SABIC SOLUTIONS IN ENERGY GENERATION AND STORAGE APPLICATIONS

SABIC

Founded in 1976, SABIC is the first public, global multinational enterprise headquartered in the Middle East. Our products range from bulk commodity chemicals to highly engineered plastics for demanding applications. We are a leading producer of polyethylene, polypropylene, glycols, methanol and fertilizers and a global leader in the production of polyolefins.

SABIC’s offerings include Chemicals, Polymers, Specialties, Agri-Nutrients and Metals. In Saudi Arabia, the Netherlands, Spain, the USA, India, China and Japan, our dedicated Technology & Innovation centers research ways to meet our customers’ needs with excellence.

INNOVATING FOR CUSTOMER SUCCESS

We believe that SABIC customers deserve the full benefit of every advantage our enterprise can offer. After all, our success is defined by our customers’ success. And with more than 80 years of experience pioneering advanced engineering thermoplastics, SABIC is positioned to help create new opportunities for growth and breakthrough applications.

We offer expertise and experience to our customers in a variety of ways:

• Material solutions to help drive innovation and market leadership.

• Design, logistics and processing expertise to spark new ideas and better efficiencies.

• Unwavering commitment to build long-term relationships with ingenuity, trust and continuous improvement.

It’s what we strive for and work to deliver… a mutual benefit. Excellence and nothing less.

WIND: SUSTAINABLE FUTURE

SABIC’s Specialties Business offers a broad portfolio of thermoplastic materials, potentially suitable for wind turbine applications. The use of thermoplastics may help decrease part system cost but also enable recyclability of components closing the loop.

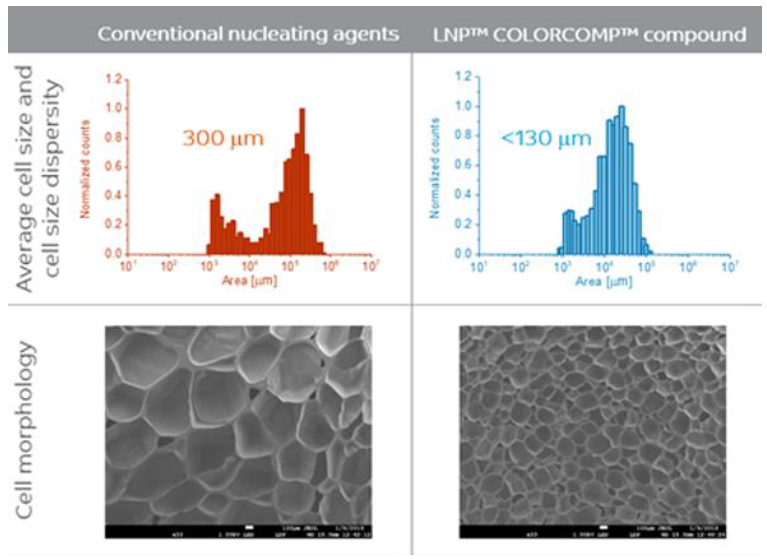

LNP™ COLORCOMP™ WQ117945 compound is a material based on nanotechnology that facilitates production of polyethylene terephthalate (PET) foams with smaller cell sizes for core materials in sandwich structures.

This new compound improves control over nucleation and cell growth, resulting in decreased cell size and uniform, narrower cell size distribution. These attributes can reduce the foam’s weight by minimizing resin uptake in sandwich structures significantly decreasing infusion density. It can also potentially improve shear strength/strain properties for better fatigue performance.

Another example is using ULTEM™ resin as epoxy replacement in many turbine electrical generation applications. Bus bar separators produced with ULTEM resin using injection molding technology may improve productivity, reduce system cost and improves sustainability.

ULTEM resin in bus bar separator application

Promoting fine nucleation in PET foam extrusion process, LNP COLORCOMP WQ117945 compound may reduce infused blade core density.

SOLAR: A RAPIDLY EVOLVING INDUSTRY

The solar industry is rapidly evolving to meet the efficiency and installed cost goals required for increased adoption.

Trend Toward Improved Tracking Materials

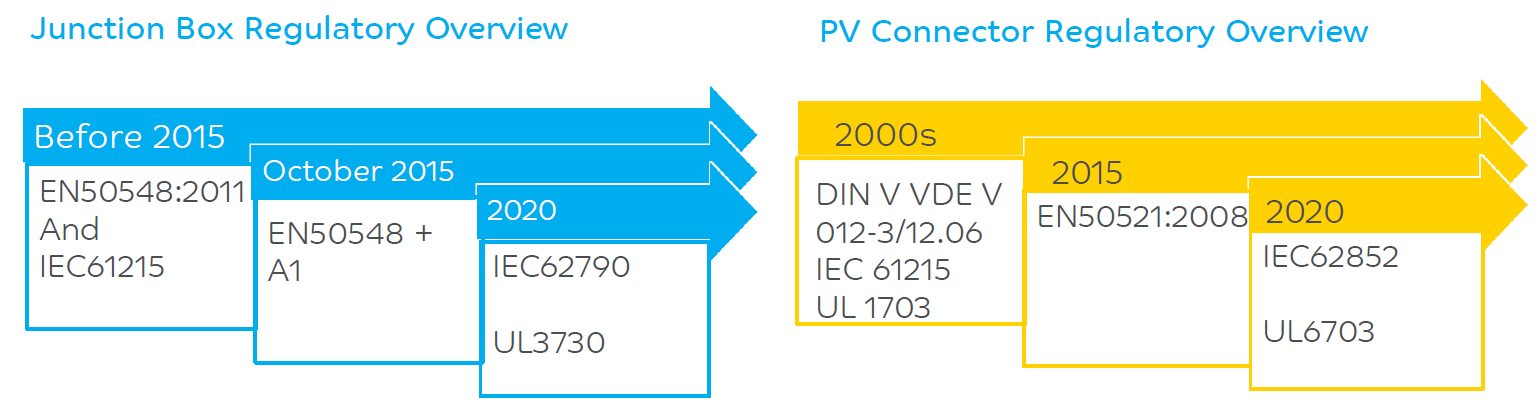

As solar energy becomes more mature and efficient, systems are being designed to handle higher voltage and storage needs. Higher performance also drives changing regulatory requirements for both PV junction boxes and connectors. Emerging standards for each component at higher voltages (1.5kV) are converging toward CTI (Comparative Tracking Index) materials capable of meeting Performance Level 0 requirements in multiple system components.

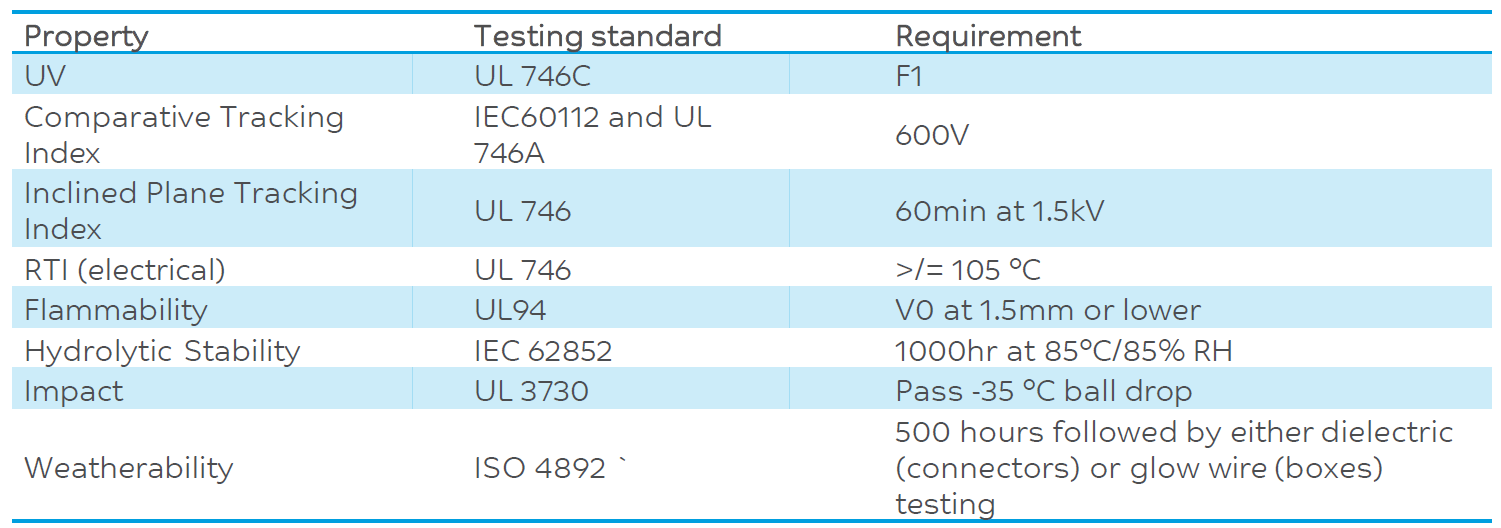

For example, junction box regulations are currently guided by IEC 62790, which steer towards CTI 0 materials at higher voltages. The same can be said of the current PV connector regulatory guidance of IEC62852. In addition to CTI, other typical performance parameters for materials used in junction boxes and connectors are shown below.

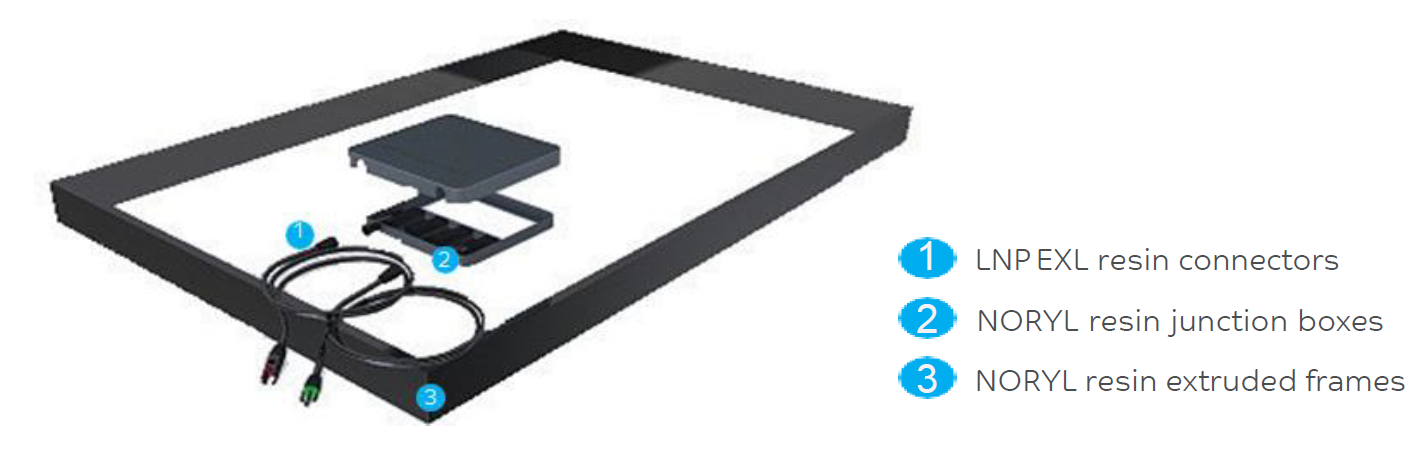

SABIC Solutions Well-Suited for PV Junction Boxes and Connectors

NORYL™ and LNP products offer performance attributes that may meet or exceed many of these regulatory, electrical and weatherability requirements.

Typical Application Requirements for PV Junction Boxes and Connectors

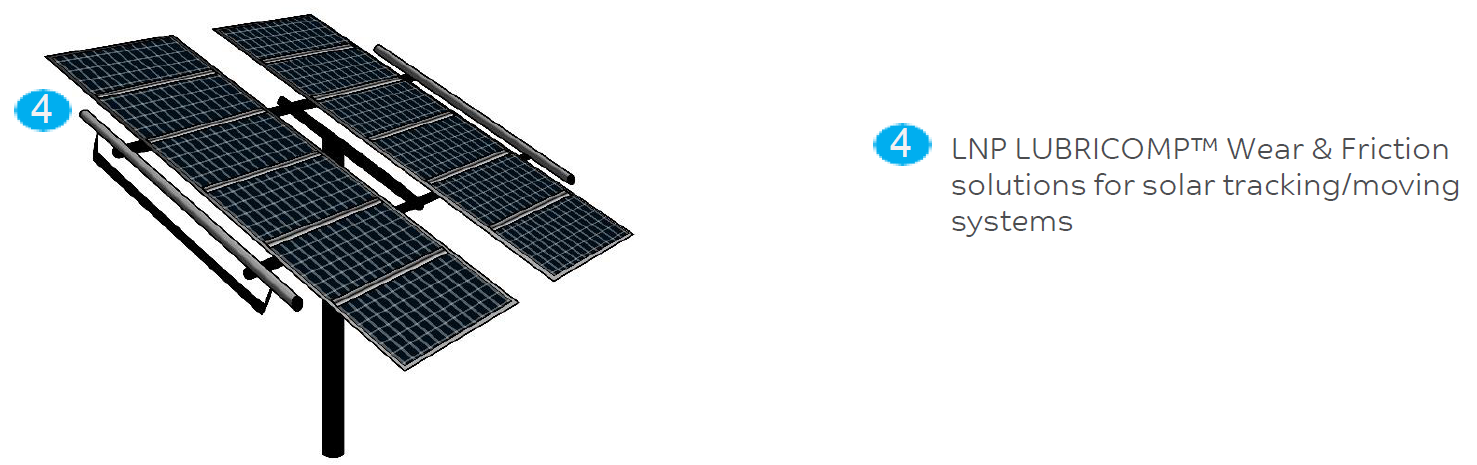

LNP COMPOUNDS WEAR AND FRICTION SOLUTIONS LUBRILOY ALLOY TECHNOLOGY

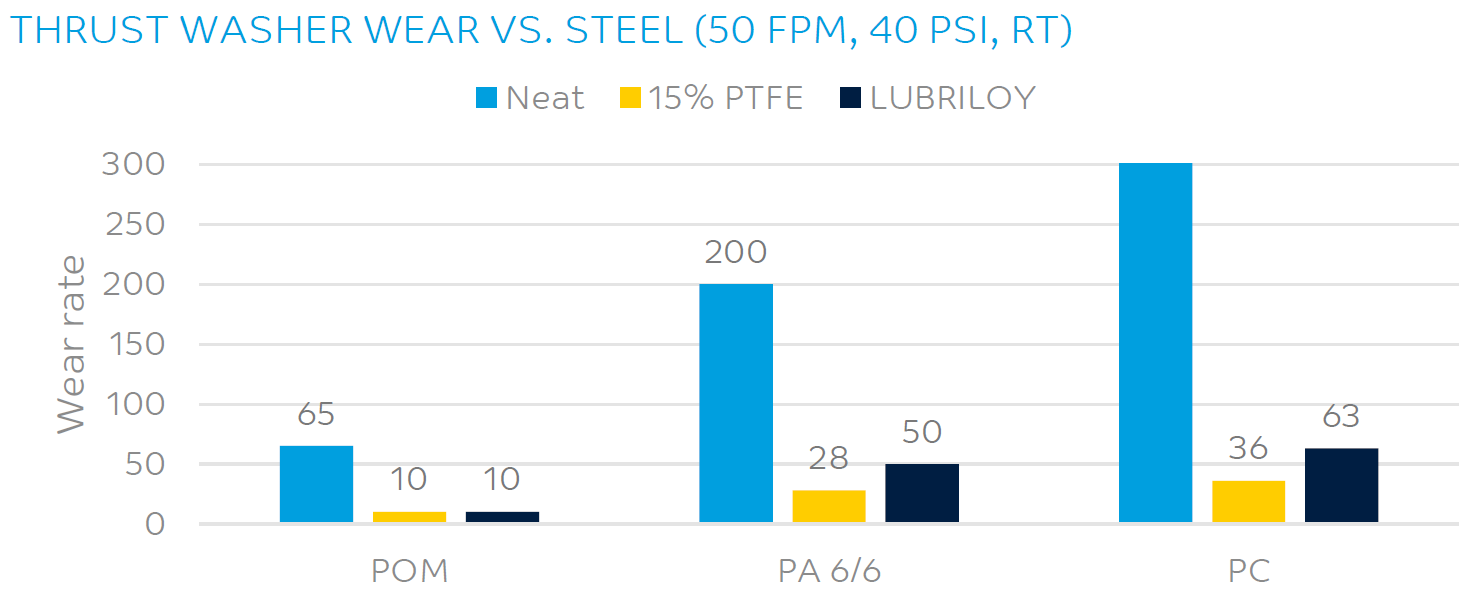

The LNP LUBRICOMP composites were among the first to offer wear and friction performance in a fully compounded, internally lubricated thermoplastic. In 1994, SABIC introduced the first in a series of LUBRILOY products, a patented lubricant technology. This extraordinary technology offers cost effective wear and friction performance vs. traditional lubricants like PTFE.

Since 1994, SABIC has expanded this technology to commonly-used resins such as polycarbonate, PC/ABS, nylon, acetal, PPA, PPO and in 2023 additional grades based on other polymers will become available. Reinforcements can also be added such as glass, aramid, or carbon fiber to enhance abrasion resistance, mechanical strength and conductivity.

LUBRILOY COMPOUNDS FEATURE

• PTFE-free, non-halogenated lubrication

• Improved impact over PTFE filled materials

• Lower mold deposits

• Excellent surface finish & colorability

• Lower S.G. vs. PTFE filled materials

LNP EXL RESINS

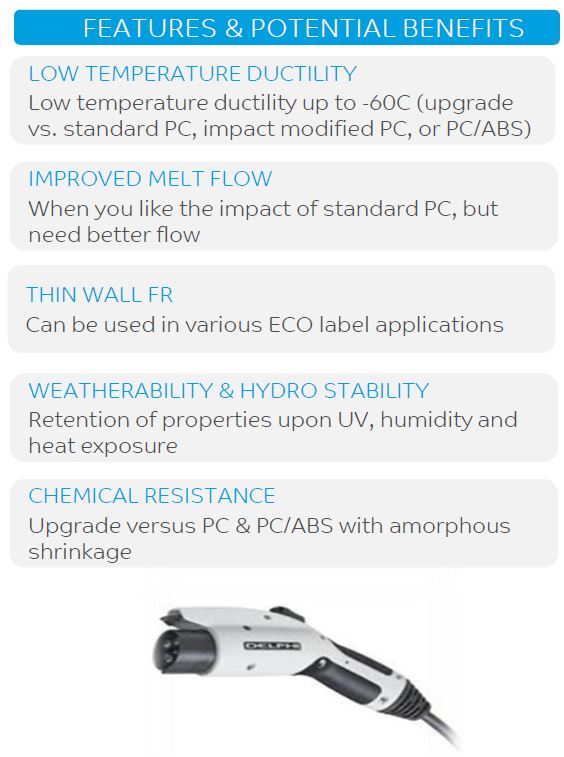

LNP EXL resin is a copolymer of polycarbonate and polysiloxane. The remarkable property profile of EXL products provides parts with outstanding impact strength and toughness over a range of temperatures, dimensional stability, consistent processability, flame retardancy, hydrolytic & chemical stability and a wide color palette.

LNP EXL9330 and LNP EXL9330S Resins

The electrical and flame-retardant performance of LNP EXL9330 and LNP EXL9330S resins help designers to miniaturize the entire and help to increase efficiency with the key feature below.

Introducing LNP ELCRESTM EXL9334P Resin

While EXL9330 resin can be used in designs requiring comparative tracking index (CTI) PLC-3 rated materials, it can suit designs that demand more stringent CTI PLC-2 properties and UL94 V0 at 0.8mm. The new ELCRES EXL9334P grade surpasses these materials in its electrical performance with a CTI PLC-0 rating (CTI=600V). Compliance with this tough standard means that EXL9334P resin is suitable for PV connectors, delivering highest CTI level to support emerging 1.5Kv systems.

It has an FR UL94 V0 rating at 1.2 mm and provides exceptional low- temperature ductility, heat resistance, good durability to chemicals and a UL746C F1 rating.

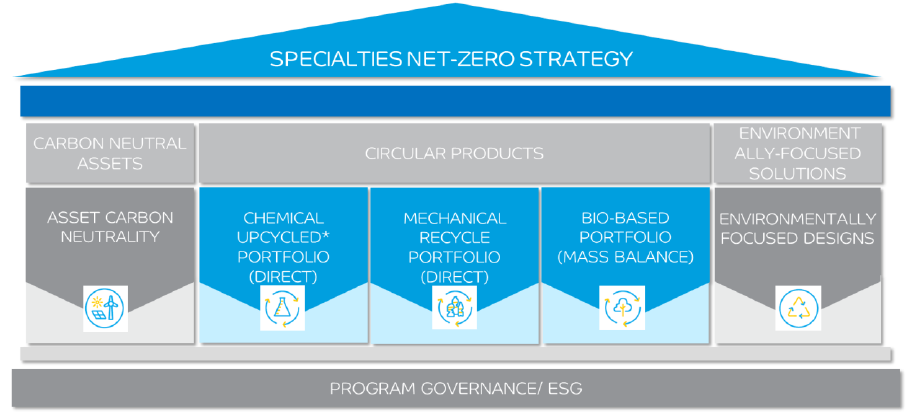

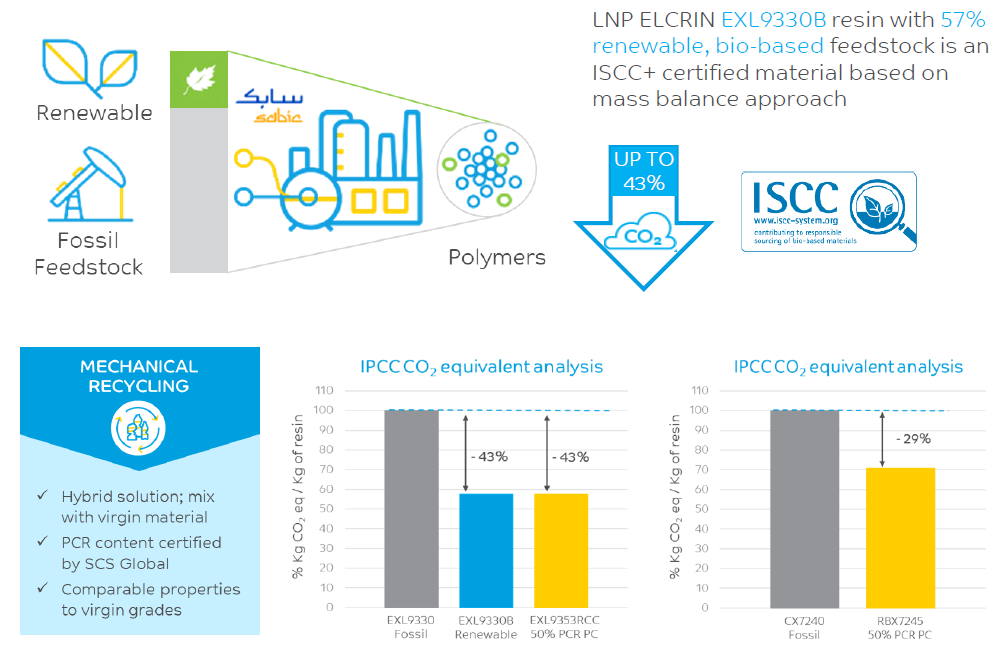

Lower CO2 footprint offerings are available though the use of PCR PC or renewable feedstock to give ISCC+ certified materials based on the mass balance approach.

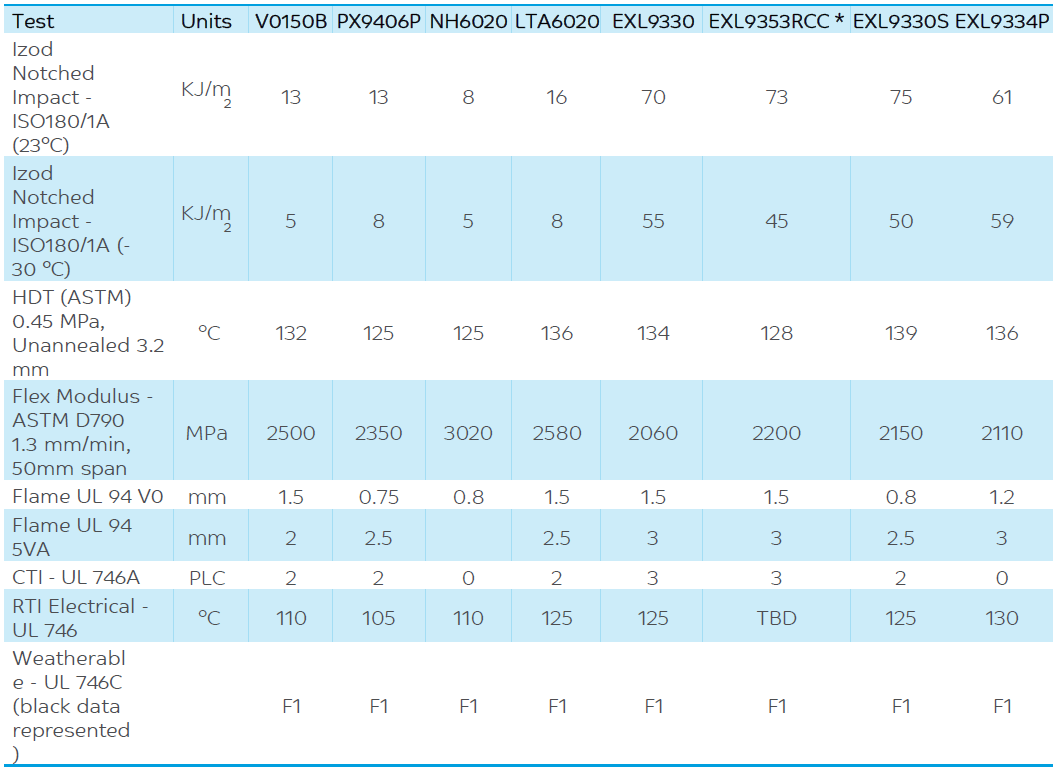

REPRESENTATIVE DATASHEET PROPERTIES FOR POTENTIAL PHOTOVOLTAIC APPLICATIONS

* LNP ELCRINTM EXL9353RCC resin is based on 50% PCR PC available in custom colors

NORYL RESINS

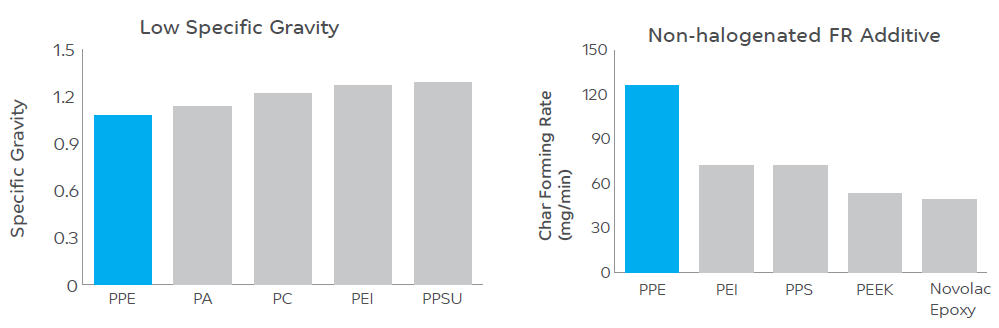

NORYL resins are built from a blend of polyphenylene ether (PPE) and polystyrene resins, along with additional additives such as glass fibers and flame retardants. NORYL resins feature industry-leading low specific gravity, moisture absorption and hydrolytic stability.

The chemistry inherent to the PPE molecules creates mechanically strong polymers and are inherently flame retardant and high heat stable, char forming, and lightweight. In addition, good resistance to typical acids and bases is a common feature of the PPE polymer and its blends with polystyrenes.

NORYL resin generally exhibits excellent electrical properties that remain stable over a wide range of temperature, humidity and frequency variations. This stability, together with a fine-tuned balance of thermal, flame retardance and impact properties, makes NORYL resin a potentially excellent candidate for demanding Energy storage, Photovoltaic, electrical and electronic applications.

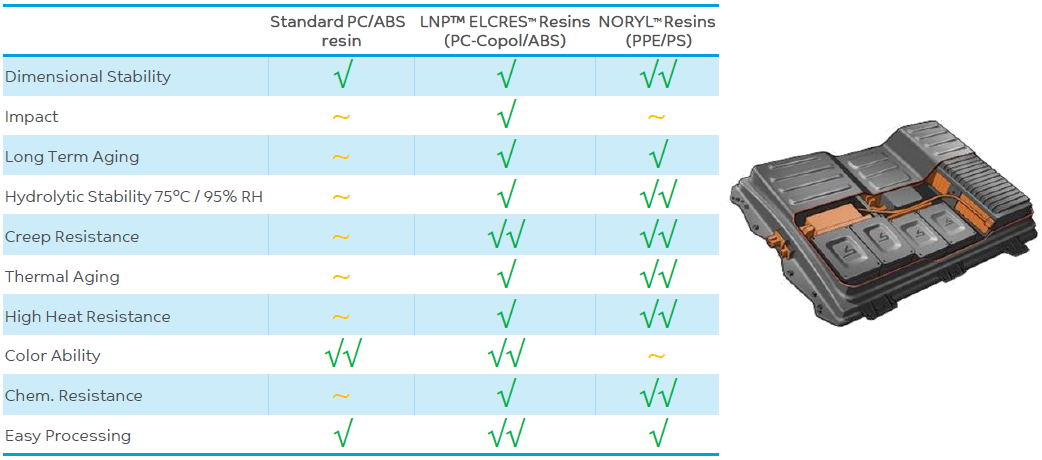

The chart on the next page shows NORYL resin’s performance capabilities and attributes compared to alternative resin solutions that may be used in Solar/Energy storage applications.

NORYL V0150B resin is a workhorse grade in solar junction boxes, offering excellent balance of properties. For thinner wall parts at similar RTI value, NORYL PX9406P resin has been successfully used. For products requiring even higher RTI values of 125°C while still maintaining CTI, NORYL LTA6020 resin can be a good candidate. NORYL SE1GFN2 resin can be positioned if higher stiffness is desired while maintaining other properties.

NORYL resin is typically the material of choice for higher temperature applications that require more fatigue durability to increased load cycling in humid environments. NORYL NH4050 resin retains most of its strength even after extended exposure to high heat and humidity.

PPE = Polyphenylene ether PC = Polycarbonate

PEI = Polyetherimide

PET = Polyethylene terephthalate PES = Polyethersulfone

PI = Polyimide

POTENTIAL SOLUTIONS FOR ENERGY STORAGE

Battery energy storage is booming to become a critical component of a decarbonized future, providing a range of home, industrial and grid-level services. SABIC’s Specialties business has been supporting segment growth of mobile and stationary lithium-ion and lead-acid battery storage for several years with material solutions for components such as small and large system housings.

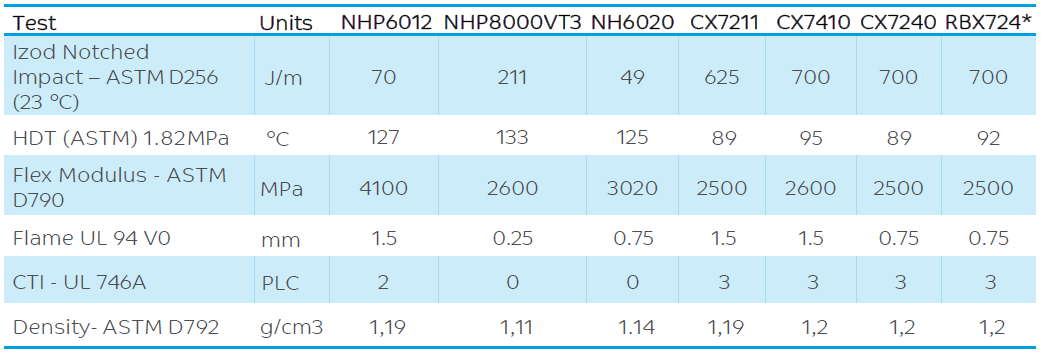

NORYL NHP portfolio of resins, based on a proprietary technology, offers a unique possibility to meet the stringent safety requirements with UL94 V0 rating down to 0.25 mm, together with good chemical resistance to battery electrolytes.

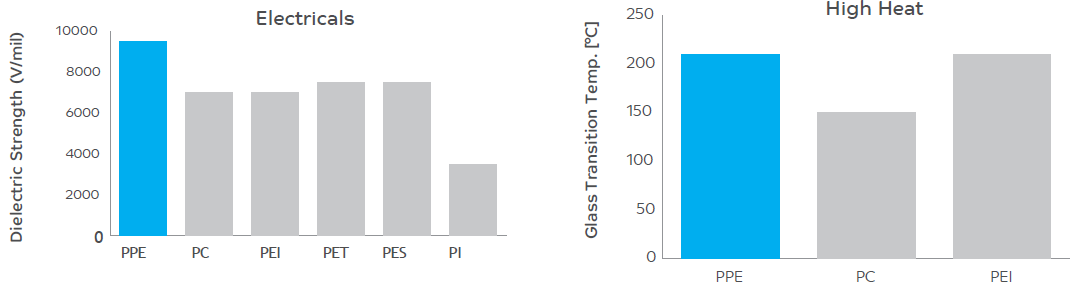

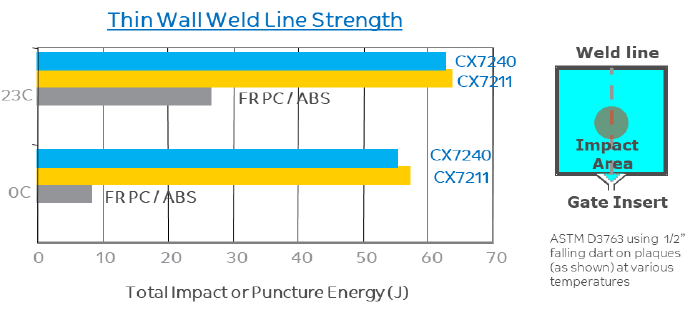

LNP CX resins are blends combining EXL copolymer resin with PC/ABS to offer improved properties such as heat/hydro and chemical durability versus standard PC/ABS blends.

These CX resins are excellent candidates for meeting thin wall FR design trends by offering all color, UL-94 V0 rating down to 0.75mm, excellent processability and release to benefit cycle times, pushing the flow-heat-impact balance to the next level. Also, conventional PC/ABS blends cannot always meet the challenges for smaller, thinner, and lighter product designs with mechanical performance. LNP CX resins can benefit weld strength compared with standard PC/ABS.

The new LNP ELCRES™ CX7410 resin is available in custom colors and shows improved heat / hydro stability, ductility at sub-ambient temperatures, chemical resistance versus CX7211 resin.

Representative data sheet properties for resins and compounds for energy storage

* LNP™ ELCRIN RBX7245 resin is based on 50% PCR PC available in dark colors

BATTERY CASES

SABIC has served the global battery market for many years with solutions ranging from LNP ELCRES™ CX resin (PC-Copolymer/ABS) to NORYL (PPE/PS) resin.

Highly differentiated flame-retardant material solutions from our LNP PC COPOLYMER blends and NORYL resin portfolio can support emerging industry requirements such as increased heat resistance (> 90°C HDT) and enhanced processability helping to achieve larger, more complex part designs. Enhanced dimensional and mechanical stability at elevated temperatures paired with improved stability against acids and resistance to hydrolysis can help extend the lifetime of battery systems, especially where thin wall sections are employed. With the emerging Redox flow and Alkaline batteries, SABIC has been actively involved providing material solutions.

SABIC material solutions provide robust flame-retardant performance even down V0 to 0.25mm that help meet the stringent safety requirements on safety such as fire exposure tests. The resins also provide high CTI rating allowing for the miniaturization of the parts. In line with global environmental targets, several sustainable material offerings are available including non-chlorinated (Cl) / non- brominated (Br) flame-retardant grades which are also free of antimony trioxide (ATO).

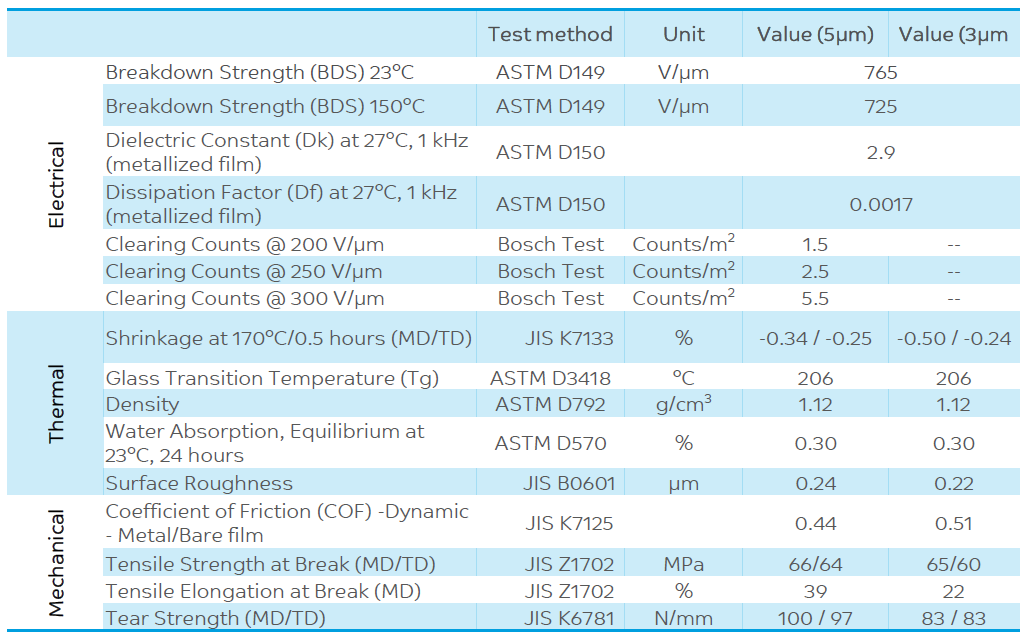

ELCRES HTV150A FILM

SABIC’s ELCRES HTV150A dielectric film offers high temperature solutions that can be used for professional grade power capacitors, addressing future high voltage industry requirements. ELCRES HTV150A dielectric film exhibits stable performance at -40°C to +150°C and frequency up to 100 kHz, including stable capacitance, good insulation resistance, stable dielectric constant (Dk) and low dissipation factor (Df). SABIC’s HTV150A dielectric film has been validated by customers with both film-foil and metalized electrodes, including flat aluminum, heavy edge/light body and fused/patterned electrode designs. ELCRES HTV150A dielectric film can be processed on existing metallization, slitting, capacitor winding and squashing/flattening equipment.

KEY FEATURES & BENEFITS

• High Dk and low Df up to 150°C and 100 kHz

• High breakdown strength from -40°C to 150°C

• Good self-healing up to 150°C

• Excellent metal adhesion (Al, Zn)

• 5 and 3 μm gauge (+/- 5% gauge uniformity)

• Empowers wide-band-gap (WBG) semiconductors

POTENTIAL APPLICATIONS

• xEV traction inverter

• xEV on board charger

• xEV electrical compressor

• Renewable energy

(wind turbines, photovoltaics)

• Mass transportation

• Motor drive and control

• Deep well drilling

TYPICAL PROPERTIES*

*These are typical properties and are not intended for specification purposes. Clearing Counts values are based on 5 µm thickness. BDS, Df, and Dk are based on 3µm thickness.

SUSTAINABLE SOLUTIONS

SABIC Specialties circular ambition is driven by the growing industry desire for sustainable solutions and fueled by our vision to compound the answer.

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

DISCLAIMER: THE MATERIALS, PRODUCTS AND SERVICES OF SAUDI BASIC INDUSTRIES CORPORATI- ON (SABIC) OR ITS SUBSIDIARIES OR AFFILIATES (“SELLER”) ARE SOLD SUBJECT TO SELLER’S STAN- DARD CONDITIONS OF SALE, WHICH ARE AVAILABLE UPON REQUEST. INFORMATION AND RECOM- MENDATIONS CONTAINED IN THIS DOCUMENT ARE GIVEN IN GOOD FAITH. HOWEVER, SELLER MAKES NO EXPRESS OR IMPLIED REPRESENTATION, WARRANTY OR GUARANTEE (i) THAT ANY RESULTS DESCRIBED IN THIS DOCUMENT WILL BE OBTAINED UNDER END-USE CONDITIONS, OR (ii) AS TO THE EFFECTIVENESS OR SAFETY OF ANY DESIGN OR APPLICATION INCORPORATING SELLER’S MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS. UNLESS OTHERWISE PROVIDED IN SELLER’S STAN- DARD CONDITIONS OF SALE, SELLER SHALL NOT BE RESPONSIBLE FOR ANY LOSS RESULTING FROM ANY USE OF ITS MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS DESCRIBED IN THIS DOCUMENT.

Each user is responsible for making its own determination as to the suitability of Seller’s materials, products, services or recommendations for the user’s particular use through appropriate end-use and other testing and analysis. Nothing in any document or oral statement shall be deemed to alter or waive any provision of Seller’s Standard Conditions of Sale or this Disclaimer, unless it is specifically agreed to in a writing signed by Seller. Statements by Seller concerning a possible use of any material, product, service or design do not, are not intended to, and should not be construed to grant any license under any patent or other intellectual property right of Seller or as a recommendation for the use of any material, product, service or design in a manner that infringes any patent or other intellectual property right.

SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates.

© 2023 Saudi Basic Industries Corporation (SABIC). All Rights Reserved.

Any brands, products or services of other companies referenced in this document are the trademarks, service marks and/or trade names of their respective holders.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience