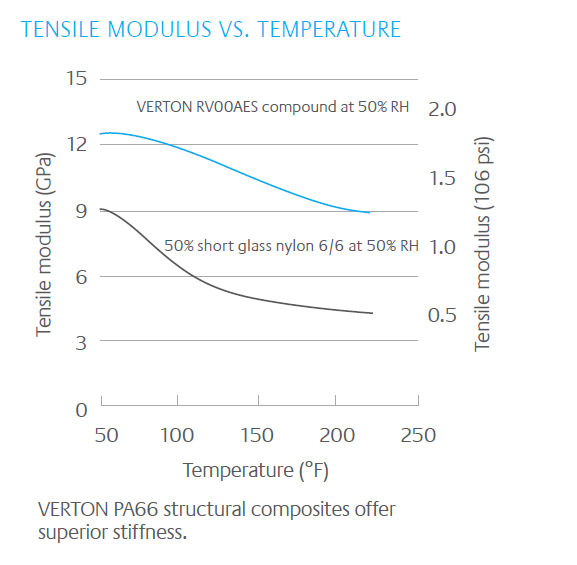

HIGH HEAT/HIGH TORQUE

• LUBRICOMP EFL36 compound

• LUBRICOMP OFL36 compound

• LUBRICOMP UFL36S compound

• VERTON™ RV00AES compound

• and other compounds

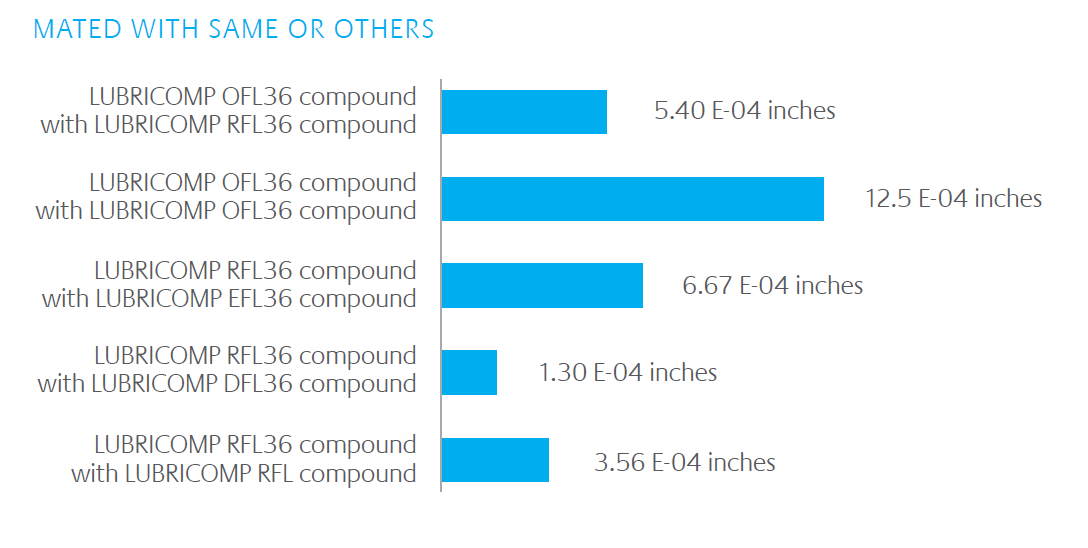

PRIMARY GEAR GRADES

LU BRILOY D2000 compound PC High impact, good dimensional stability

LU BRILOY D2001 compound PC (FR) Environmentally friendly flame resistance, good dimensional stability

LU BRILOY R2000 compound PA66 Good chemical resistance, low SG and noise

LUBRICOMP KL004 compound POM, PTFE Low wear factor, superior friction

LUBRICOMP DFL36 compound PC, GF & PTFE High strength, good dimensional stability

LUBRICOMP WFL36 compound PBT, GF & PTFE High strength, well-balanced performance

LUBRICOMP RFL36 compound PA66, GF & PTFE High strength, good chemical resistance

LUBRICOMP OFL36 compound PPS, GF & PTFE High strength, high heat resistance

LUBRICOMP EFL36 compound PEI, GF & PTFE High heat resistance, good dimensional stability

LUBRICOMP UFL36S compound PPA, GF & PTFE Exceptional L-PV, high heat resistance

LUBRICOMP LCL33E compound PEEK, CF & PTFE Superior high heat resistance, high strength

VERTON RV 00AES compound PA66, L-GF Superior high strength, good weld-line strength

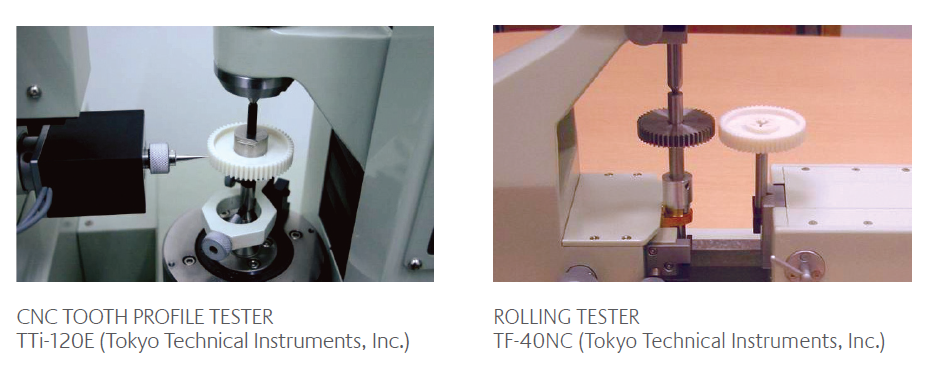

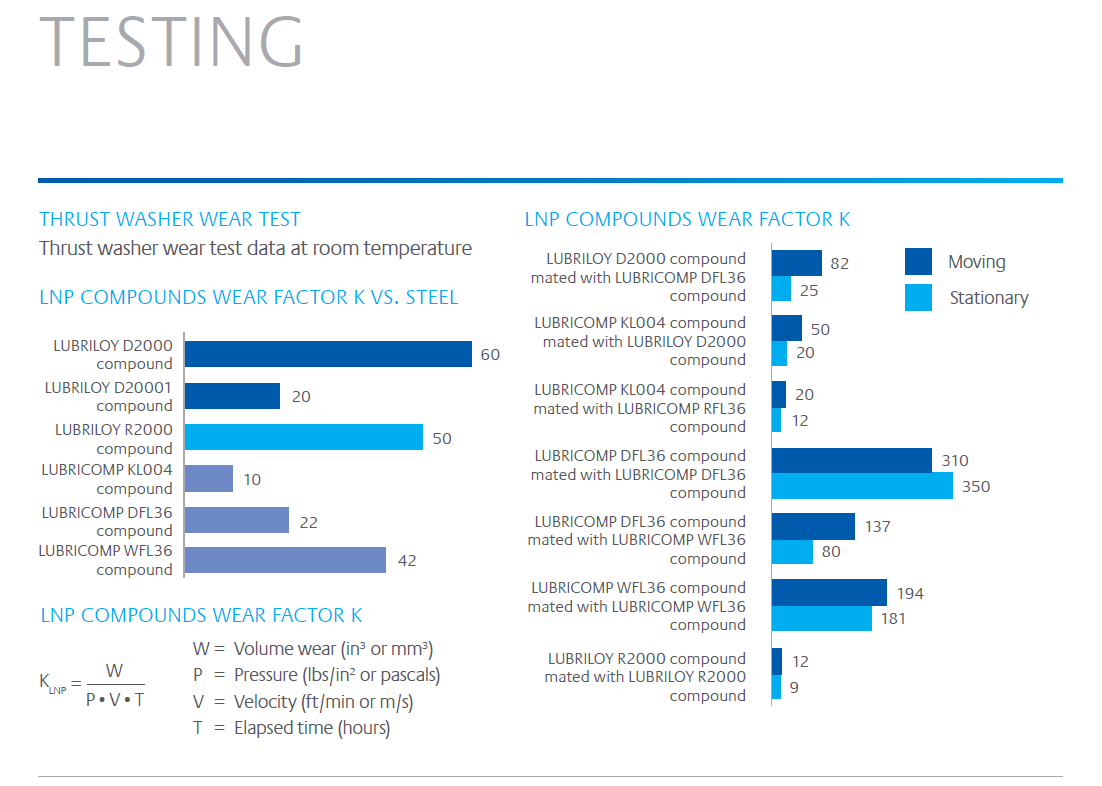

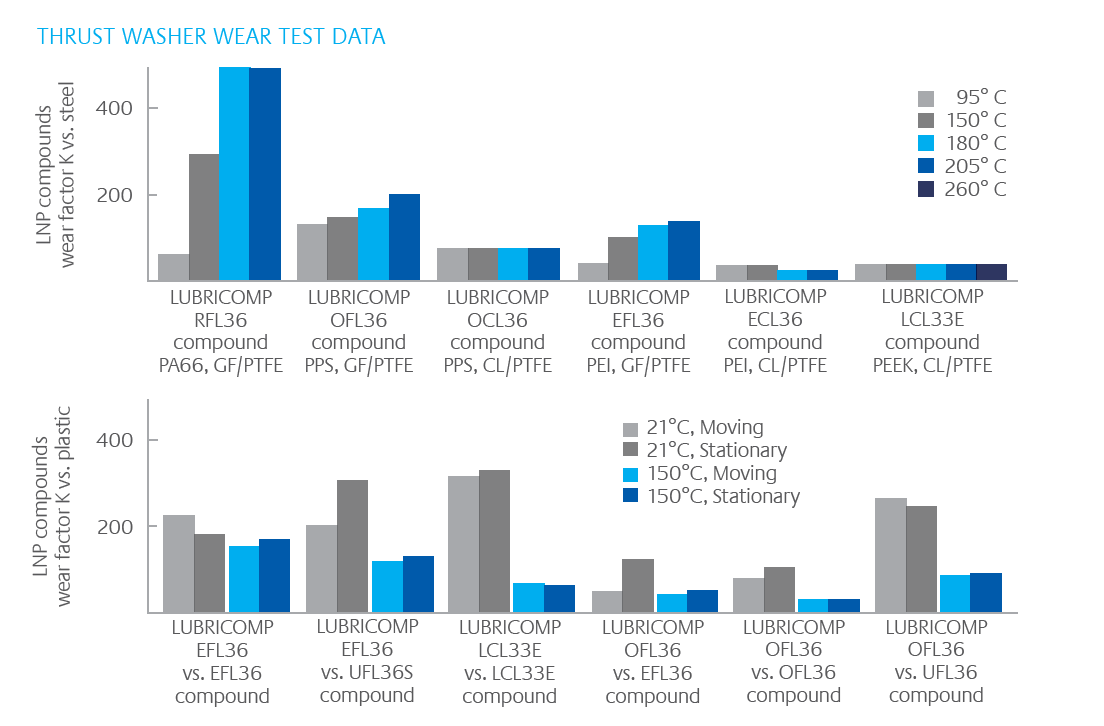

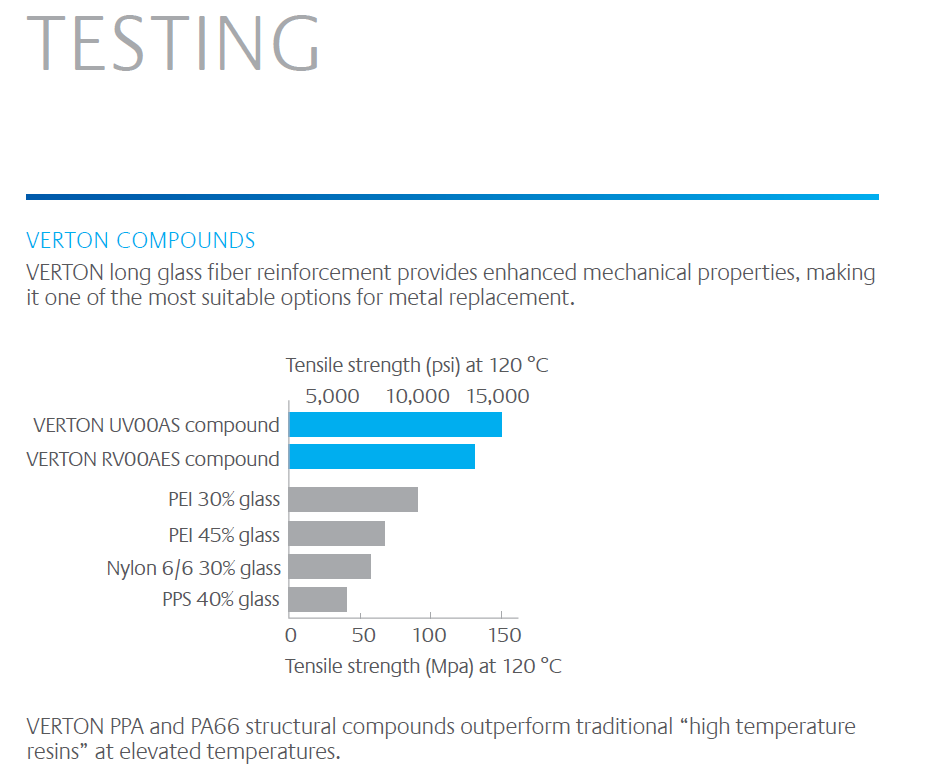

TESTING

ACCURACY

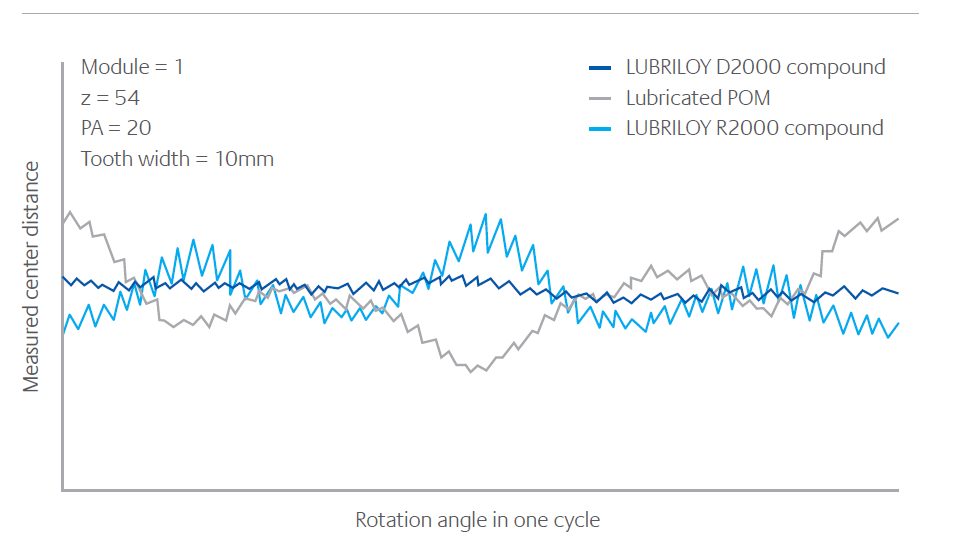

A rolling test is a typical way of measuring gear accuracy. A dual contact rolling test detects the center distance between the master gear (which is of known high quality) and the sample gear, as they are forced to mesh with each other. The measured value is the composite gear error.

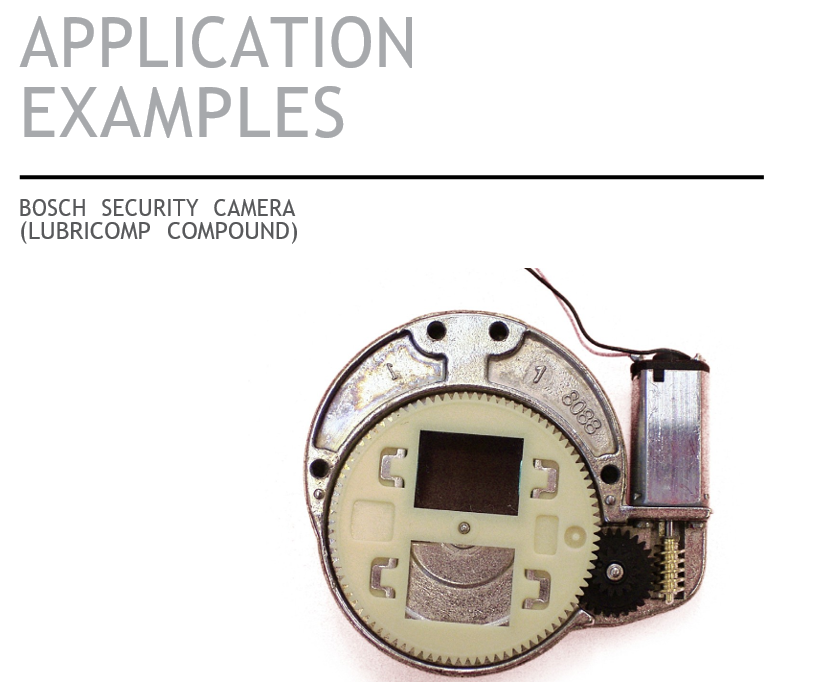

METAL REPLACEMENT

LNP specialty compounds are ideal for replacing metal gears. They can offer design flexibility and improved performance over the life of the product as well as manufacturing advantages and cost savings.

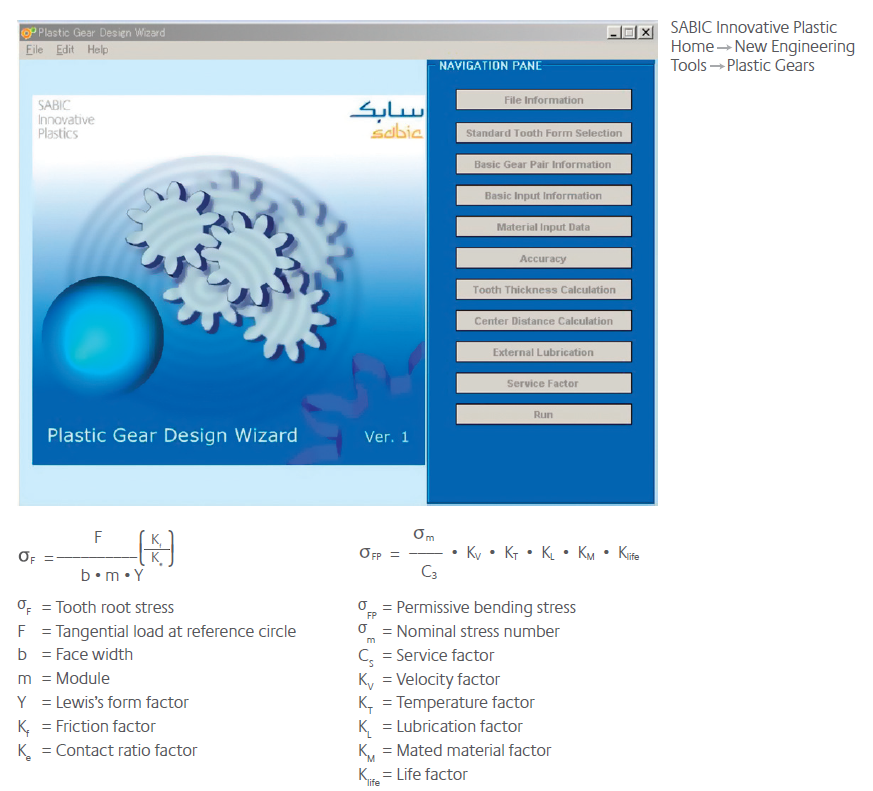

PLASTIC GEAR DESIGN WIZARD (PGDW)

PGDW is a software that calculates “tooth root stress” using the Lewis equation; it calculates material “permissible bending stress” based on SABIC’s Innovative Plastics business’ original algorithm.

• Plastic material focus – Incorporating database from SABIC’s Innovative Plastics business

• Internal technical analysis standard for plastic gears – New design methodology to translate the material data into gear analysis data

• New gear design factor introduction – Friction factor/contact ratio factor

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

DISCLAIMER: THE MATERIALS, PRODUCTS AND SERVICES OF SAUDI BASIC INDUSTRIES CORPORATION (SABIC) OR ITS SUBSIDIARIES OR AFFILIATES (“SELLER”) ARE SOLD SUBJECT TO SELLER’S STANDARD CONDITIONS OF SALE, WHICH ARE AVAILABLE UPON REQUEST. INFORMATION AND RECOMMENDATIONS CONTAINED IN THIS DOCUMENT ARE GIVEN IN GOOD FAITH. HOWEVER, SELLER MAKES NO EXPRESS OR IMPLIED REPRESENTATION, WARRANTY OR GUARANTEE (i) THAT ANY RESULTS DESCRIBED IN THIS DOCUMENT WILL BE OBTAINED UNDER END-USE CONDITIONS, OR (ii) AS TO THE EFFECTIVENESS OR SAFETY OF ANY DESIGN OR APPLICATION INCORPORATING SELLER’S MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS. UNLESS OTHERWISE PROVIDED IN SELLER’S STANDARD CONDITIONS OF SALE, SELLER SHALL NOT BE RESPONSIBLE FOR ANY LOSS RESULTING FROM ANY USE OF ITS MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS DESCRIBED IN THIS DOCUMENT. Each user is responsible for making its own determination as to the suitability of Seller’s materials, products, services or recommendations for the user’s particular use through appropriate end-use and other testing and analysis. Nothing in any document or oral statement shall be deemed to alter or waive any provision of Seller’s Standard Conditions of Sale or this Disclaimer, unless it is specifically agreed to in a writing signed by Seller. Statements by Seller concerning a possible use of any material, product, service or design do not, are not intended to, and should not be construed to grant any license under any patent or other intellectual property right of Seller or as a recommendation for the use of any material, product, service or design in a manner that infringes any patent or other intellectual property right.

SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates.

© 2023 Saudi Basic Industries Corporation (SABIC). All Rights Reserved.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience