SPECIALTIES SOLUTIONS FOR WATER MANAGEMENT

SABIC

Founded in 1976, SABIC is today the first public, global multinational enterprise headquartered in the Middle East. Our products range from bulk commodity chemicals to highly engineered plastics for demanding applications. We are a leading producer of polyethylene, polypropylene, glycols, methanol and fertilizers and the world’s third largest polyolefin producer.

SABIC’s offerings include Chemicals, Polymers, Specialties, Agri-Nutrients and Metals. In Saudi Arabia, the Netherlands, Spain, the USA, India, China and Japan, our dedicated Technology & Innovation centers research ways to meet our customers’ needs with excellence.

INNOVATING FOR CUSTOMER SUCCESS

We believe that SABIC customers deserve the full benefit of every advantage our enterprise can offer. After all, our success is defined by our customers’ success. And with more than 80 years of experience pioneering advanced engineering thermoplastics, SABIC is positioned to help create new opportunities for growth and breakthrough applications.

We offer expertise and experience to our customers in a variety of ways:

- Material solutions to help drive innovation and market leadership.

- Design, logistics and processing expertise to spark new ideas and better efficiencies.

- Unwavering commitment to build long-term relationships with ingenuity, trust and continuous improvement.

It’s what we strive for and work to deliver… a mutual benefit.

Excellence and nothing less.

INTRODUCTION

SABIC– A LEADING EDGE SUPPLIER

Global water availability, efficiency and quality are critical needs for our future. Water equipment suppliers work to ensure access to clean drinking water and are instrumental in the repair and replacement of the existing water infrastructure. Products in constant contact with water require unique materials that provide long-term durability and hydrolytic stability, and oftentimes, metals are not the optimal choice due to corrosion or lifetime cost. With over 30 years of experience, SABIC is a pioneer in metal to plastics conversion for water applications. We can help the global water industry meet today’s challenges and exceed tomorrow’s goals with advanced material and design capabilities tailored for whole system performance.

SABIC offers a unique portfolio of high performance engineering resins and world-class application development support facilities. We are firmly focused on helping our customers to achieve their goals of enhanced system efficiency and competitive edge.

RESHAPING THE FUTURE, TODAY

Our portfolio of materials for water management has revolutionized products ranging from pumps, to water meters, to piping and even hot water heaters. We have worked with our customers to deliver cost reduction and improved lifetime performance in demanding operating environments.

‡ Chemical resistance is dependant on chemical used, resin type, exposure time, temperature and other factors.

Our solutions for water management are most often derived from the following SABIC materials:

- NORYL™ resins (PPE blends) for excellent hydrolytic stability

- NORYL GTX™ resin for remarkable heat and chemical resistance‡

- CYCOLAC™ resins (ABS material) for excellent platability, processability and gloss

- LNP™ specialty compounds for customized performance

- ULTEM™ resin (a PEI material) for unparalleled mechanical performance in high heat, chemically challenging environments

- LEXAN™ resin (a PC material) for ductility and transparency

SABIC’s materials continue to evolve, ensuring that customers receive outstanding performance combined with unique design and productivity benefits:

- System cost-out

- Long-term hydrolytic stability

- Resistance to fatigue and creep rupture

- Potable water safety

- High heat resistance

- Chemical‡ and contaminant resistance

- Corrosion resistance

- Regulatory compliance

WATER MANAGEMENT PORTFOLIO

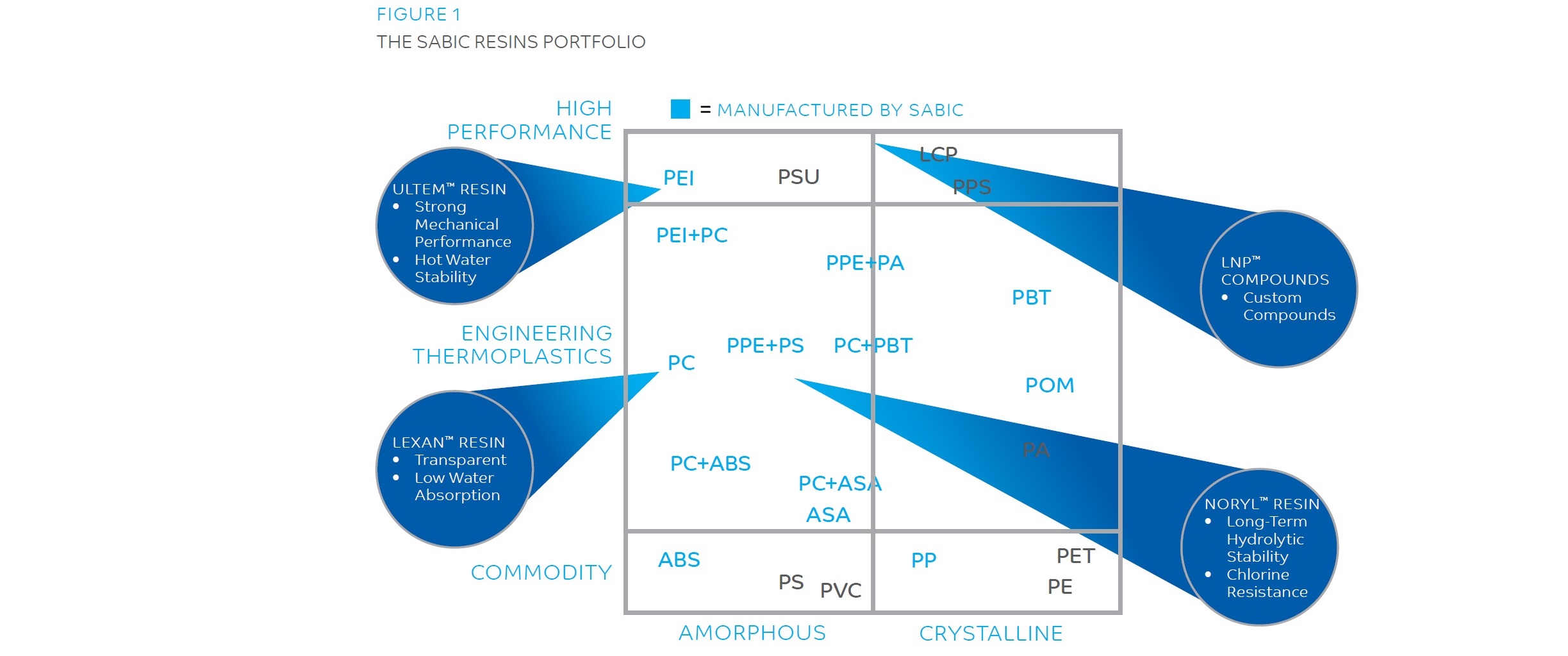

Amorphous materials such as SABIC’s NORYL™, ULTEM™ and CYCOLAC™ resins exhibit good creep behavior - deforming less under a constant pressure load than semi-crystalline resins. Additionally, with lower shrinkage during cooling, amorphous materials have more stable dimensions and less thermal expansion during part usage.

Semi-crystalline materials, such as SABIC’s NORYL GTX™ resin or most glass-filled polyamide resins, provide more mechanical integrity below their melt temperature. Compared to amorphous materials, these resins typically perform better in fatigue conditions but creep more under a constant load. Lastly, semi-crystalline resins will have greater mold shrink-age and higher thermal expansion.

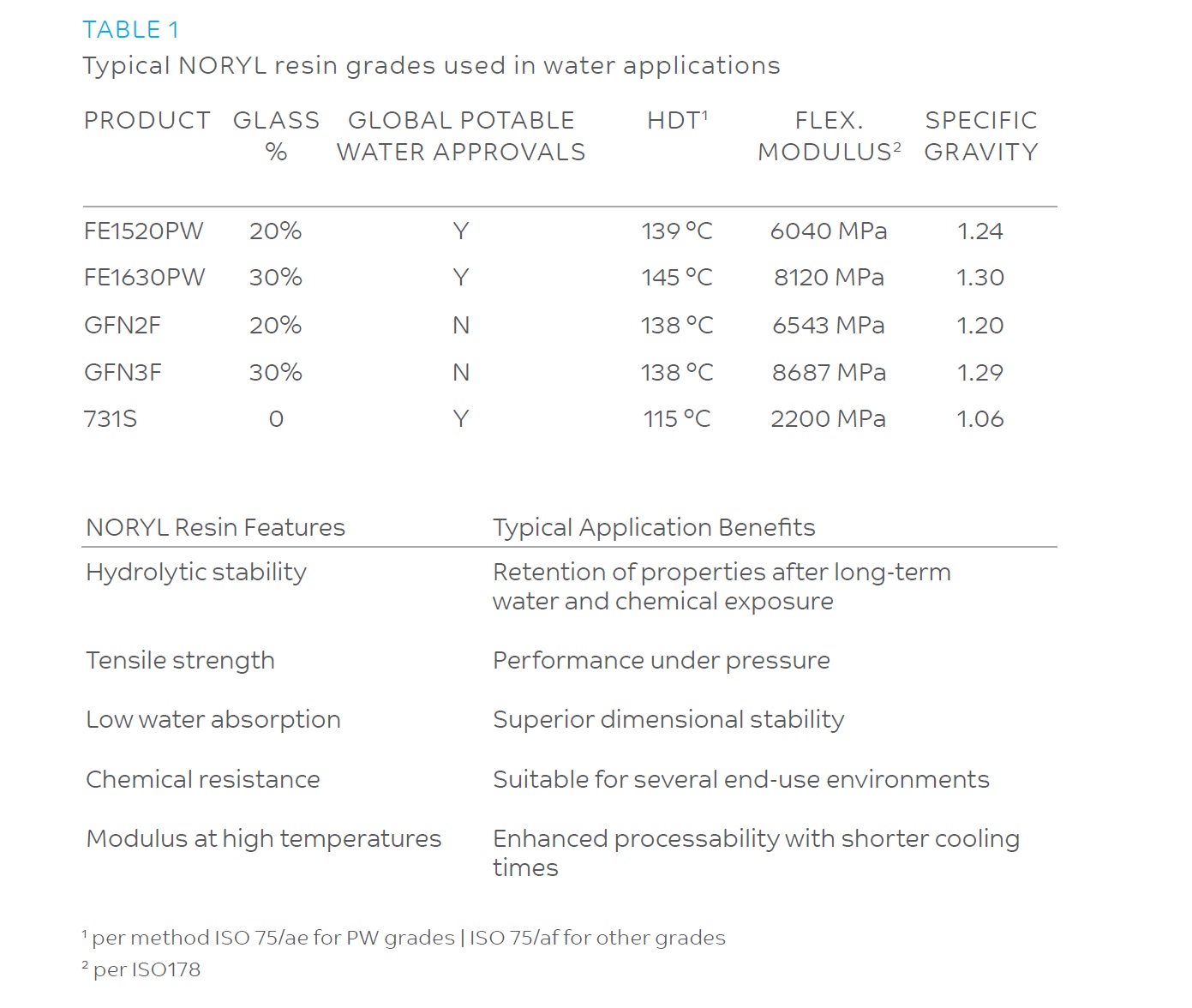

INTRODUCTION: NORYL™ RESIN IN WATER MANAGEMENT

One of the most comprehensive solutions for the water industry to design with thermoplastics is SABIC’s NORYL resin. Based on proprietary modified polyphenylene ether (PPE) technology, this extremely versatile resin portfolio offers customers a wide variety of material solutions to meet specific application requirements. With their best-in-class hydrolytic stability and excellent high heat resistance, these grades are engineered to perform in both hot and cold water handling applications.

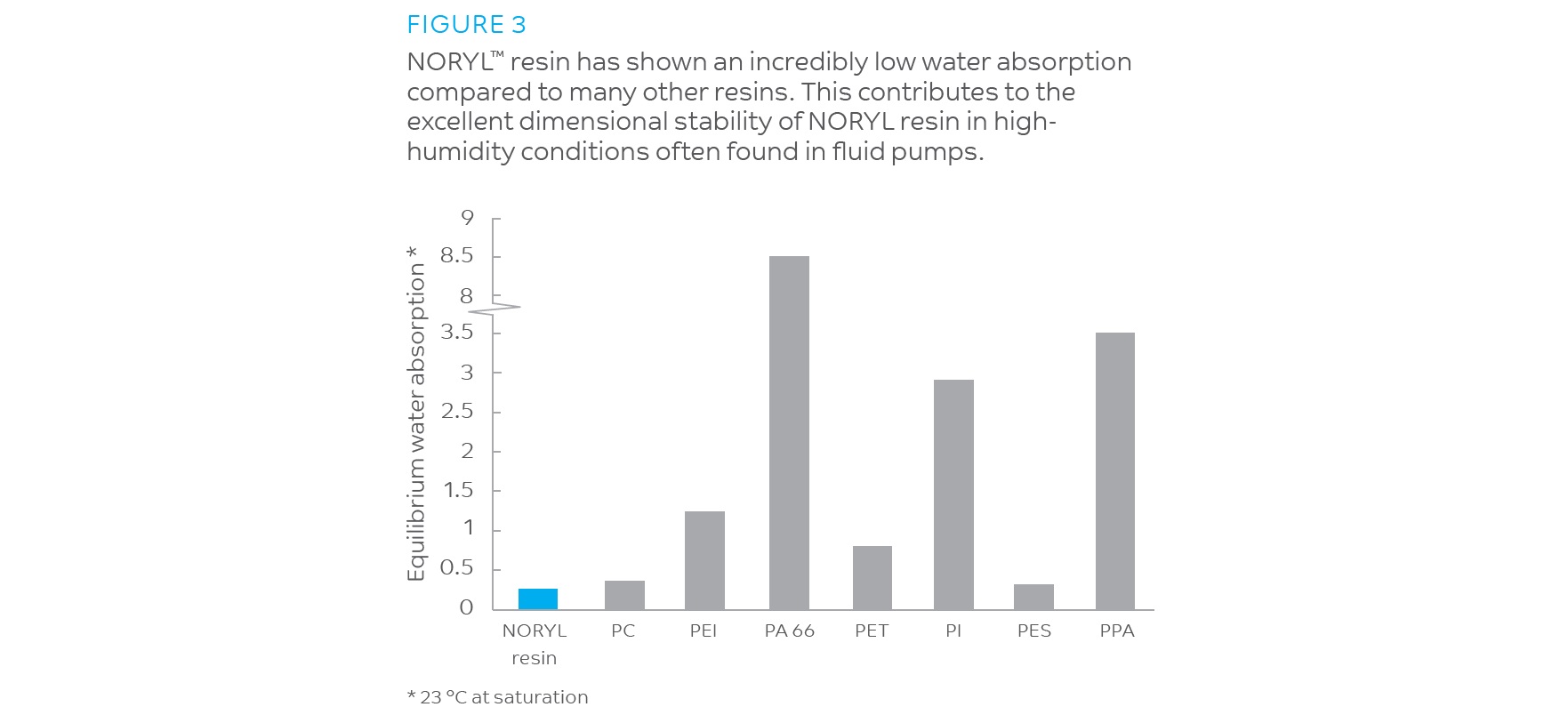

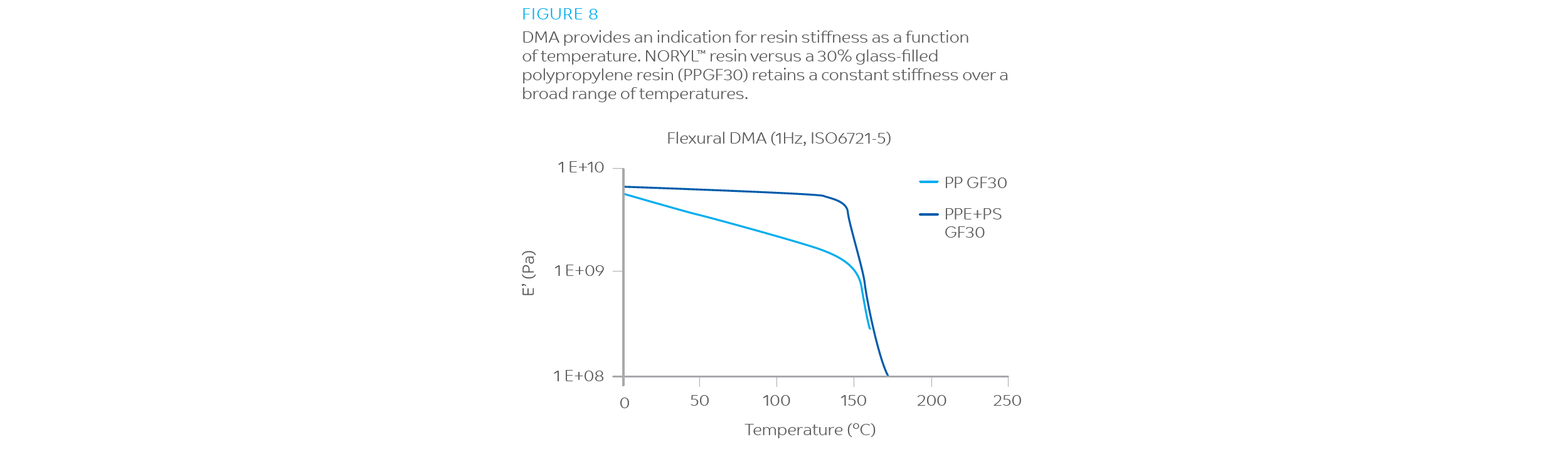

An amorphous blend of PPE resin and polystyrene (PS), NORYL resin is characterized by excellent dimensional stability, low mold shrinkage, low water absorption and excellent creep resistance.

With one of the lowest specific gravities of all engineering thermoplastics in its class, NORYL resin provides designers with opportunities to create lighter, more cost-efficient parts. Furthermore, the structural performance of NORYL resin can assist with easy part consolidation and assembly. Fewer parts and reduced secondary operations help to achieve higher yields, improved quality and lower costs.

INNOVATION FROM A SINGLE SOURCE

Our goal is to assure our customers that our commitment to leading-edge supply and service extends well beyond the pellet.

SABIC combines experience across several businesses, regions and even industries to solve material and processing challenges in water applications. We regularly assess the industry needs together with our portfolio to identify new innovations that our customers will value. A recent material innovation includes the introduction of our NORYL™ potable water resin portfolio. This series of resins is designed to meet tightening European potable water specifications around the glass fiber technology used in contact with food and water. NORYL potable water polymers are offered in 10, 20, 30 and 40% glass blends which are in compliance with January 2016 FCEU regulations.

SABIC has one of the most advanced global application development facilities in the industry with capabilities which include:

- Advanced design and engineering

- Dedicated computer aided design services

- Materials characterization and testing facilities

- Fully equipped processing laboratories

CONCEPT GENERATION

SABIC works closely with its customers to help them develop fluid engineering concepts that are based on a thorough understanding of the industry, engineering materials and manufacturing processes.

Based on this knowledge, these initial concepts can be converted successfully into real parts, which are focused on meeting specific industry needs, satisfying stringent industry standards, optimizing manufacturing costs and reducing time to market.

MATERIAL SELECTION

Once the preliminary design has been established, SABIC provides customers with a wealth of material data for their application development. Customers are invited to visit the company’s website at sabic.com for an introduction to the wide range of materials. Due to the complicated environments where water equipment is used, customers are urged to contact their local SABIC representative before using this basic data for application development.

WATER MANAGEMENT CENTER OF EXCELLENCE

Water industry customers have access to SABIC’s dedicated water application development center. This unique facility helps support worldwide application development needs, assisting customers in all phases of their design process.

Our research center is able to test long-term performance of polymers and parts using tensile bars, customer parts and pressure vessels. We test in accordance with regional and global industry standards. The Center’s scientists and technologists help customers to develop new and innovative applications by simulating real-life water environments in the lab. This work is complemented by ongoing research into new processing technologies and assembly techniques to help meet the special requirements of water management applications.

- Areas of specific expertise include:

- The effect of small amounts of chlorine in water, combined with oxygen

- Hot water resistance

- Creep rupture and fatigue testing

- Wear and erosion resistance

- Vibration and laser welding

- Burst pressure

- Regulatory compliance

- Anisotropic 3D predictive modelling for design and process optimization

BEYOND THE DATASHEET

It is critical to look beyond the datasheet properties when designing for water equipment that must endure high pressure. SABIC’s Water Management Center of Excellence delivers data on material performance in areas such as weld line performance and chemical compatibility, critical for most metal to plastic part transitions. SABIC supplies long term data on material behavior, which in some cases includes data after 4,000 hours of testing. We have applied expertise in thermoplastic parts under cold and hot water, in fluids such as engine coolant mixtures, and even those in gaseous fluid environments such as refrigerants. Our Center of Excellence team has particular experience in handling anisotropic environments and in identifying solutions to overcome glass orientation and weld line concerns.

SABIC™ PREDICTIVE ENGINEERING SERVICES

Conventional simulation methods, which assume simple isotropic material properties, may inadequately predict the true performance of complex parts. The anisotropic behavior in glass-filled molded parts is critical to consider when predicting the long-term durability under stress loading. Our SABIC Predictive Engineering Services featuring fiber-reinforced NORYL™ resin may help customers save valuable resources while improving new product confidence and decreasing time to market.

APPLICATIONS

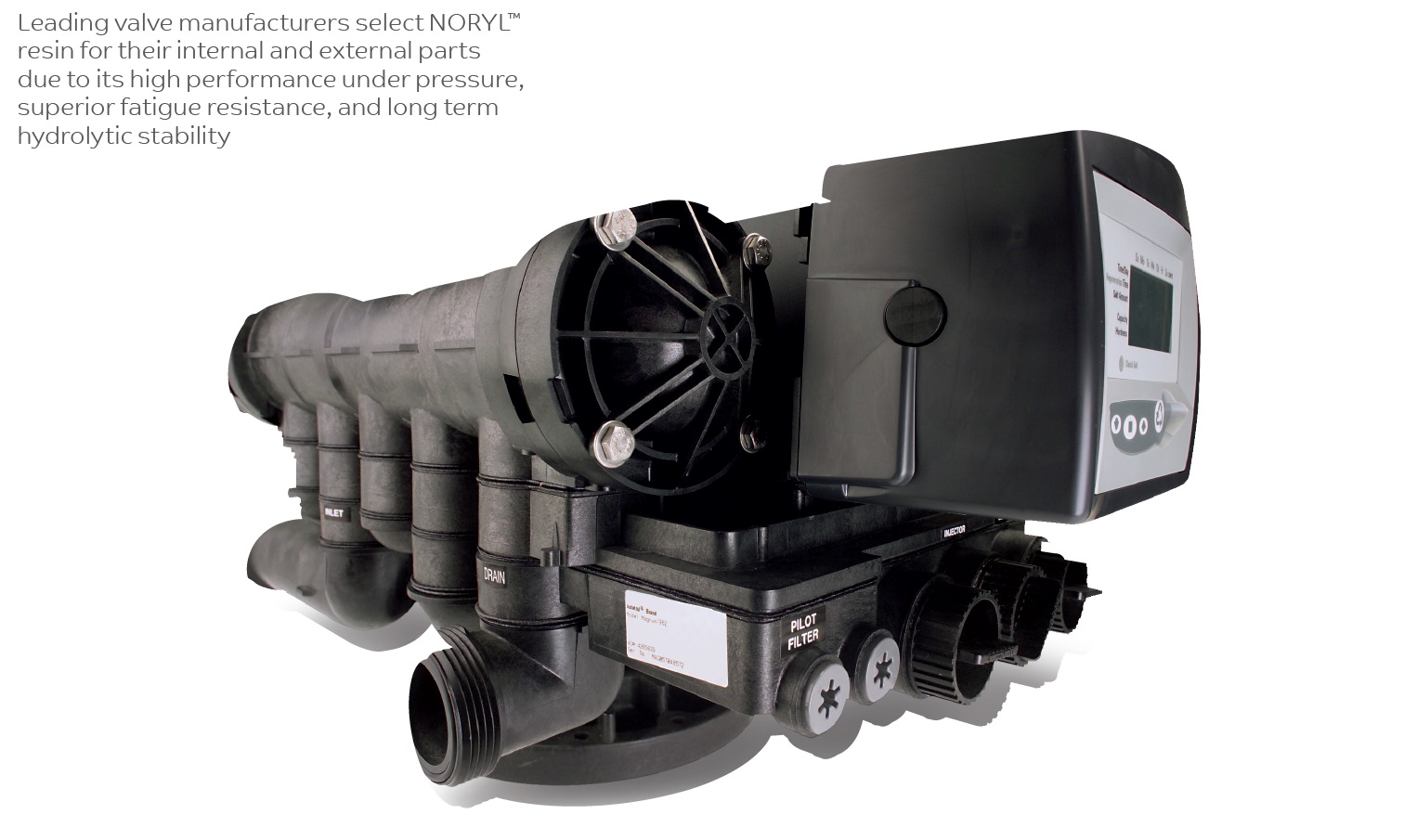

PUMPS AND VALVES

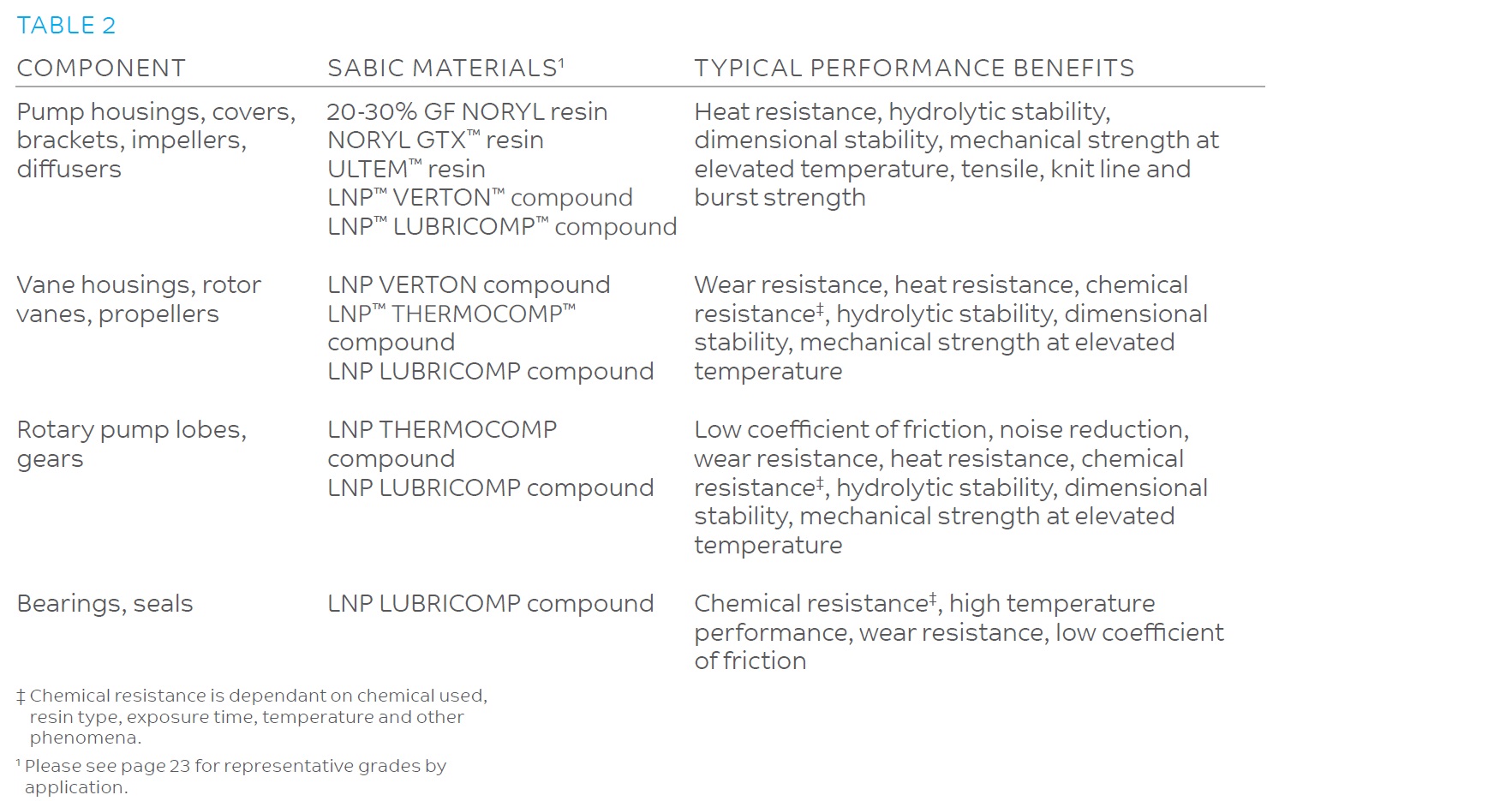

In components such as pump housings, covers, brackets and impellers, SABIC resins may help to reduce system cost, improve efficiency and minimize maintenance. Material selection depends on specific operating conditions.

SABIC has worked with leading pump manufacturers on parts ranging from impellers to gears and housings. With our wide range of engineering thermoplastics, SABIC can assist in designing new or existing parts which meet or can even exceed functional and regulatory requirements.

NORYL™ resin can deliver excellent hydrolytic stability to pump applications where parts are constantly exposed to water. Glass fiber-reinforced products such as NORYL GFN3 resin can provide reliable dimensional stability to help meet burst pressure , long term creep and material fatigue requirements of parts such as housings and impellers.

LNP™ VERTON™ compounds can provide exceptional mechanical performance. For highly demanding applications such as submersible pump housings, these remarkably lightweight materials combine rigidity with outstanding strength and resistance to impact. They can provide dimensional stability during use—even as the motor generates high heat—and resist water absorption, corrosion and scaling. LNP™ LUBRCOMP™ compounds are internally-lubricated materials using additives such as fluoropolymers and graphite. These compounds can offer unique advantages to metal in pump internal parts such as long-term performance and resistance to corrosion for impellers.

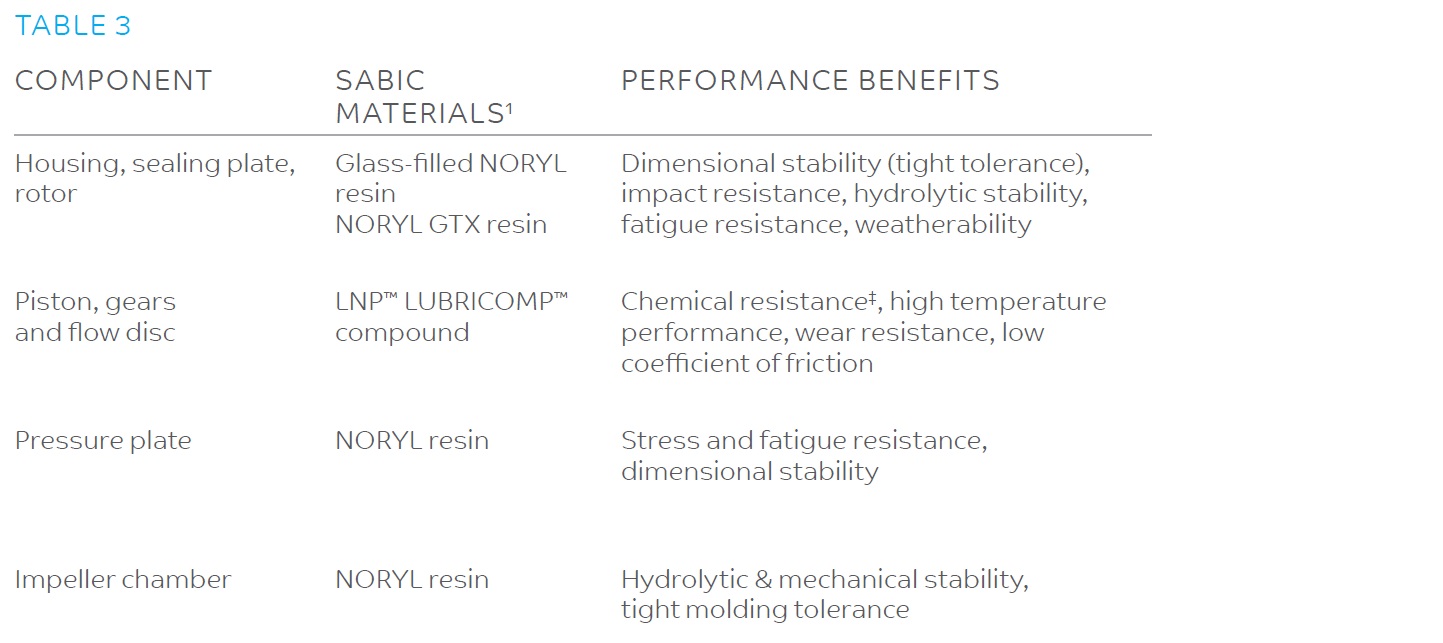

WATER METERS

Global restrictions on lead in our water systems have required brass foundries to create new low-lead alloys for compliance. Compared to conventional brass, the low-lead brass alternatives can be difficult to machine, are more expensive and have a higher carbon footprint as they contain little recycled content. NORYL™ resin has enabled lead-free compliance in potable water meters by replacing brass meter bodies and internal parts including flow discs and sealing plates in both residential and industrial water meters.

In applications that require chemical resistance, NORYL GTX™ resin can provide long-lasting high performance. In the Badger Meter water meter housing, NORYL GTX resin helps the part to withstand repeated exposure to a wide range of environments, including lawn chemicals and chlorinated water. Furthermore, the resin exhibits excellent mechanical properties, consistent hydrolytic stability and dependable dimensional stability compared to nylon.

For internal water meter parts, Neptune Technology Group selected a customized LNP™ LUBRICOMP™ compound made from a blend of PPE and other additives for the chamber and disc of their successful T-10 meters. LNP LUBRICOMP compounds provided superior hydrostability, wear, and chlorine resistance while meeting new lead-free NSF/ANSI 61 water regulations.

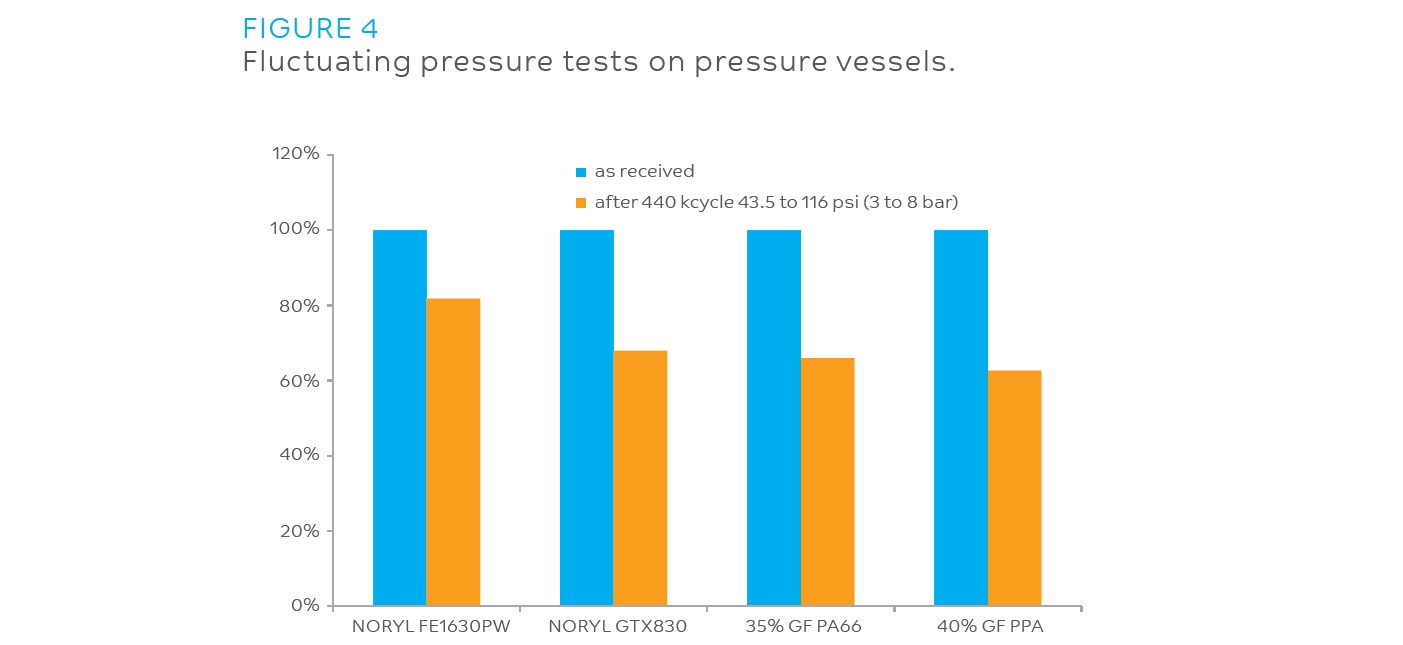

NORYL resin is more stable under cyclic pressure over several cycles than competitive PA and PPA materials.

HOT WATER SYSTEMS

Traditionally, hot water systems such as boilers require many assembled metal parts to function. The growing use of engineering plastics allows manufacturers to produce boilers with fewer parts, reducing system costs and enabling higher operating efficiency.

HEAT EXCHANGERS

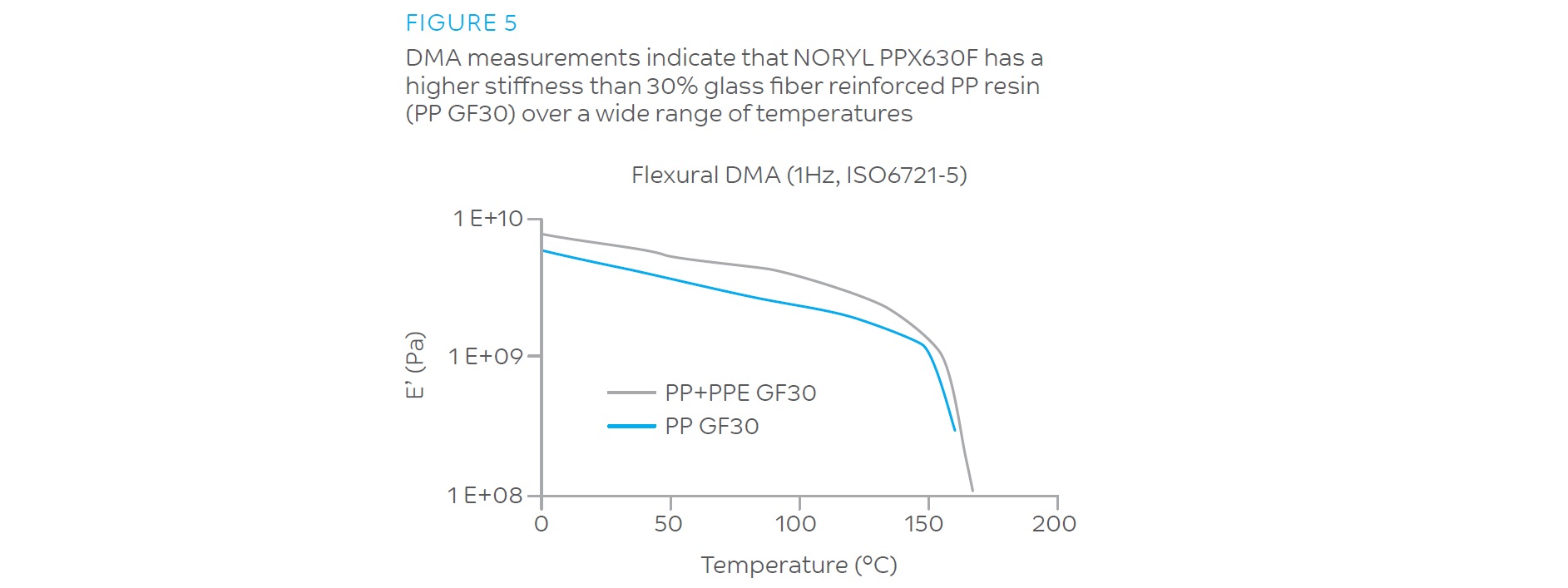

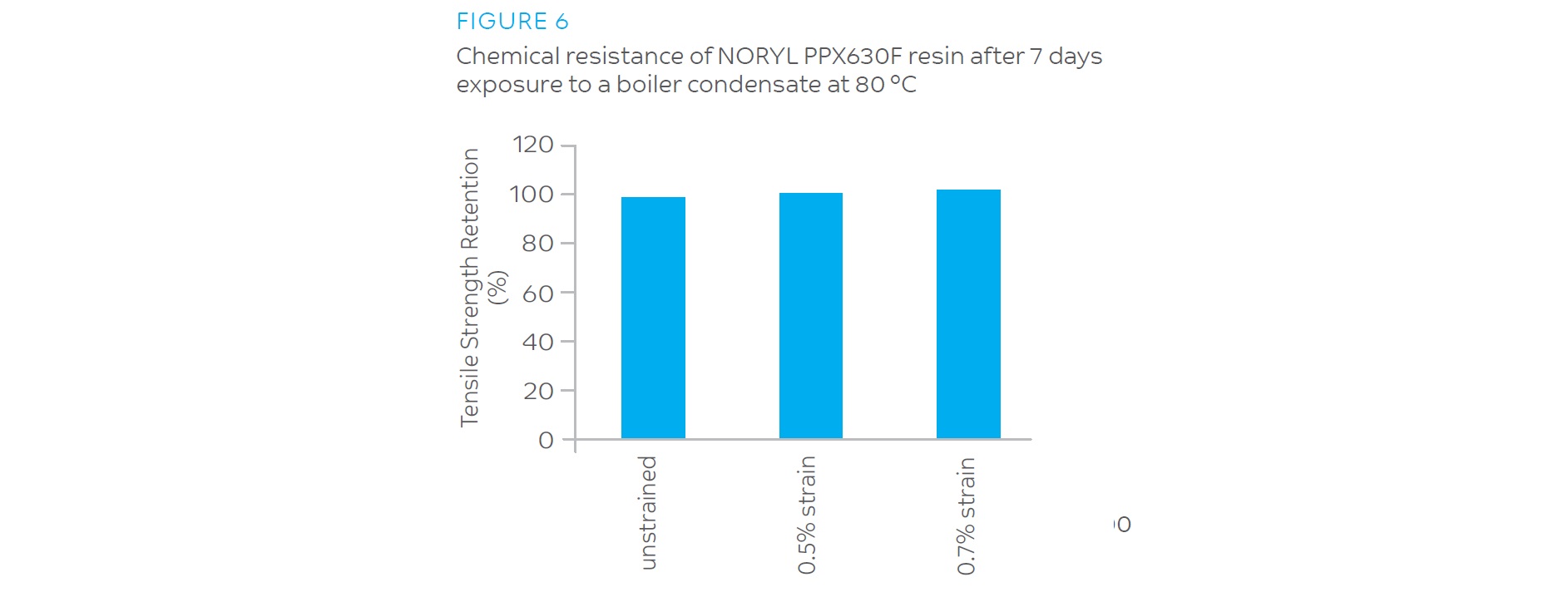

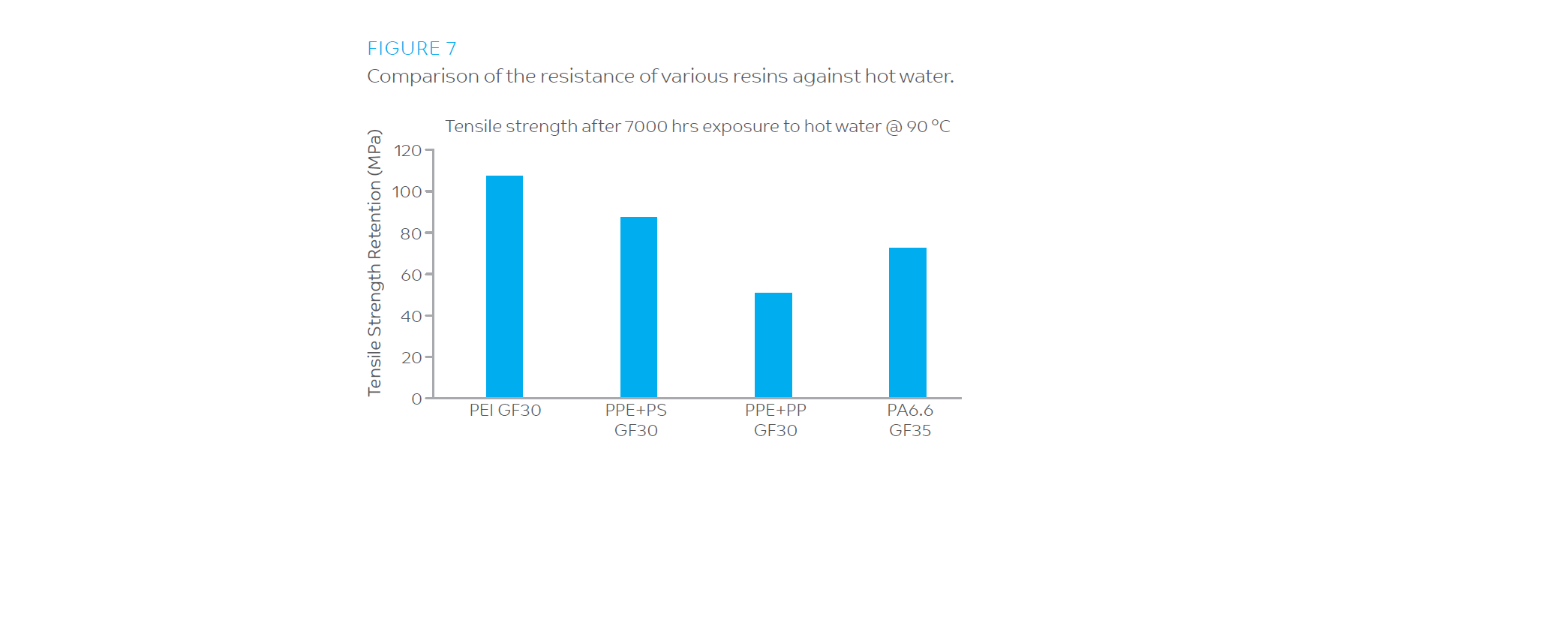

With its excellent balance of heat resistance, resistance to condensates and fumes, mechanical performance and dimensional stability, NORYL PPX™ 630F resin is a superb candidate resin for parts such as condensing heat exchangers. Typically, glass-filled polyamide (PA) resins exhibit the required heat resistance but lack the chemical resistance—which is needed as the condensate in the boiler is very acidic - pH2-3. Glass fiber reinforced polypropylene resin typically shows good resistance to acidic condensates, but lacks sufficient heat resistance as shown in Figure 5. NORYL PPX, a PPE-PP blend, offers both heat and chemical resistance, as seen from its exposure to boiler condensate shown in Figure 6.

The combination of easy part consolidation and the inherent light weight of NORYL PPX resin offers manufacturers the possibility to reduce boiler dimensions by up 30% and total weight by up to 15%. This can provide easier handling, installation and reduced maintenance costs.

SERMETA France selected NORYL PPX630F resin for its heat exchanger coil housing. It was selected because of its remarkable chemical resistance, excellent heat resistance and good dimensional stability.

Remeha selected NORYL™ resin for their hydroblock water heater component for its superior hydrolytic stability in hot water.

COVERS

Engineering thermoplastics offer diverse stylistic opportunities. With large part molding experience, SABIC has demonstrated how bosses, ribs and holes can be cost-effectively integrated into a single lightweight molded part, which requires no after-treatment. Boiler covers can be molded in a wide choice of colors using materials such as CYCOLAY™ and GELOY™ resins.

MANIFOLD

Hydroblock manifolds require long-term dimensional stability and excellent chlorine resistance. Moving from brass to plastics, Remeha selected NORYL resin for its global potable water approval and outstanding performance.

SANITARY FAUCETS AND SHOWER COMPONENTS

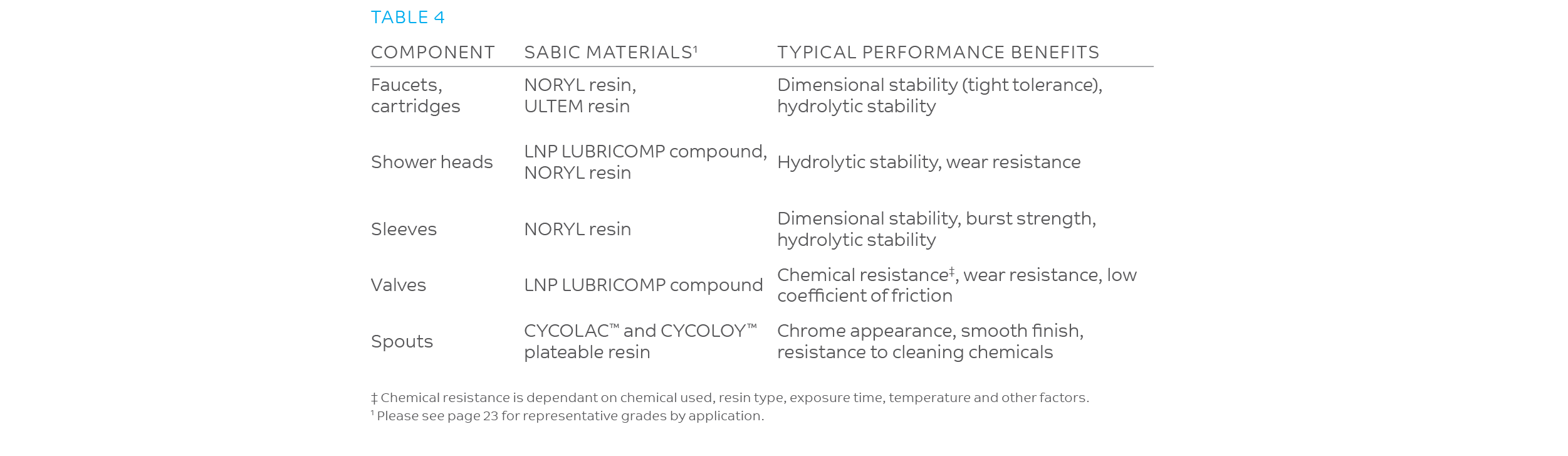

NORYL™ resin, ULTEM™ resin and LNP™ compounds can provide low cost, high performance solutions for a broad range of sanitary faucets and shower components. Compared with traditional metal assemblies, these solutions can offer raw material, manufacturing and logistics cost savings.

In addition, these corrosion free materials help reduce the problems of mineral build-up and can eliminate corrosion that interferes with the operation of metal parts and fittings. Typical parts include spray water channel inlets, thermostatic control valve housings, hot water mixing channels and shower head inlets.

NORYL resin offers outstanding hydrolytic stability, great strength and high temperature resistance.

With most of Europe and North America now requiring low-lead brass, the use of thermoplastics in parts such as cartridges is growing. Most glass-filled NORYL resins meet all NSF/ANSI 61, KTW and other EU regulations. ULTEM resins can offer additional benefits in hot water applications including superior mechanical properties and dimensional stability vs. polysulfones.

WATER SOFTENING AND FILTRATION

Water filtration and treatment is one of the most exciting areas in the industry, and innovation abounds from the system design, to equipment, and even the membrane materials. In areas such as the Southwestern United States, where hard water can cause taste and stain issues with cooking and laundry, water softening systems are an essential part of life. NORYL resin has successfully replaced steel in softening cartridge components because of its balance of cost and performance benefits. NORYL offers superior property retention and dimensional stability at elevated temperatures versus filled polypropylene.

As global access to quality drinking water supply becomes one of the most important challenges for the future, the installation of reliable and cost-effective water treatment systems becomes critical. NORYL resins have proven creep resistance and sustained performance in extended exposure to water, making them excellent candidates for reverse osmosis and other filtration technology elements. In addition, SABIC offers a range of materials to meet specific performance needs of thermostatic and mixing control valves for water treatment systems. For example, GE Osmonics developed an innovative all-plastic control valve using NORYL GFN2F resin, delivering new standards in performance and serviceability.

Russian manufacturer Aquaphor selected NORYL resin for their whole-home filtration elements. They were able to design with thinner walls versus polyamide, and, due to NORYL resin’s long term hot water stability, Aquaphor was able to offer a longer warranty to their customers.

PIPES AND FITTINGS

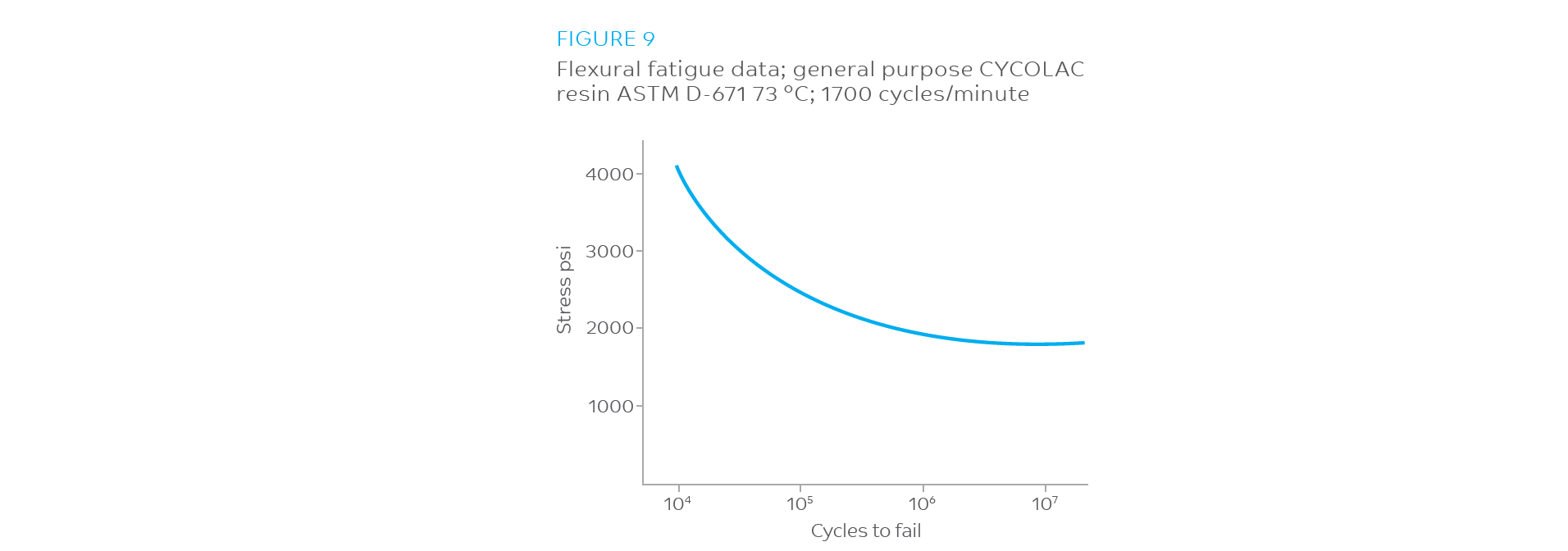

Water distribution and industrial piping systems demand materials that can withstand extreme environments over a very long product lifetime. CYCOLAC™resin is a well established material in this area, providing reliable piping for various industries around the world.

CYCOLAC resin combines toughness and durability, maintaining its high performance over a wide range of temperatures and pressures. Furthermore, it provides good extrudability and quick on-site jointing, making CYCOLAC resin a good candidate for low pressure piping.

Piedmont Pacific, a leader in specialty couplings, designed a low-pressure grooved-end flexible pipe coupling using NORYL™ resin. NORYL resin is resistant to corrosion, a primary concern in brackish and seawater reverse osmosis systems, and is lightweight and stable in wet, outdoor environments.

THE CUSTOMER INNOVATION PROCESS

INTRODUCTION

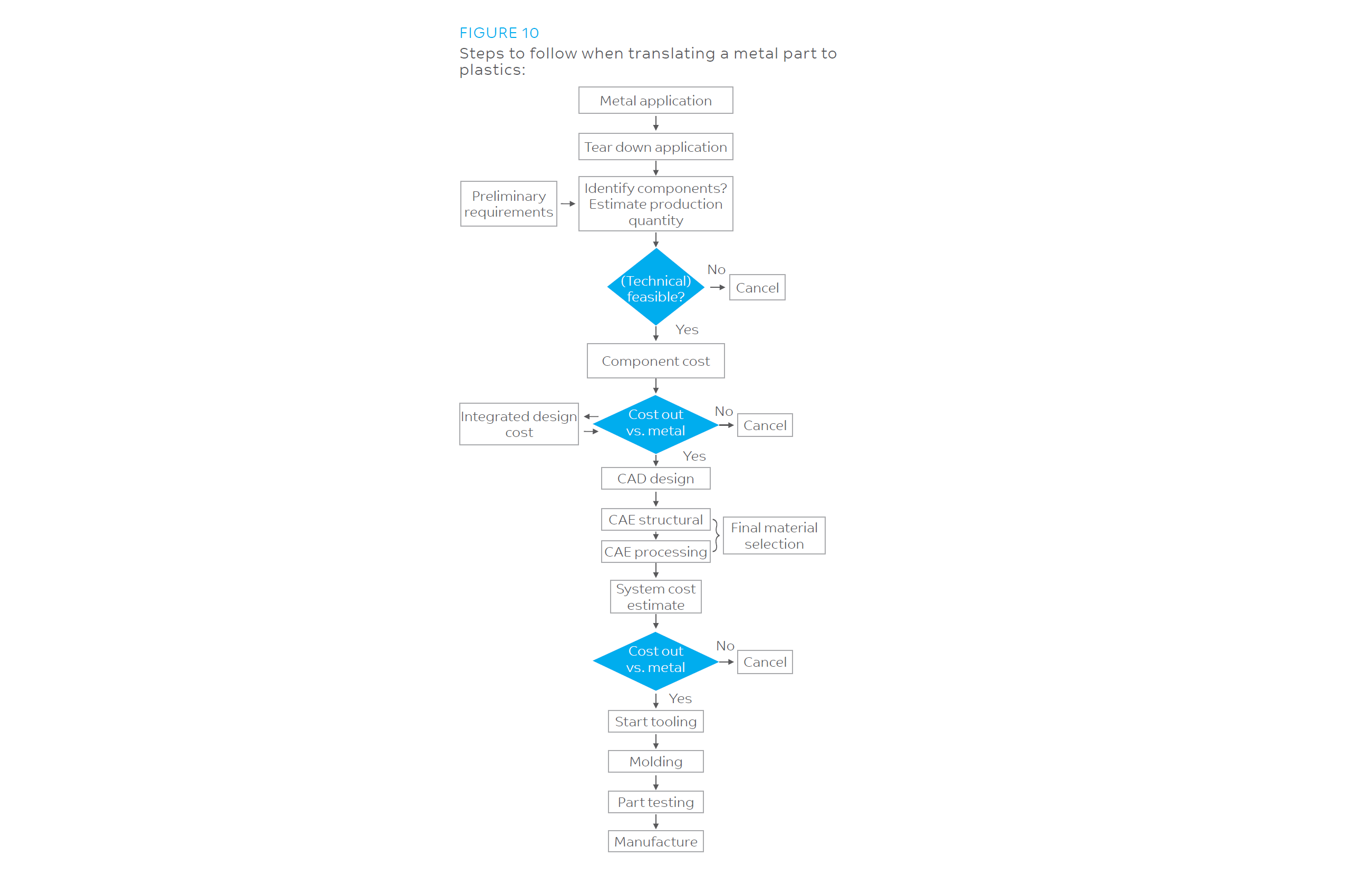

From concept generation through the many development stages to industrialization, SABIC supports its customers from start to finish:

- Initial concept to meet specific industry criteria

- Design assistance using dedicated engineering design services

- Material selection assistance to meet performance criteria and industry standards

- Advanced predictive engineering

- CAD/CAE analysis

- Processing evaluation in state of the art laboratories

- Secondary operations evaluation

- Prototyping

With this unique level of technical support, SABIC is helping customers around the world to be on the cutting edge of design. From submersible pump housings to condensing heat exchangers, reverse osmosis components to state of the art solar panels, SABIC is willing and able to help customers develop their next generation fluid handling applications.

When this process involves metal to plastics conversion, SABIC can assist using a structured approach, which starts with design evaluation and leads to enhanced system efficiency through part integration, elimination of secondary operations, weight reduction and ease of assembly.

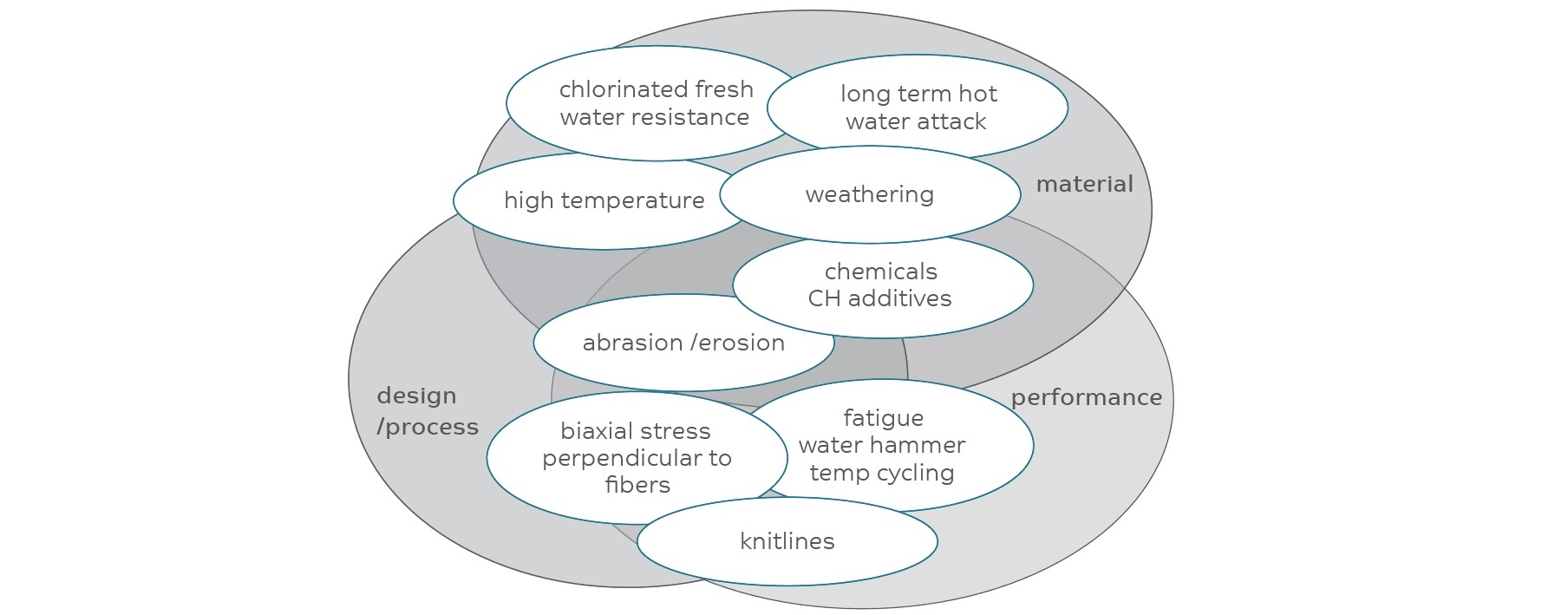

END USE REQUIREMENTS

Components exposed to water have high performance requirements since water is, in fact, a harsh chemical over time. In addition to satisfying any regulatory requirements, the design must meet the environmental and physical use demands, as well as the practical factors of manufacture and assembly.

This critical phase in the design process should include the consideration of a number of different performance requirements, including these listed below:

- Ensure the part is designed strong enough to withstand short term loads, such as an internal pressure peak.

- Very long exposure to constant stress may cause a part to change dimensions as a result of “creep.”

- In fluctuating pressure environments, a material with strong fatigue resistance should be selected.

- Use caution when the thermal expansion of one component differs from the thermal expansion of the component against which it is mounted, such as thermoplastics on steel. Both constant and fluctuating temperatures may impact this part’s performance.

- During both assembly and use, it is essential to avoid environmental stress cracking due to a material being sensitive to chemicals.

- Abrasion between moving parts or erosion caused by abrasive particles in the fluid can cause wear. Wear can also result from surface fatigue if surface stress exceeds the endurance limit of the material.

- Knit lines at openings are often sources of weakness.

AGENCY APPROVALS

For water applications, SABIC offers materials which meet or exceed the stringent regulations for food and water contact by the EU and the FDA. In the USA, potable water materials are required to meet NSF 61. For non-potable water applications, there are various other NSF listings which may need to be considered for material and product approval.

In Europe, SABIC certifies its materials to meet national requirements for potable water in Germany (KTW and W270), France (ACS) and the UK (WRAS).

The new food contact requirements enacted by the European Union (EU), applicable beginning January 2016, change the types of glass additives for polymers that are allowed to be in contact with food. SABIC’s NORYL™ potable water resin series is a unique solution, certified to meet both the EU January 2016 food contact requirements and the country-specific regulations for potable water.

Please learn more about the NORYL potable water series at our website, www.sabic.com.

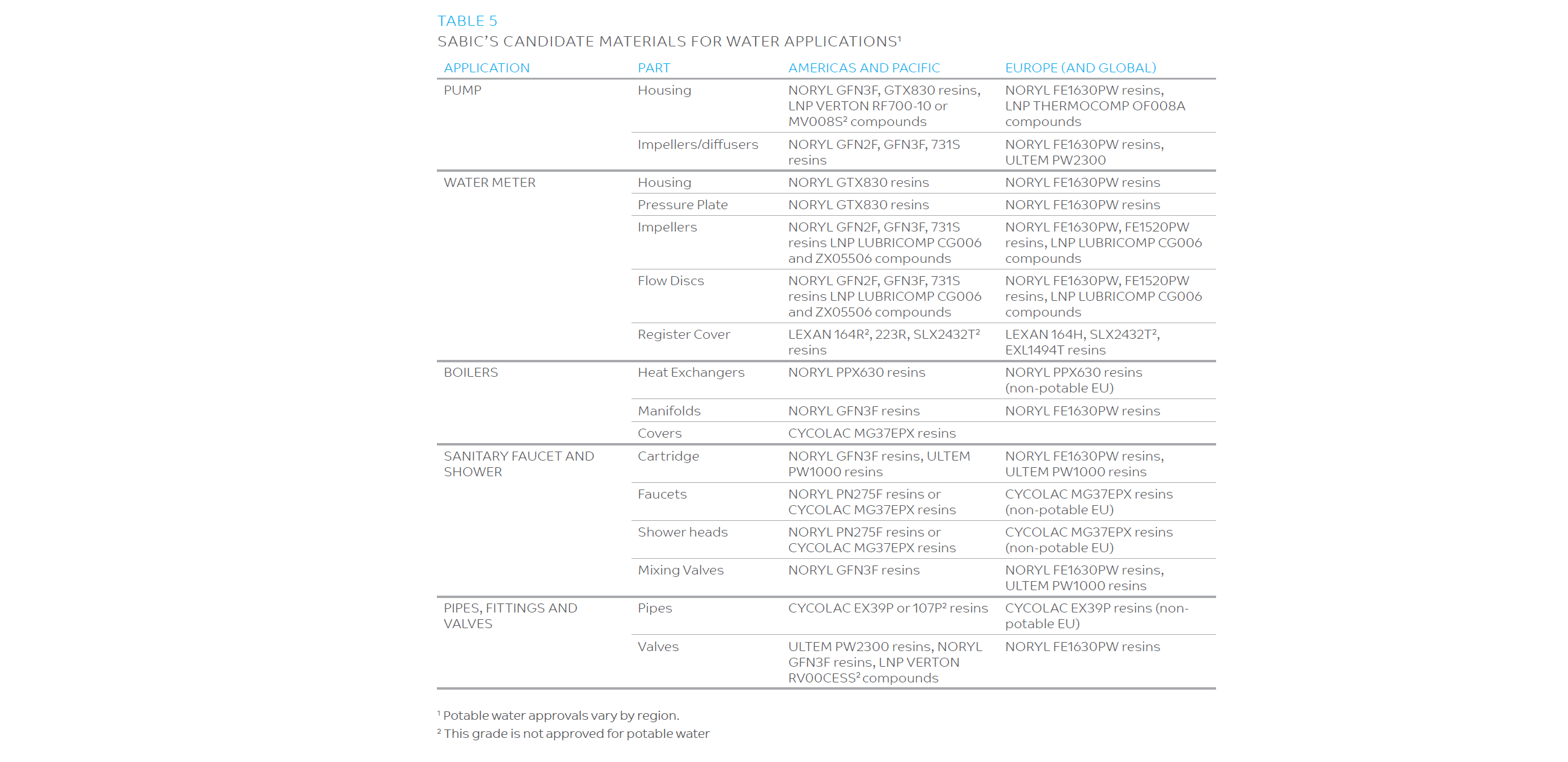

APPLICATION GRADES OVERVIEW

The materials described in the table below are intended to provide an overview of SABIC’s solutions that are frequently chosen for certain water applications. However, customized solutions are commonly required in this industry to optimize performance of parts in a specific water quality or mechanical environment. SABIC leverages our base chemistry, design expertise and historical success in water applications to help our customers engineer parts to their exact requirements. Please work with your SABIC commercial and technical support teams and visit our extensive product/process knowledge base at www.sabic.com for more information

SABIC offers a variety of NORYL™, ULTEM™, CYCOLAC™ and LEXAN™ resins, in addition to LNP™ compounds, for a number of different water management applications.

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

THE MATERIALS, PRODUCTS AND SERVICES OF SAUDI BASIC INDUSTRIES CORPORATION (SABIC) OR ITS SUBSIDIARIES OR AFFILIATE S (“SELLER”) ARE SOLD SUBJECT TO SELLER’S STANDARD CONDITIONS OF SALE, WHICH ARE AVAILABLE UPON REQUEST. INFORMATION AND RECOMMENDATIONS CONTAINED IN THIS DOCUMENT ARE GIVEN IN GOOD FAITH. HOWEVER, SELLER MAKES NO EXP RESS OR IMPLIED REPRESENTATION, WARRANTY OR GUARANTEE ( i ) THAT ANY RESULTS DESCRIBED IN THIS DOCUMENT WILL BE OBTAINED UNDER END USE CONDITIONS, OR (ii) AS TO THE EFFECTIVENESS OR SAFETY OF ANY DESIGN OR APPLICATION INCORPORATING SELLER’S MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS. UNLESS OTHERWISE PROVIDED IN SELLER’S STANDARD CONDITIONS OF SALE, SELLER SHALL NOT BE RESPONSIBLE FOR ANY LOSS RESULTING FROM ANY USE OF ITS MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS DESCRIBED IN THIS DOCUMENT. Each user is responsible for making its own determination as to the suitability of Seller’s materials, products, services or recommendations for the user’s particular use through appropriate end use and other testing and analysis. Nothing in any document or oral statement shall be deemed to alter or waive any provision of Seller’s Standard Condit ions of Sale or this Disclaimer, unless it is specifically agreed to in a writing signed by Seller. Statements by Seller concerning a possible use of any material, product, service or design do not, are not intended to, and should not be construed to grant any license under any patent or other intellectual property right of Seller or as a recommendation for the use of any material, product, service or design in a manner that infringes any patent or other intellectual property right.

SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates, unless otherwise noted.

© 2023 Saudi Basic Industries Corporation (SABIC). All Rights Reserved.

Any brands, products or services of other companies referenced in this document are the trademarks, service marks and/or trade names of their respective holders.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience