LNP™ COMPOUNDS - WEAR AND FRICTION SOLUTIONS - BEARINGS, BUSHINGS, CAMS AND SLIDERS

At the push of a button, windows move, doors lock, copies get made, and HVAC comes to life. These electromotive actions require gears, bearings, bushings, and other wear surfaces to provide smooth, reliable, actuation forces. LUBRICOMP™ and LUBRILOY™ compounds can help deliver the high-quality performance required.

THERMOPLASTIC BEARINGS

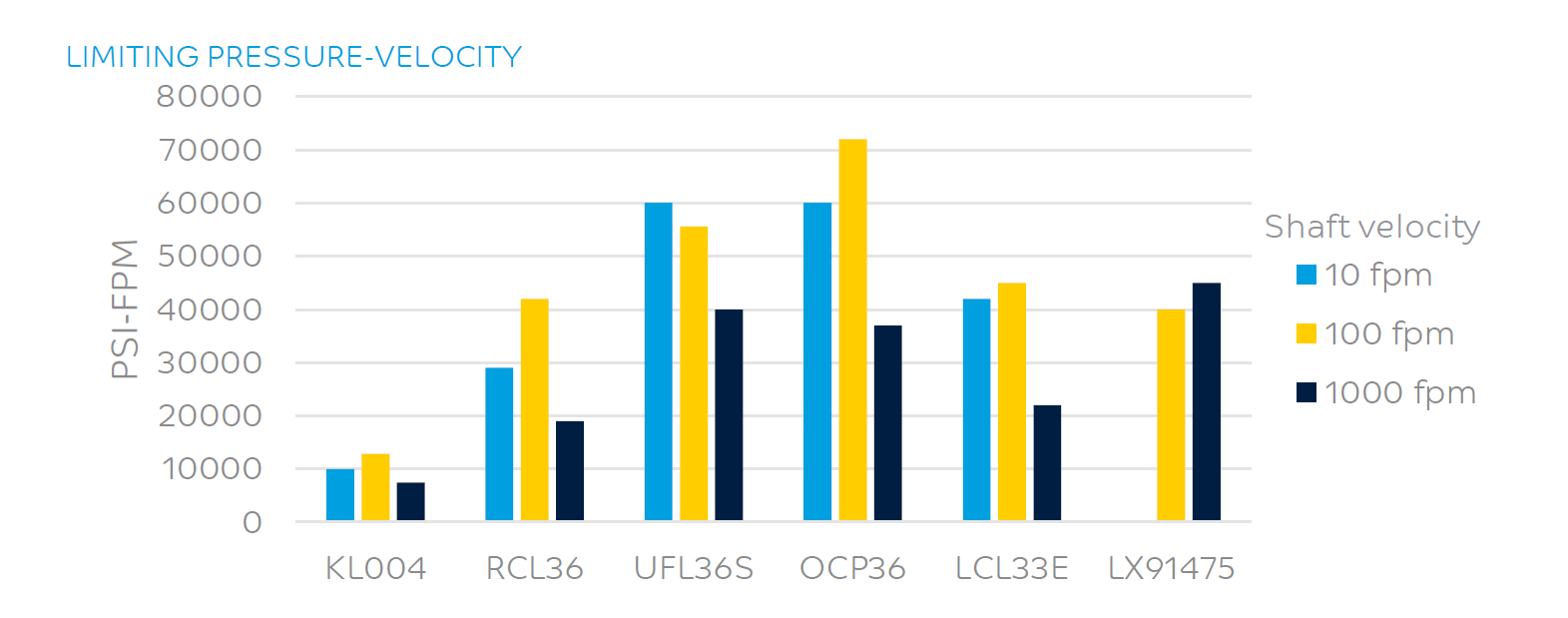

While resistance to wear is important for thermoplastic bushings/bearings, low friction can be more important. Heat generated from friction is often the limiting factor in plastic bearing applications. The operating load (P) and speed (V) of the application can be compared to the allowable, or “Limiting PV” of a candidate material. The data shown below was generated using a cylindrical half bearing test configuration, but modern thrust washer testers can be used to develop PV maps as well.

INTERNALLY LUBRICATED COMPOUNDS

The addition of an internal lubricant to a thermoplastic material can improve the wear resistance and reduce the coefficient of friction in plastic parts. Traditional lubricants like MoS2, PTFE and PTFE/Si blends are common, with reinforcements like glass and carbon fibre adding strength and modulus. High temperature resins are sometimes required to resist deformation from friction generated heat.

WEAR AND FRICTION SOLUTIONS - EARINGS, BUSHINGS, CAMS AND SLIDERS

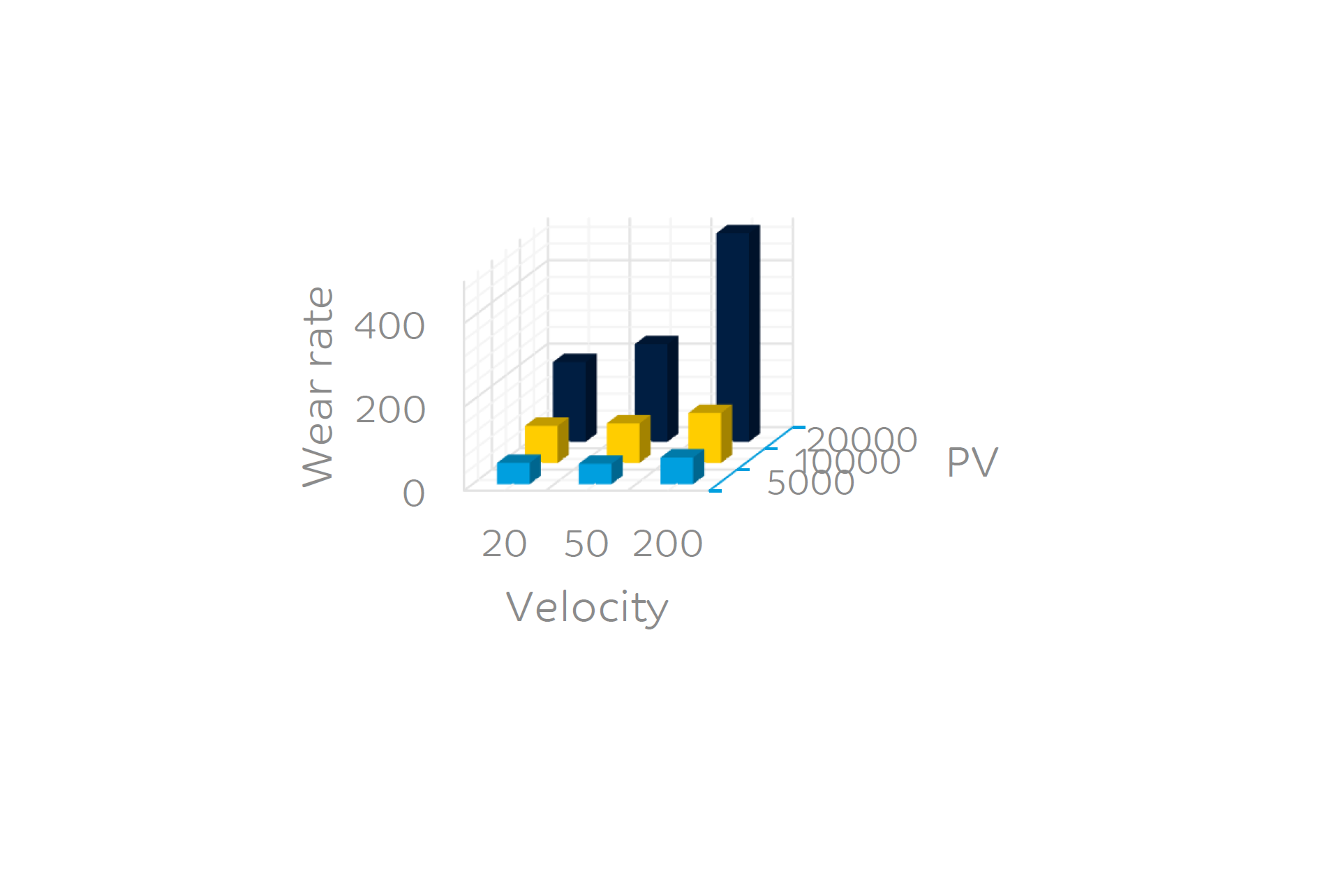

In addition to the journal bearing test described earlier, material performance data can be generated by doing thrust washer wear testing at multiple loads (P) and speeds (V). Plotting the results for wear rate, COF and temperate can give insight into the performance window of a particular grade. Data shown at left is multipoint wear rate data for LUBRICOMP UFL36S.

Thermoplastic Gearing solutions

| Grade | Description | Features |

| LUBRICOMP LX91475 | PEEK, carbon fiber, graphite, PTFE | FM: 10.3 GPa, HDT: 335C, chemical resistance, superior bearing performance, UL94-V0@0.720mm |

| LUBRICOMP LCL33E | PEEK, 15% carbon fiber, 15% PTFE

| FM: 14.7 GPa, HDT: >240C, low wear and friction, UL94- V0@1.5mm |

| LUBRICOMP OCP36 | PPS, 30% carbon fiber, 15% PTFE/Si | FM: 33.9 GPa, HDT: 266C, chemical resistance, excellent wear/bearing performance, UL94-V0@0.94mm |

| LUBRICOMP UFL36S | PPA, 30% glass fiber, 15% PTFE | FM: 11.2 GPa, HDT: 255C, Good balance of cost and performance, low wear and COF |

| LUBRICOMP

JX91198 | PES, carbon fiber,

graphite, PTFE | FM: 9.24 GPa, HDT: 228C, tight dimensional tolerance,

superior wear and bearing performance. |

| LUBRICOMP RCP36 | PA66, 30% carbon fiber, 15% PTFE/Si | FM: 21.3 GPa, chemical resistant, superior wear and bearing performance. |

| LUBRICOMP RLF36S | PA66, 30% glass fiber, 15% PTFE | FM: 9.7 GPa, Baseline grade for structural applications, low wear and COF, good chemical resistance. |

| LUBRICOMP RAL22 | PA66, 10% aramid fiber, 10% PTFE | Good wear against aluminum and in abrasive environments, low wear and COF |

| LUBRICOMP RN001S | PA66, MoS2

lubricated | Traditional bushing grade. Some reduction in slip-stick behavior. Good chemical resistance |

| LUBRICOMP KN001 | POM, MoS2

lubricated | Traditional bushing grade. Some reduction in slip-stick behavior. Good chemical resistance |

| LUBRICOMP KP004 | POM, 20% PTFE/Si | Very low wear and COF, good chemical resistance |

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

DISCLAIMER: Any sale by SABIC, its subsidiaries and affiliates (each a “seller”), is made exclusively under seller’s standard conditions of sale (available upon request) unless agreed otherwise in writing and signed on behalf of the seller. While the information contained herein is given in good faith, SELLER MAKES NO WARRANTY, EXPRESS OR IMPLIED, INCLUDING MERCHANTABILITY AND NONINFRINGEMENT OF INTELLECTUAL PROPERTY, NOR ASSUMES ANY LIABILITY, DIRECT OR INDIRECT, WITH RESPECT TO THE PERFORMANCE, SUITABILITY OR FITNESS FOR INTENDED USE OR PURPOSE OF THESE PRODUCTS IN ANY APPLICATION. Each customer must determine the suitability of seller materials for the customer’s particular use through appropriate testing and analysis. No statement by seller concerning a possible use of any product, service or design is intended, or should be construed, to grant any license under any patent or other intellectual property right. SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates, unless otherwise noted.

© 2023 Saudi Basic Industries Corporation (SABIC). All Rights Reserved.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience