AN INTRODUCTION OF LNP™ HIGH MODULUS DUCTILE PRODUCT PORTFOLIO

• New High Modulus Ductile Product Portfolio Introduction & Product Tree

• LNP TM THERMOTUF TM DF002PSI & DF004PSI And LNP TM THERMOCOMP TM DX10311 & DX10313 Compounds

• LNP THERMOCOMP D151 & D251 Compounds

• LNP THERMOCOMP D351, D451 & D551 Compounds

• LNP THERMOCOMP D452 Compound

• LNP THERMOCOMP DF00A1I Compound

• LNP THERMOCOMP DC0041PD, DC0041, DC0051 & DC0041PE Compound

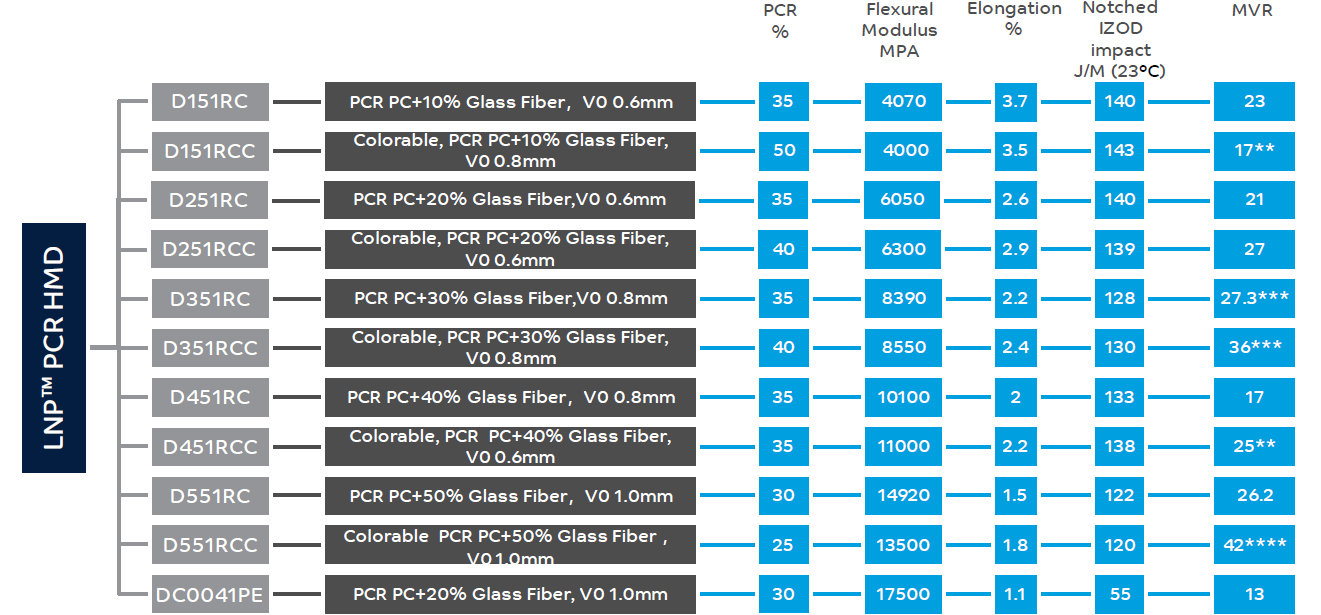

• PCR Version High Modulus Ductile Product Portfolio Introduction

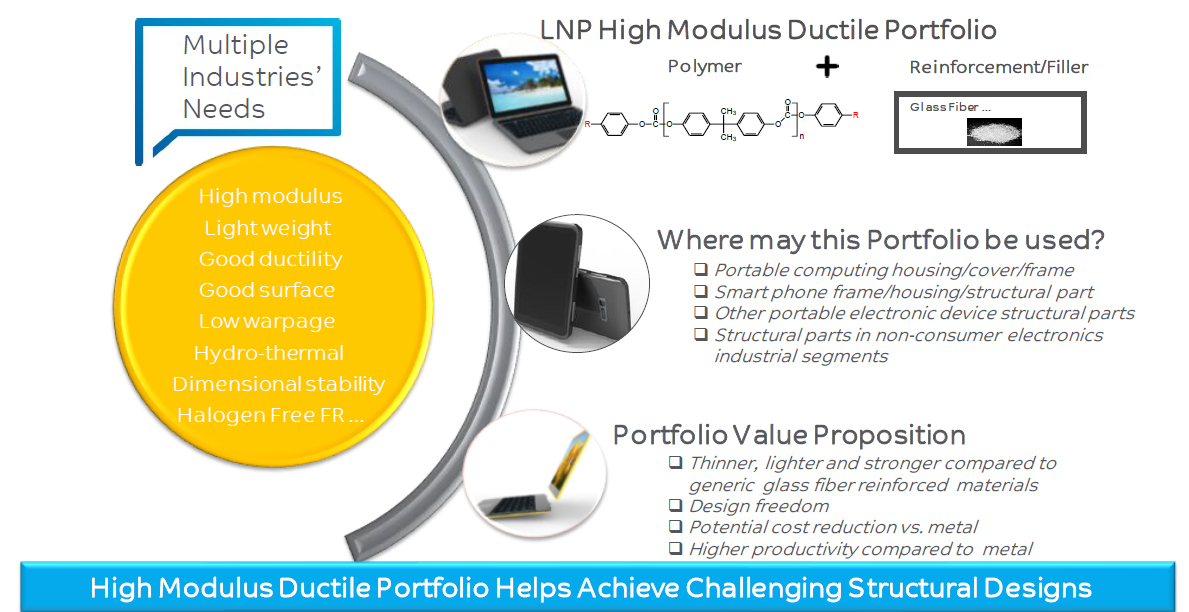

LNP™ HIGH MODULUS DUCTILE PORTFOLIO

LNP™ THERMOCOMP™ & LNP™ THERMOTUF™ HIGH MODULUS DUCTILE PORTFOLIO GRADE LIST VIRGIN VERSION

LNP™ THERMOCOMP™ HIGH MODULUS DUCTILE PORTFOLIO GRADE LIST PCR RESINS

LNP™ THERMOTUF™ DF002PSI & DF004PSI AND LNP™ THERMOCOMP™ DX10311 & DX10313 COMPOUNDS

LNP™ THERMOTUF™ DF002PSI & DF004PSI INTRODUCTION & VALUE PROPOSITION

LNP THERMOTUF DF002PSI is a 10% special glass fiber reinforced Copolymer PC base resin and non FR grade

LNP THERMOTUF DF004PSI is a 20% special glass fiber reinforced Copolymer PC base resin and non FR grade

Potential Applications

Mobile phone cover, frame, structural parts

E-book cover, frame, structural parts

Tablet cover, frame and structural parts

Other consumer electronics applications that

need high modulus

Structural parts in non-consumer electronics industrial applications that need excellent surface, outstanding 2nd operation ability, good dimensional stability and warpage control, good flow, non FR and good balance of modulus and ductility

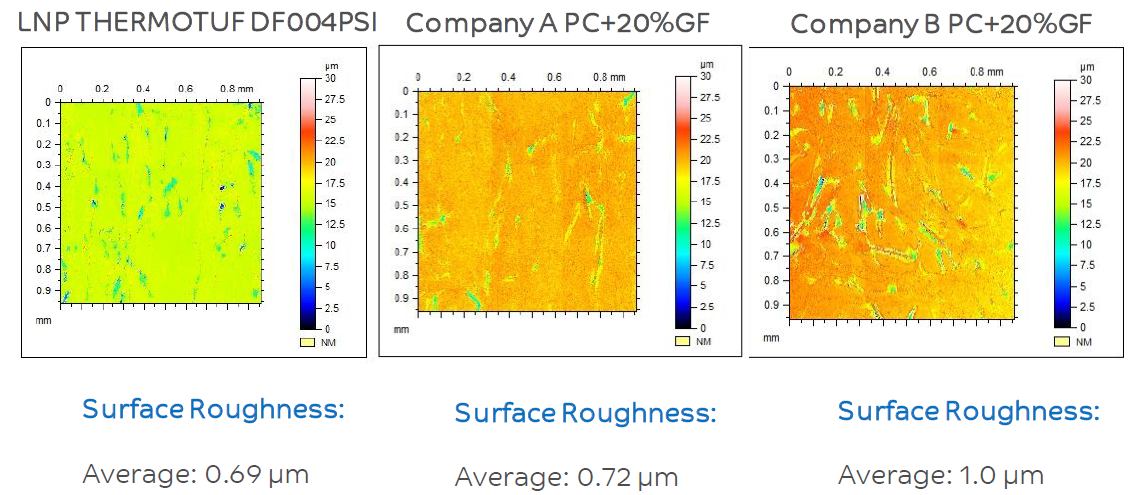

SURFACE QUALITY:

LNP™ THERMOTUF™ DF004PSI VS. OTHER COMPANIES’ PC+20%GF PRODUCTS

LNP THERMOTUF DF004PSI compound exhibits better surface quality compared with other companies’ PC+20%GF products

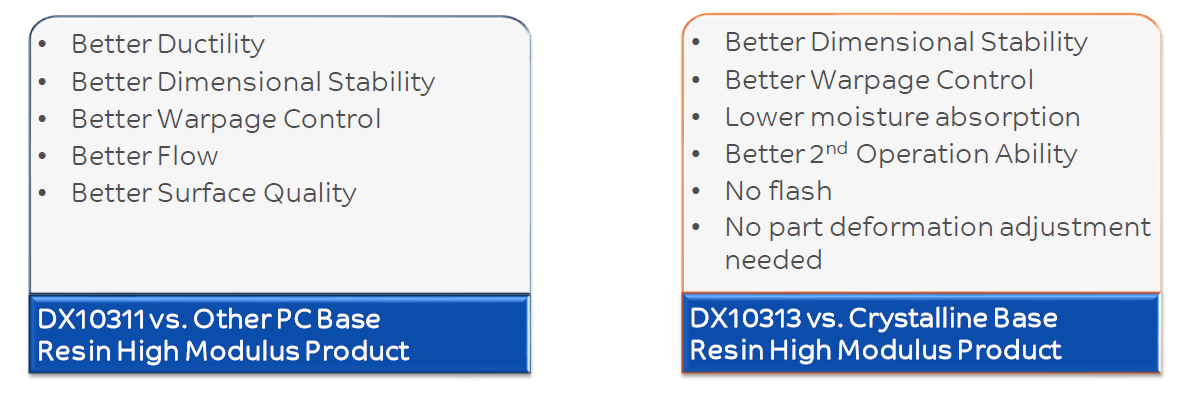

LNP™ THERMOCOMP™ DX10311 & DX10313 INTRODUCTION & VALUE PROPOSITION

DX10311 compound is a 30% glass fiber reinforced Copolymer PC base resin and non FR grade

DX10313 compound is a 50% glass fiber reinforced Copolymer PC base resin and non FR grade

Potential Applications

• MP/E-book/Tablet cover and frame and other CE applications needing high modulus ductile

• Structural parts in non CE industries requiring good dimensional stability and warpage control, good surface, non FR and good balance of high modulus and ductility

LNP™ THERMOCOMP™ D151 & D251 COMPOUNDS

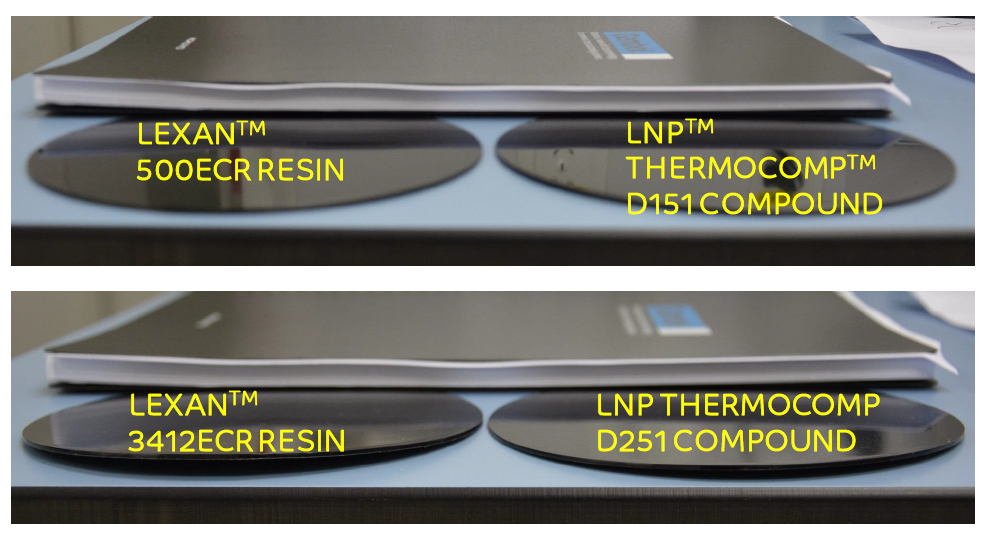

LNP™ THERMOCOMP™ D151 & D251 COMPOUNDS

LNP THERMOCOMP D151 compound is a 10% glass fiber reinforced PC based resin grade with non-brominated, non-chlorinated UL94 V0 @ 0.6mm, V2 @ 0.3mm

LNP THERMOCOMP D251 compound is a 20% glass fiber reinforced PC based resin grade with non-brominated, non -chlorinated UL94 V0 @ 0.6mm, V1 @ 0.5mm, V2 @ 0.3mm

Potential Applications

• Notebook PC, tablet, mobile phone and other consumer electronics device parts

• Structural parts in other industrial segments needing ultra thin wall FR and excellent balance of modulus, surface quality, dimensional stability, flow ability and ductility

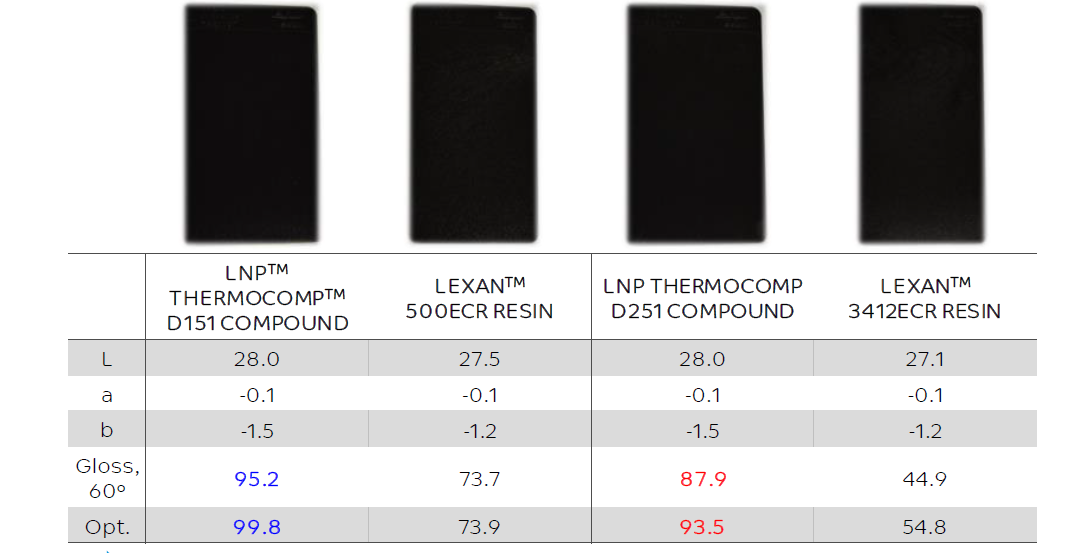

GLOSS PERFORMANCE

Can potentially achieve high gloss surface without painting

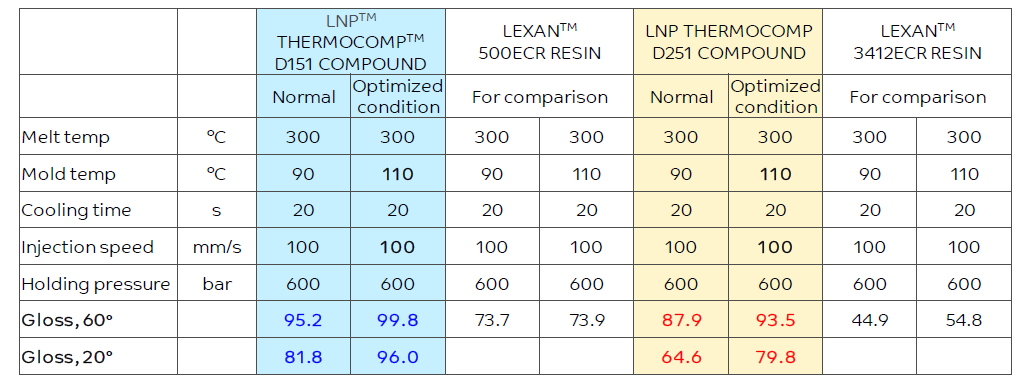

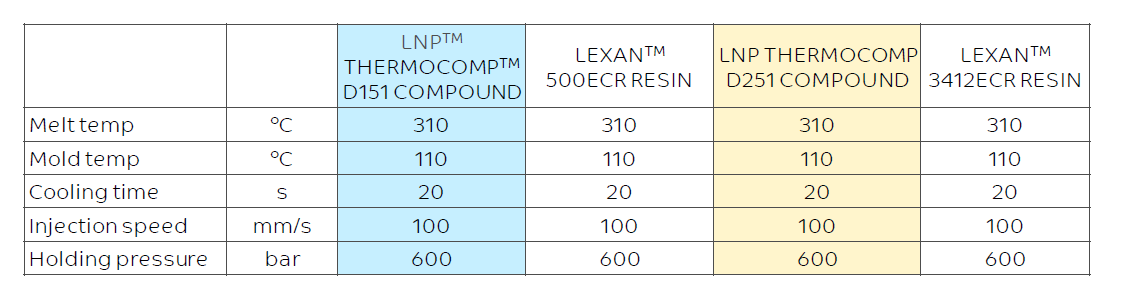

GLOSS PERFORMANCE - MOLDING CONDITION

Note:

1. Higher tool temperature = better surface

2. Higher injection speed = better surface

3. Higher melt temperature = a slightly better surface

4. Lower holding pressure will result in a slight improvement to surface

5. Cooling time of 20s is sufficient; longer cooling time does not benefit the surface.

COLOR SPACE: LNP™ THERMOCOMP™ D151 COMPOUND

Wide color space available for aesthetic design freedom

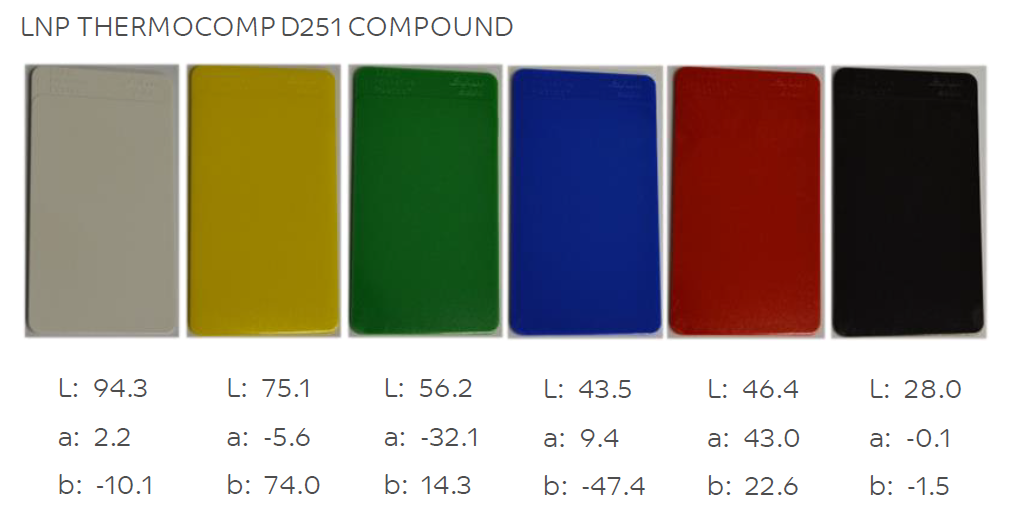

COLOR SPACE: LNP™ THERMOCOMP™ D251 COMPOUND

Wide color space available for aesthetic design freedom

WARPAGE PERFORMANCE

Improved warpage performance over previous generation products

WARPAGE PERFORMANCE - MOLDING CONDITION

Note:

1. Higher mold temperature, lower holding pressure will help to reduce the warpage.

2. Higher melt temperature, higher injection speed, longer cooling time, will induce slightly better warpage control.

LNP™ THERMOCOMP™ D351, D451 & D551 COMPOUNDS

LNP™ THERMOCOMP™ D351 D451 D551 INTRODUCTION

LNP THERMOCOMP D351 compound is a 30% glass fiber reinforced PC base resin grade with non-brominated, non-chlorinated UL94 V0 @ 0.8mm

LNP THERMOCOMP D451 compound is a 40% glass fiber reinforced PC base resin grade with non-brominated, non -chlorinated UL94 V0 @ 0.8mm

LNP THERMOCOMP D551 compound is a 50% glass fiber reinforced PC base resin grade with non-brominated, non-chlorinated UL94 V0 @ 1.0mm

Potential Applications

• Notebook PC, tablet, mobile phone and other consumer electronics device parts

• Structural parts in other industrial segments needing good dimensional stability, excellent warpage control, outstanding hydro-thermal aging stability and good balance of modulus, ductility, surface quality and thin wall FR

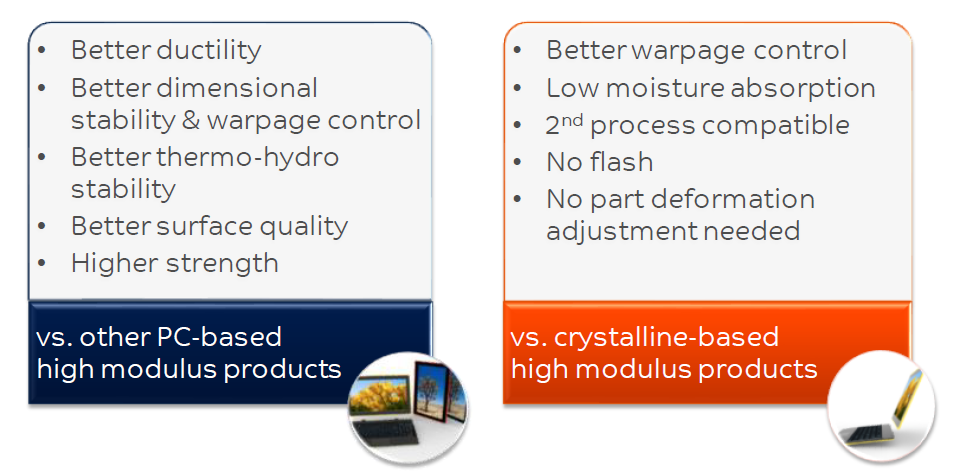

LNP™ THERMOCOMP™ HMD PORTFOLIO VALUE PROPOSITION

Win with high ductility, long term aging, dimensional stability

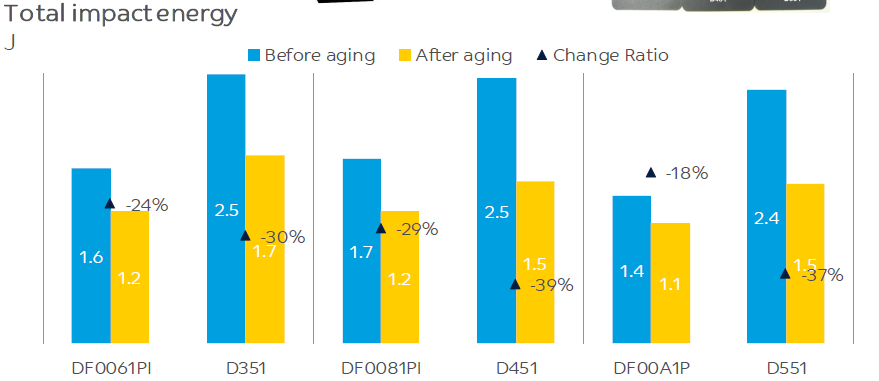

IMPACT PERFORMANCE - TOTAL IMPACT ENERGY

Test setup

• Test energy 10.00J

• Drop weight 5.06 kg

• Aging condition 75 ºC , 90%RH, 300hrs

LNP™ THERMOCOMP™ D351, D451 and D551 compounds show higher total impact energy than previous generation materials, both before and after aging

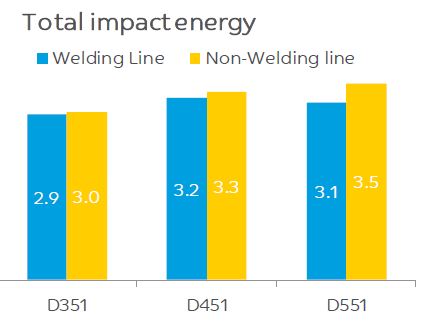

WELDING LINE - TOTAL IMPACT ENERGY

Test setup

• Test energy 10.00J

• Drop weight 5.06 kg

Results Analysis

• Similar total impact energy at welding line and non-welding line area

Similar total impact energy at welding line and non-welding line area

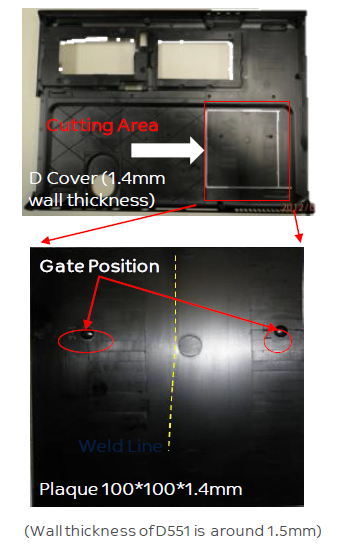

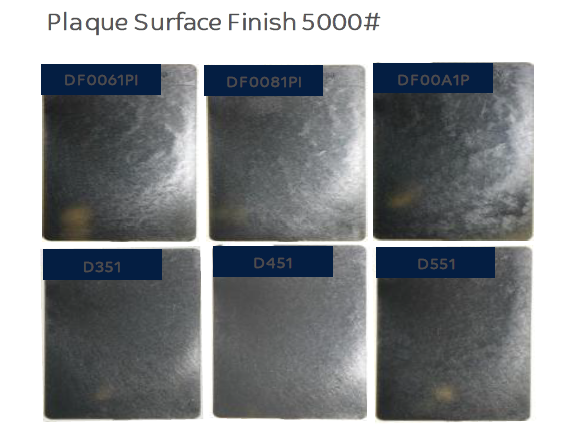

SURFACE QUALITY - FIBER FLOATING

Test Set-up

• Mold temp. 90ºC

• Plaques of various surface finish

• Visual check

• Regular injection molding condition

• LNP THERMOCOMP D351, D451 and D551 compounds show better surface quality than previous generation materials

• Texture on parts helps to cover surface defect of floating glass fibers

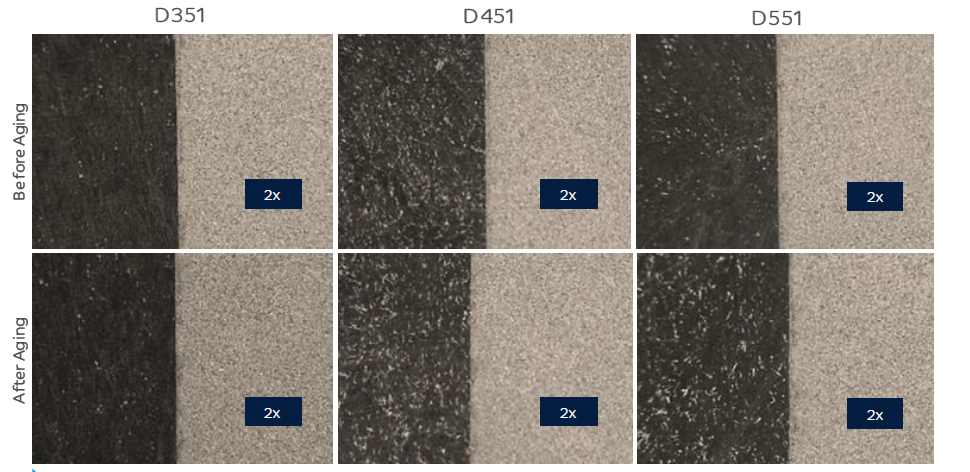

SURFACE QUALITY - SURFACE CHANGE AFTER AGING

For all three LNP™ THERMOCOMP™ compound grades, surface quality and glass fiber floating defect after aging become a little worse than before aging, but the difference is not significant (aging 75 ºC , 95%RH, 300hrs, cut from D cover)

No significant surface changes observed after aging !

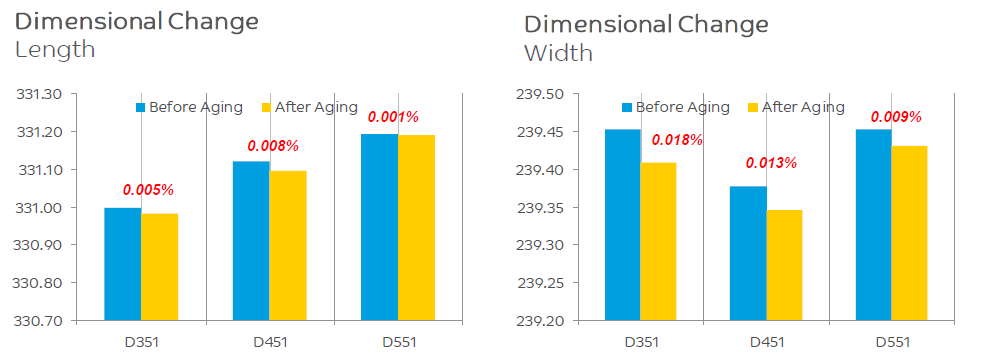

DIMENSIONAL STABILITY

Test setup

• Aging condition 300Hrs, 75 ºC , 90%RH

• CMM distance measuring machine

• Measuring position center of each boss

• D cover, 1.4mm wall thickness, length 331.4mm, width 239.6mm

LNP™ THERMOCOMP™ D351, D451 and D551 compounds show good dimensional stability after aging

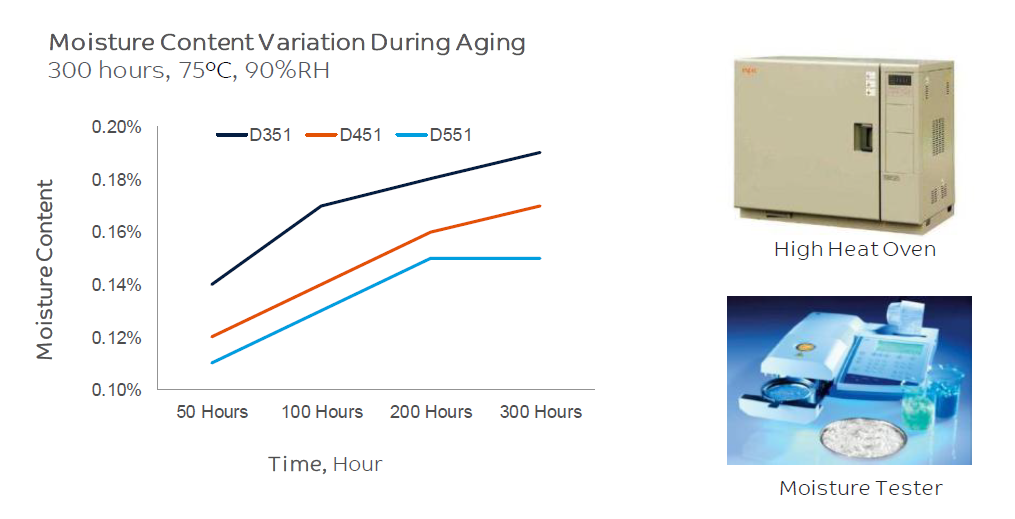

WATER ABSORPTION

LNP™ THERMOCOMP™ D351, D451 and D551 compounds approach maximum moisture content after 100~150hrs of aging

CASE STUDY - LNP TM THERMOCOMP TM D351 IN TABLET PC BACK COVER

Application: Tablet PC back cover

Application Requirements

• Non Cl, non Br FR UL94V0

• Good balance of modulus and impact for 1.0mm thickness

• Pass drop test at 75mm without cracking

• Good dimension stability, especially after painting Value Proposition By Using D351

• Higher yield rate due to better painting capability and warpage control vs. PA+50%GF

• Lower system cost vs. PA+50%GF

LNP™ THERMOCOMP™ D452 COMPOUND

LNP™ THERMOCOMP™ D452 COMPOUND

LNP THERMOCOMP D452 compound is a 40% glass fiber reinforced PC-based resin grade with super high flow and non-brominated, non-chlorinated UL94 V0 @ 1.0mm

Value Proposition

• Super high flow for IMR capability

• High modulus for thin wall applications

• Excellent impact resistance

• Excellent warpage control

• Non-Br, non-Cl thin wall flame resistance to meet UL safety requirement

• Hydro-thermal aging stability

• Good surface

Potential Applications

• Notebook PC, tablet and other consumer electronics device parts needing high flow and IMR capability

• Structural parts in other industrial segments

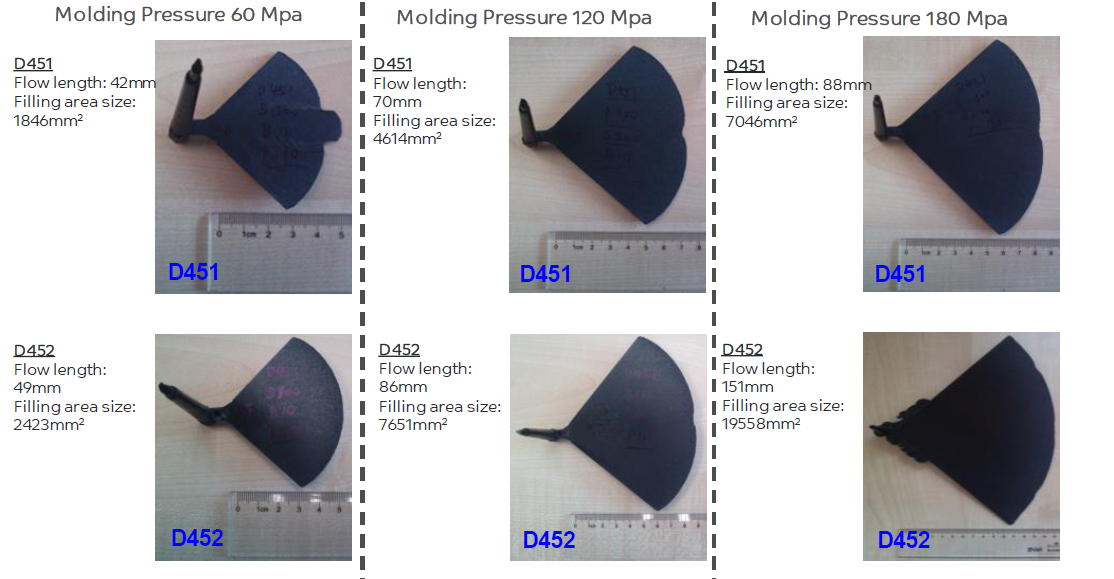

LNP™ THERMOCOMP™ D452 COMPOUND FLOW CAPABILITY COMPARISON:

FLOW LENGTH @ 0.8MM VS. THERMOCOMP™ D451 COMPOUND

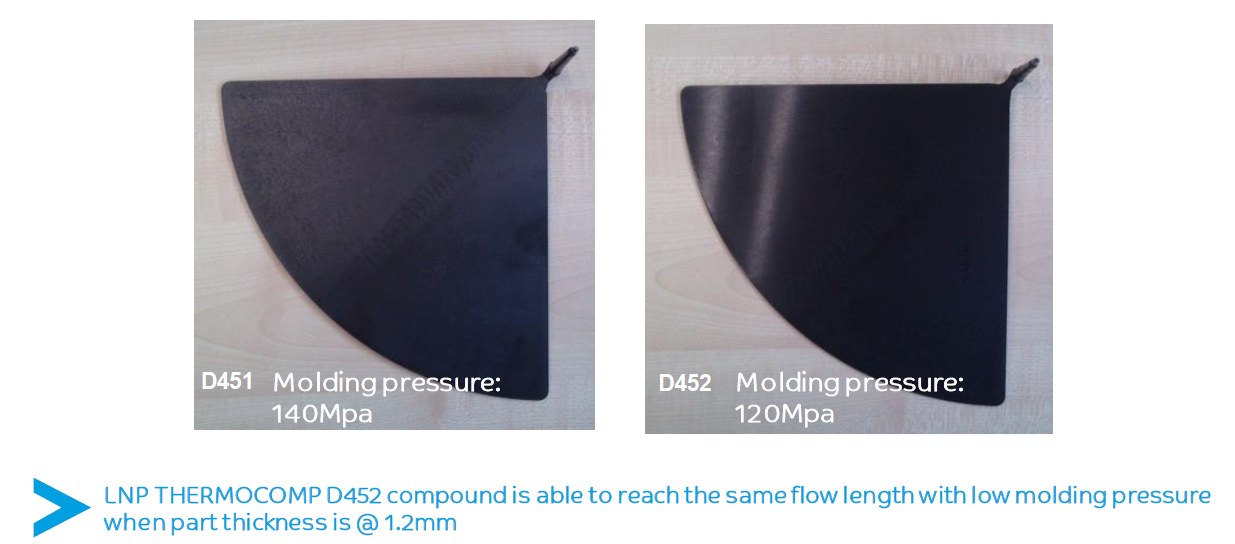

LNP™ THERMOCOMP™ D452 COMPOUND FLOW CAPABILITY COMPARISON:

FLOW LENGTH @ 1.2 MM VS. LNP TM THERMOCOMP™ D451 COMPOUND

LNP™ THERMOCOMP™ DF00A1I COMPOUND

LNP™ THERMOCOMP™ DF00A1I COMPOUND

LNP THERMOCOMP DF00A1I compound is a 50% glass fiber reinforced PC based resin grade with high modulus, low warpage, good ductility, easy flow, non-brominated, non-chlorinated UL94 V0 @ 1.0mm

Value Proposition

• Easy flow

• High modulus for thin wall applications

• Excellent impact resistance

• Excellent warpage control

• Non-Br, non-Cl thin wall flame resistance

• Hydro-thermal aging stability

• Good surface

Potential Applications

• Notebook PC, tablet and other consumer electronics device parts need high flow and high modulus

• Structural parts in other industrial segments

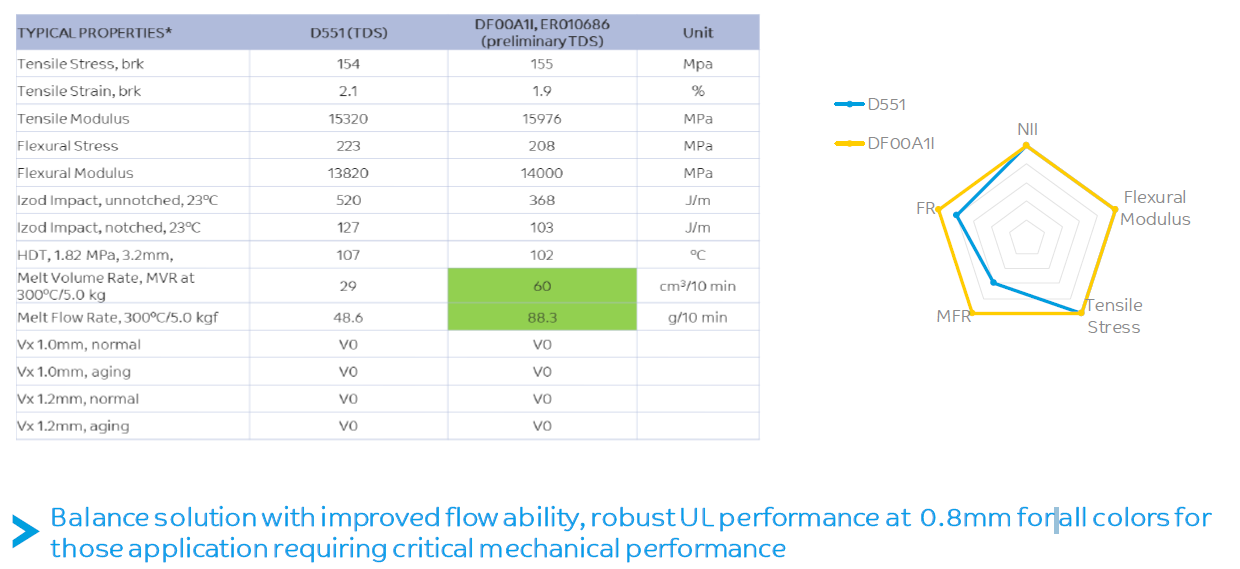

PERFORMANCE COMPARISON BETWEEN THERMOCOMP™ DF00A1I AND D551

LNP™ THERMOCOMP™ DC0041, DC0051, DC0041PD AND DC0041PE COMPOUND

LNP™ THERMOCOMP™ DC0041PD COMPOUND

LNP THERMOCOMP DC0041PD compound is a 20% PIR carbon fiber reinforced PC based resin grade with non-brominated, non-chlorinated UL94 V0 @ 0.8mm

Features

• Ultra modulus for thin wall applications

• Low density for light weight solution

• Good flow to fill thin wall part

• Good ductility

• Thin wall flame resistance to meet UL safety requirement

Potential Applications

• Portable computer hard disk drive door

• Structural parts for consumer electronic devices

• Structural parts in other industrial segments

• Drone interior component

LNP™ THERMOCOMP™ DC0041 COMPOUND

LNP THERMOCOMP DC0041 compound is a 22% PIR carbon fiber reinforced PC-based resin grade with non-brominated, non-chlorinated UL94 V0 @ 0.8mm

Features

• Ultra modulus for thin wall applications

• Low density for light weight solution

• Good flow to fill thin wall part

• Good ductility

• Thin wall flame resistance to meet UL safety requirement

Potential Applications

• Portable computer hard disk drive door

• Structural parts for consumer electronic devices

• Structural parts in other industrial segments

• Drone interior component

LNP™ THERMOCOMP™ DC0051 COMPOUND

LNP THERMOCOMP DC0051 compound is a 25% carbon fiber reinforced PC based resin grade

with non-brominated, non-chlorinated UL94 V0 @ 0.8mm

Features

• Ultra modulus for thin wall applications

• Low density for light weight solution

• Good flow to fill thin wall part

• Good ductility

• Thin wall flame resistance to meet UL safety requirement

Potential Applications

• Portable computer hard disk drive door

• Structural parts for consumer electronic devices

• Structural parts in other industrial segments

• Drone interior component

LNP™ THERMOCOMP™ DC0041PE COMPOUND

LNP THERMOCOMP DC0041PE compound is a PCR PC and 20% carbon fiber reinforced PC-based resin grade with non-brominated, non-chlorinated UL94 V0 @ 1.0 mm

Features

• Ultra modulus for thin wall applications

• Low density for light weight solution

• Good flow to fill thin wall part

• Good ductility

• Thin wall flame resistance to meet UL safety requirement

• PCR 30%

• Bio based is available

Potential Applications

• Portable computer hard disk drive door

• Structural parts for consumer electronic devices

• Structural parts in other industrial segments

• Drone interior component

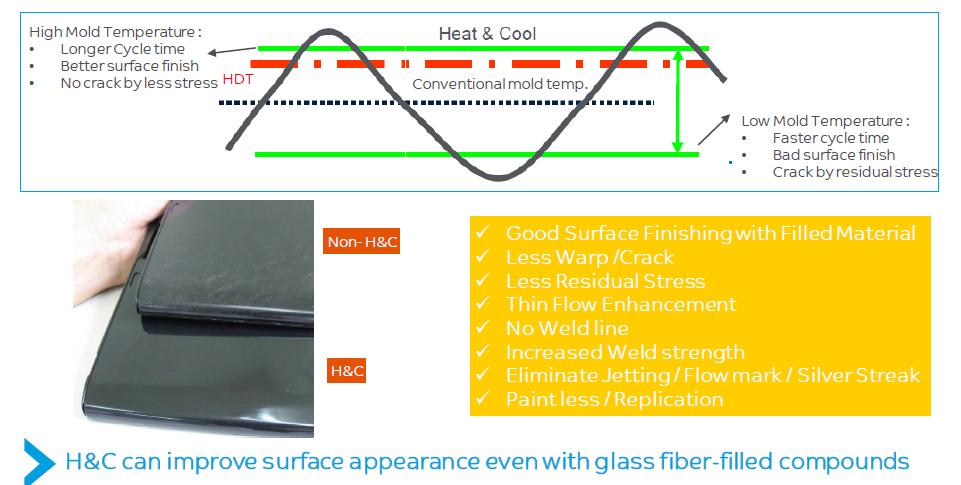

SURFACE QUALITY – USING HEAT & COOL TECHNOLOGY

• Heat & Cool = increase and decrease the tool temp within the cycle time.

• Heat & Cool technology can produce excellent surface appearance in molded parts.

• Mold temperature is key factor to affect product quality and cost.

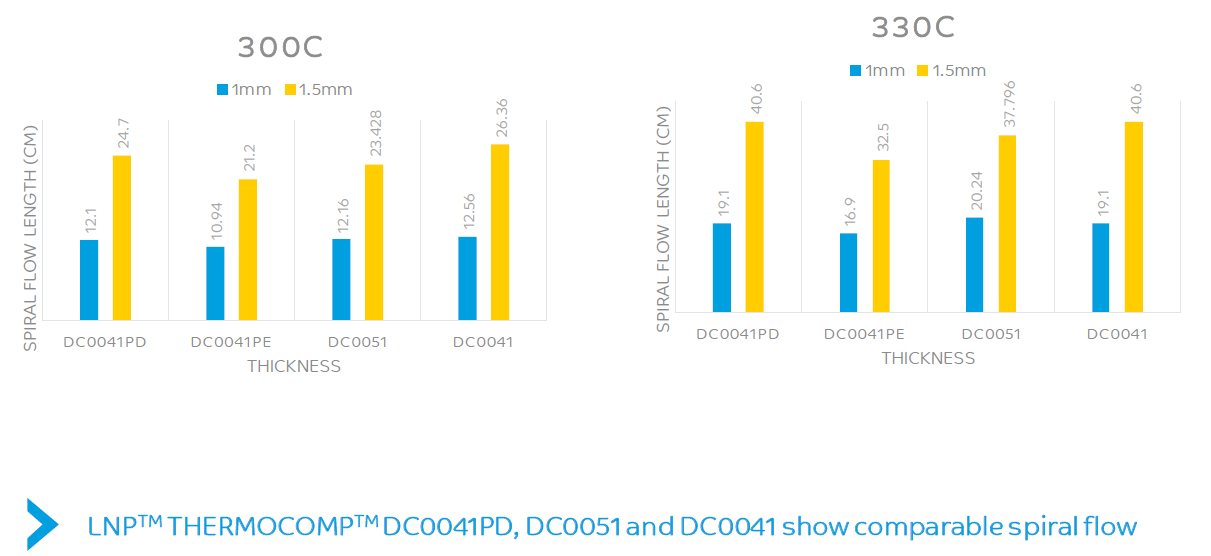

SPIRAL FLOW ANALYSIS

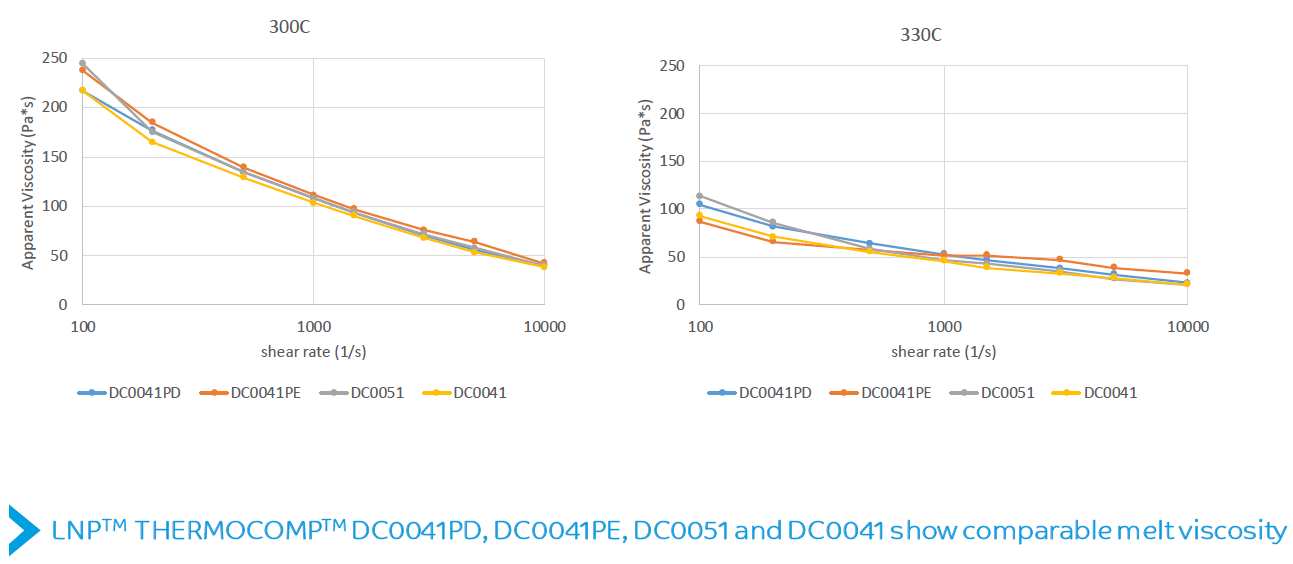

MELT VISCOSITY

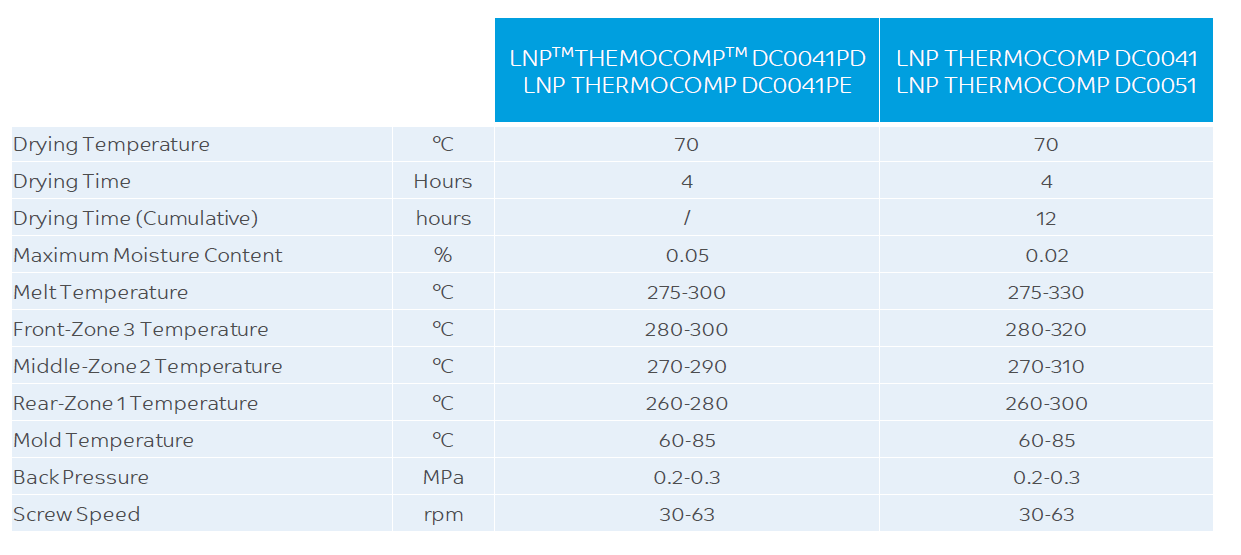

PROCESSING GUIDELINE

LNP™ PCR HIGH MODULUS DUCTILE PORTFOLIO

LNP™ THERMOCOMP™ D151RCC INTRODUCTION

LNP THERMOCOMP D151RCC compound is a colourable, 10% glass fiber filled, 50% PCR, non Chlorinated, non Brominated FR UL94 V0@0.8mm Copolymer PC Compound

Features:

• Comparable mechanical properties as virgin D151

• Good color ability

• Super thin wall FR performance

• Outstanding surface quality

• Excellent warpage control

• High flow ability

• Good impact strength

Potential Applications:

• Mobile phone and the parts requiring green/environmental protection concept and color ability in other consumer electronics devices

• Various applications in non Consumer Electronics industry requiring green/environmental protection concept, color ability, super thin wall FR and the good balance of modulus, surface quality, dimensional stability, flow ability and ductility

LNP™ THERMOCOMP™ D451RCC INTRODUCTION

LNP THERMOCOMP D451RCC compound

is a colourable, 40% glass fiber filled, 35% PCR, non Chlorinated, non Brominated FR UL94 V0@0.6mm Copolymer PC Compound

Features:

• Comparable mechanical properties as virgin D451

• Good color ability

• Super thin wall FR performance

• Excellent warpage control

• High flow ability

• Good impact strength

• High modulus

Potential Applications:

• Notebook and the parts requiring green/environmental protection concept and color ability in other consumer electronics devices

• Various applications in non Consumer Electronics industry requiring green/environmental protection concept, color ability, super thin wall FR and the good balance of modulus, surface quality, dimensional stability, flow ability ductility , and high modulus

LNP™ THERMOCOMP™ D551RCC INTRODUCTION

LNP THERMOCOMP D551RCC compound is a colourable, 50% glass fiber filled, 25% PCR, non Chlorinated, non Brominated FR UL94 V0@1.0mm Copolymer PC Compound

Features:

• Comparable mechanical properties as virgin D551

• Thin wall FR performance

• Excellent warpage control

• High flow ability

• Good impact strength

• High modulus

Potential Applications:

• Notebook, Tablet PC and the parts requiring green/environmental protection concept and color ability in other consumer electronics devices

• Various applications in non Consumer Electronics industry requiring green/environmental protection concept, color ability, super thin wall FR and the good balance of modulus, surface quality, dimensional stability, flow ability ductility , and high modulus

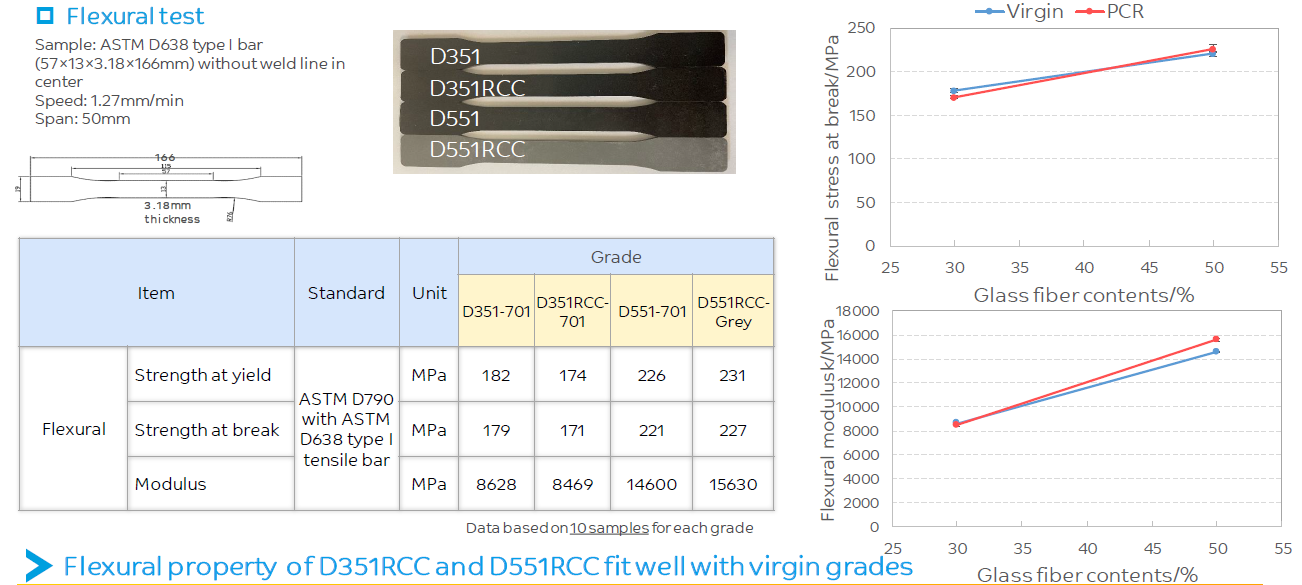

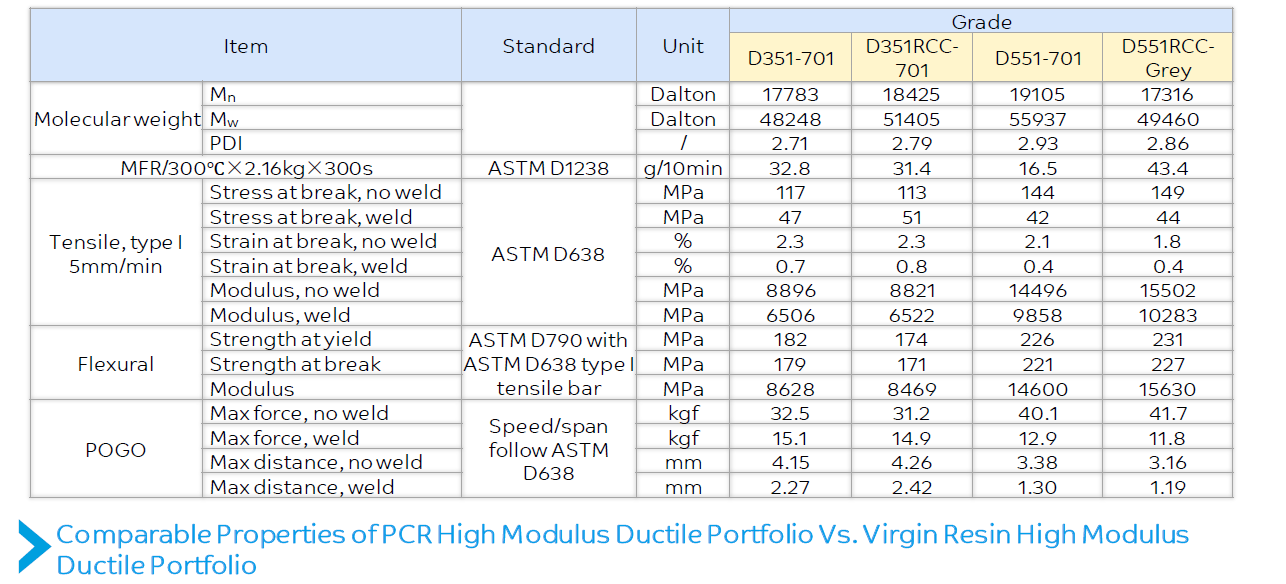

FLEXURAL PROPERTY OF PCR HIGH MODULUS DUCTILE PORTFOLIO VS. VIRGIN RESIN HIGH MODULUS DUCTILE PORTFOLIO

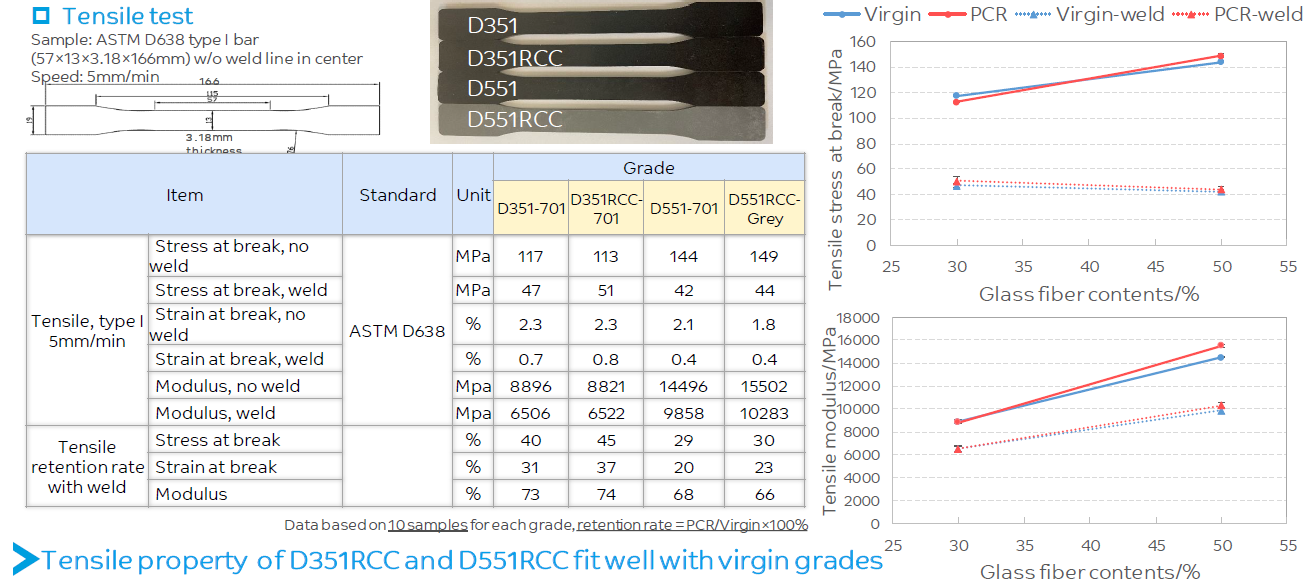

TENSILE PROPERTY OF PCR HIGH MODULUS DUCTILE PORTFOLIO VS. VIRGIN RESIN HIGH MODULUS DUCTILE PORTFOLIO

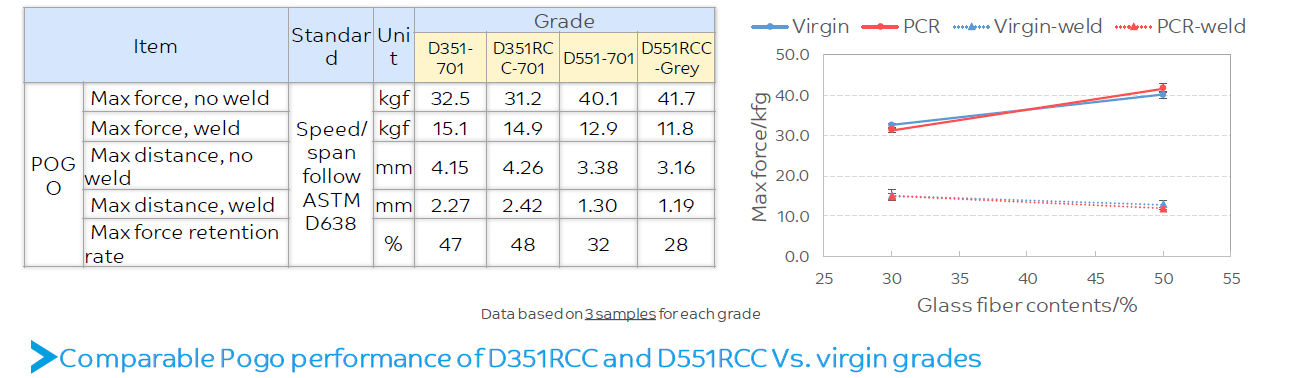

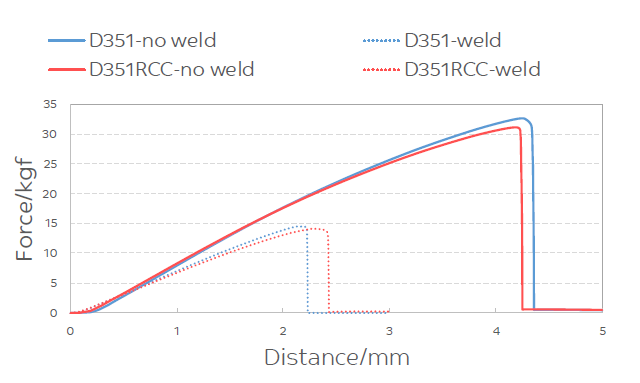

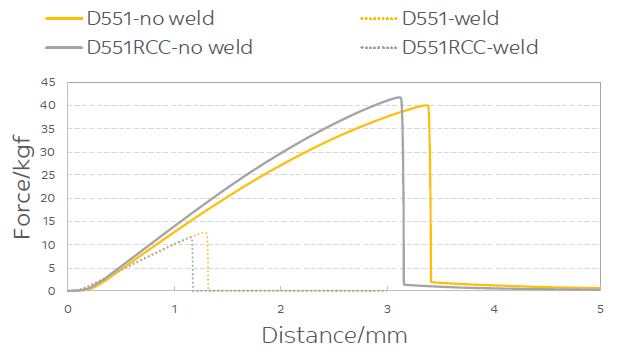

POGO PERFORMANCE OF PCR HIGH MODULUS DUCTILE PORTFOLIO VS. VIRGIN RESIN HIGH MODULUS DUCTILE PORTFOLIO

Device: Pogo Tester (9505S)

• Tip Diameter= 5.0 mm

• Max loading setting=45 kgf

• Max distance=15mm

• Span=50 mm

• Speed setting=1.27 mm/min

• Follow ASTM D790 flexural test condition

POGO TEST LOAD DISTANCE CURVE OF PCR HIGH MODULUS DUCTILE PORTFOLIO VS. VIRGIN RESIN HIGH MODULUS DUCTILE PORTFOLIO

THERMOCOMP™ D351 and D351RCC

In low force area, curve of PCR grade fits well with virgin grade.

Virgin grade has higher max force w/o weld line, corresponding to tensile/flexural test.

THERMOCOMP™ D551/D551RCC

PCR grade without weld line has higher force at same distance compared to virgin grade resulting from higher modulus.

PCR grade with weld line has lower max force which is different to tensile test.

SUMMARY OF PCR HIGH MODULUS DUCTILE PORTFOLIO VS. VIRGIN RESIN HIGH MODULUS DUCTILE PORTFOLIO

DISCLAIMER

DISCLAIMER: THE MATERIALS, PRODUCTS AND SERVICES OF SAUDI BASIC INDUSTRIES CORPORATION (SABIC) OR ITS SUBSIDIARIES OR AFFILIATES (“SELLER”) ARE SOLD SUBJECT TO SELLER’S STANDARD CONDITIONS OF SALE, WHICH ARE AVAILABLE UPON REQUEST. INFORMATION AND RECOMMENDATIONS CONTAINED IN THIS DOCUMENT ARE GIVEN IN GOOD FAITH. HOWEVER, SELLER MAKES NO EXPRESS OR IMPLIED REPRESENTATION, WARRANTY OR GUARANTEE ( i ) THAT ANY RESULTS DESCRIBED IN THIS DOCUMENT WILL BE OBTAINED UNDER END USE CONDITIONS, OR (ii) AS TO THE EFFECTIVENESS OR SAFETY OF ANY DESIGN OR APPLICATION INCORPORATING SELLER’S MATERIALS, PRODUCTS , SERVICES OR RECOMMENDATIONS. UNLESS OTHERWISE PROVIDED IN SELLER’S STANDARD CONDITIONS OF SALE, SELLER SHALL NOT BE RESPONSIBLE FOR ANY LOSS RESULTING FROM ANY USE OF ITS MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS DESCRIBED IN THIS DOCUMENT. Each user is responsible for making its own determination as to the suitability of Seller’s materials, products, services or recommendations for the user’s particular use through appropriate end use and other testing and analysis. Nothing in any document or oral statement shall be deemed to alter or waive any provision of Seller’s Standard Conditions of Sale or this Disclaimer, unless it is specifically agreed to in a writing signed by Seller. Statements by Seller concerning a possible use of any material, product, service or design do not, are not intended to, and should not be construed to grant any license under any patent or other intellectual property right of Seller or as a recommendation for the use of any material, product, service or design in a manner that infringes any patent or other intellectual property right.

SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates, unless otherwise noted.

© 2023 Saudi Basic Industries Corporation (SABIC). All Rights Reserved.

Any brands, products or services of other companies referenced in this document are the trademarks, service marks and/or trade names of their respective holders.

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

DISCLAIMER: THE MATERIALS, PRODUCTS AND SERVICES OF SAUDI BASIC INDUSTRIES CORPORATION (SABIC) OR ITS SUBSIDIARIES OR AFFILIATE S (“SELLER”) ARE SOLD SUBJECT TO SELLER’S STANDARD CONDITIONS OF SALE, WHICH ARE AVAILABLE UPON REQUEST. INFORMATION AND RECOMMENDATIONS CONTAINED IN THIS DOCUMENT ARE GIVEN IN GOOD FAITH. HOWEVER, SELLER MAKES NO EXPRESS OR IMPLIED REPRESENTATION, WARRANTY OR GUARANTEE ( i ) THAT ANY RESULTS DESCRIBED IN THIS DOCUMENT WILL BE OBTAINED UNDER END USE CONDITIONS, OR (ii) AS TO THE EFFECTIVENESS OR SAFETY OF ANY DESIGN OR APPLICATION INCORPORATING SELLER’S MATERIALS, PRODUCTS , SERVICES OR RECOMMENDATIONS. UNLESS OTHERWISE PROVIDED IN SELLER’S STANDARD CONDITIONS OF SALE, SELLER SHALL NOT BE RESPONSIBLE FOR ANY LOSS RESULTING FROM ANY USE OF ITS MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS DESCRIBED IN THIS DOCUMENT. Each user is responsible for making its own determination as to the suitability of Seller’s materials, products, serv ices or recommendations for the user’s particular use through appropriate end use and other testing and analysis. Nothing in any document or oral statement shall be deemed to alter or waive any provision of Seller’s Standard Conditions of Sale or this Disclaimer, unless it is specifically agreed to in a writing signed by Seller. Statements by Seller concerning a possible use of any material, product, service or design do not, are not intended to, and should not be construed to grant any license under any patent or other intellectual property right of Seller or as a recommendation for the use of any material, product, service or design in a manner that infringes any patent or other intellectual property right.

SABIC and brands marked with ™ are trademarks of SABIC or its subsidiaries or affiliates, unless otherwise noted.

© 2023 Saudi Basic Industries Corporation (SABIC). All Rights Reserved.

Any brands, products or services of other companies referenced in this document are the trademarks, service marks and/or trade names of their respective holders.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience