AN INTRODUCTION OF LNP™ LDS SOLUTION

• LDS Basic Introduction

• LNP TM LDS Product Portfolio Introduction & Features

• The Introduction of Newly Commercialized LDS Grades

• LDS Recommended Processing Guideline

• Case Study

LDS BASIC CONCEPT

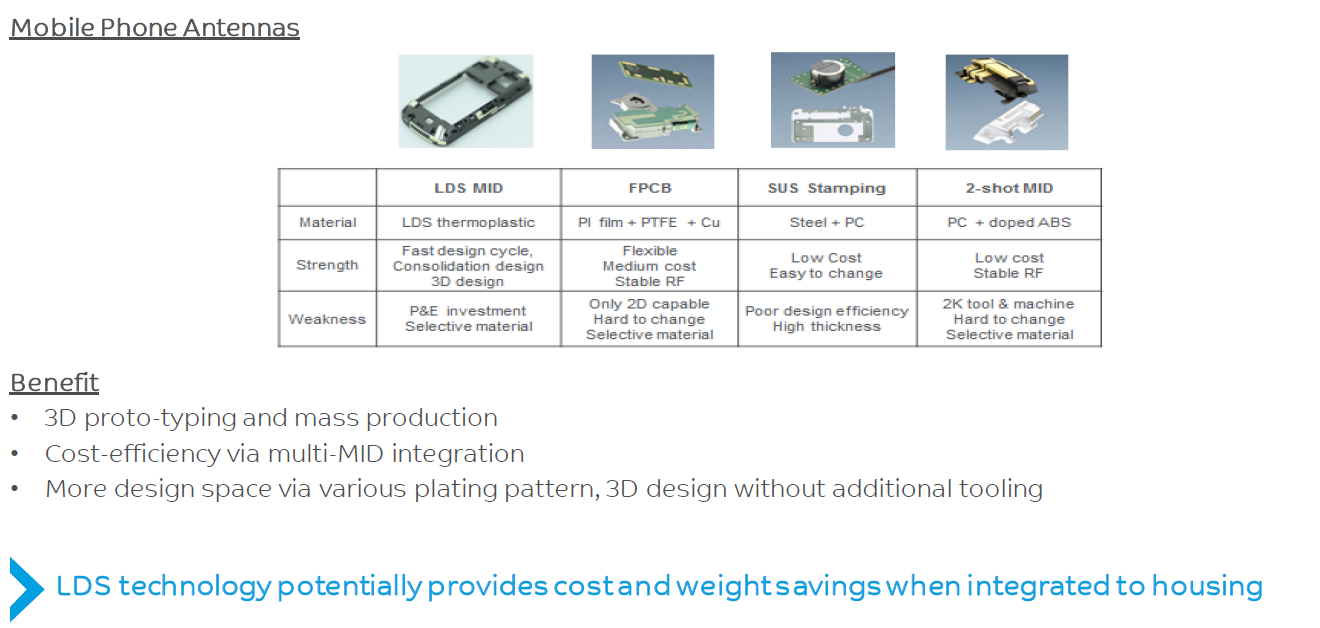

Selective metallization of thermoplastics injection molded parts by Laser Direct Structuring

LPKF developed Molded Interconnect Device (MID) technology in 1997 as a laser based procedure for the production of MIDs, called the LPKF LDS Process.

Benefits of LDS:

• Full 3D Capability - System Integration

• Fast and easy design changes - speed to market

• No layout specific tooling - lower cost

• Fine pitch resolution - miniaturization

• High cost efficiency - fine structure and small production

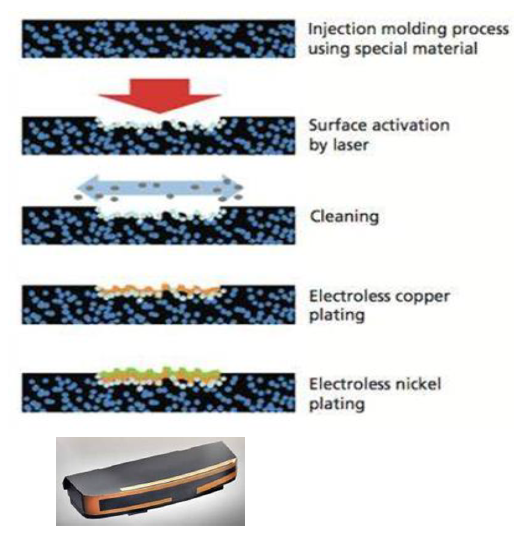

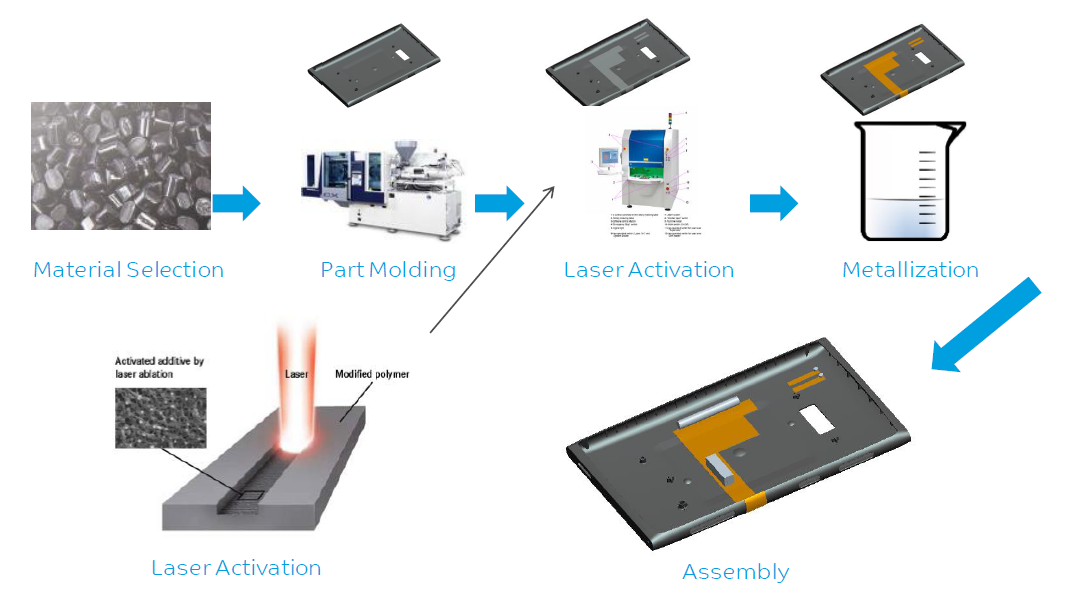

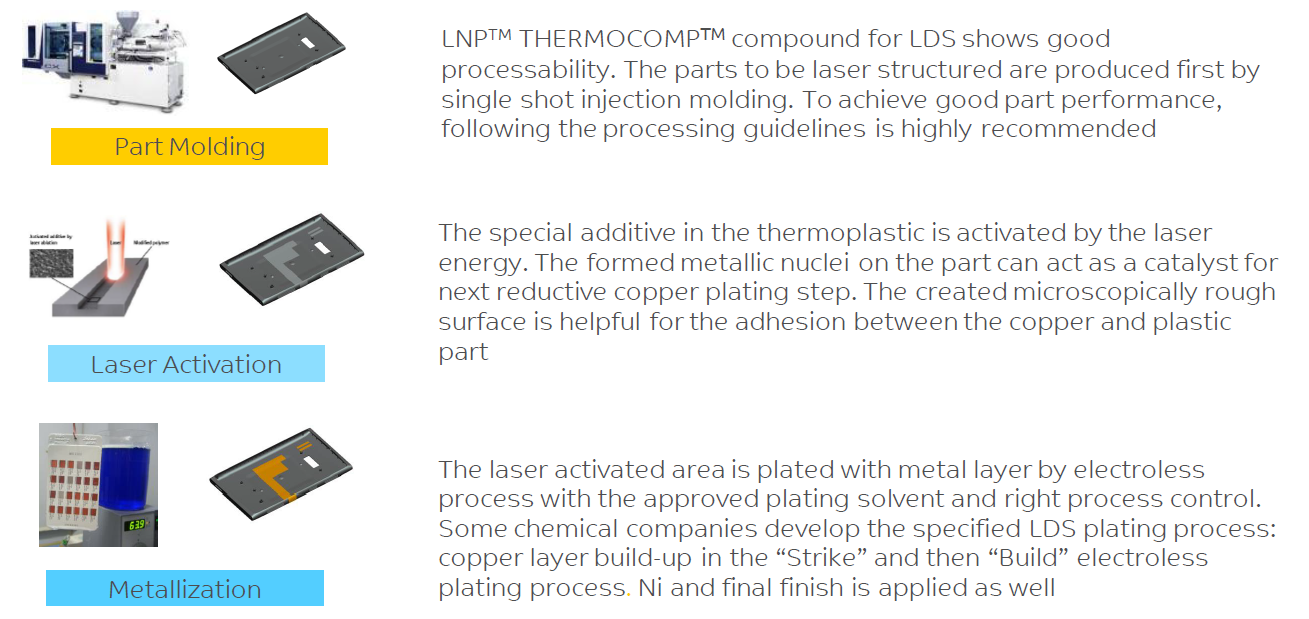

LDS BASIC PROCESS

LDS PROCESS INTRODUCTION

LPKF LDS PROCESS VALUE PROPOSITION

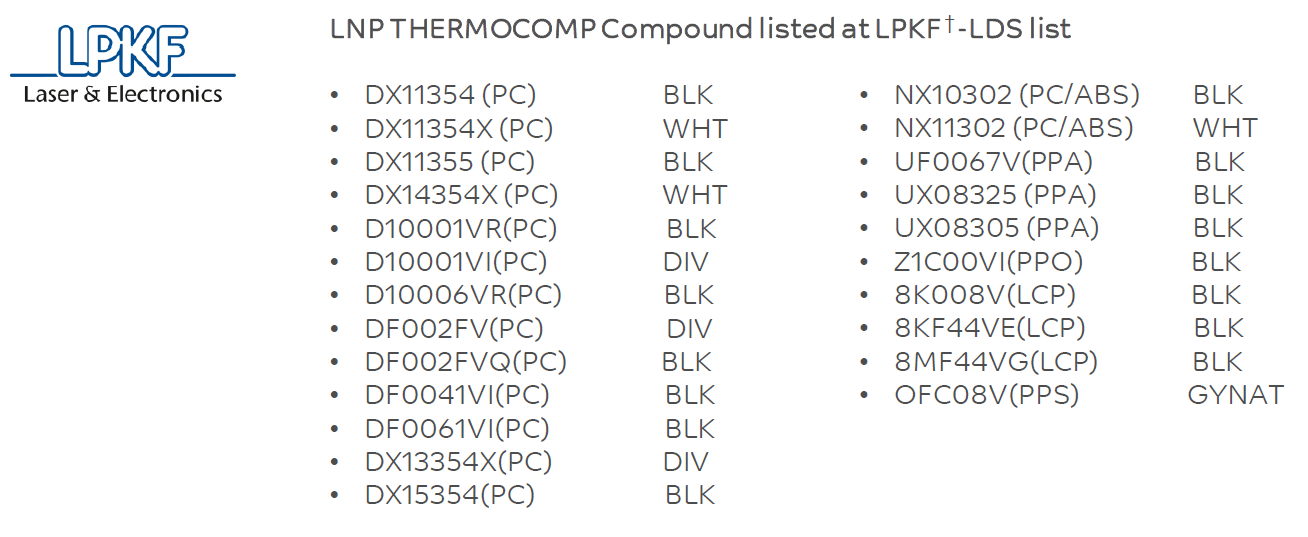

LNP™ THERMOCOMP™ LDS COMPOUNDS

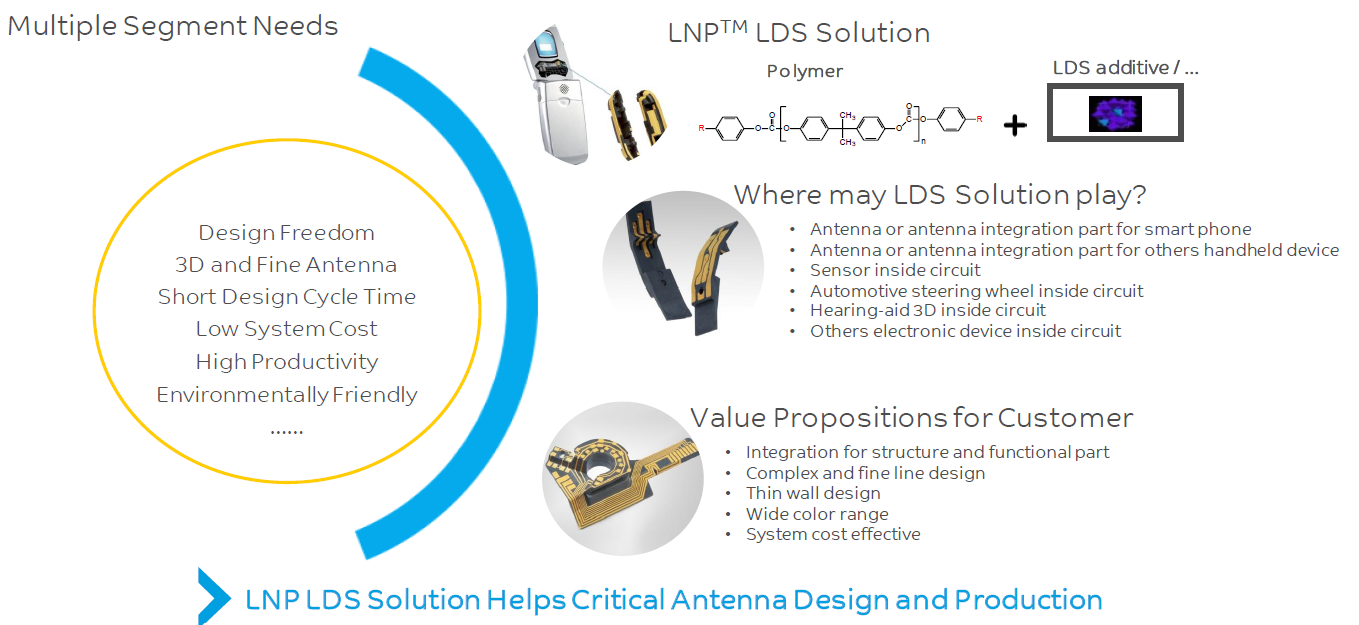

LNP™ LDS SOLUTION INTRODUCTION

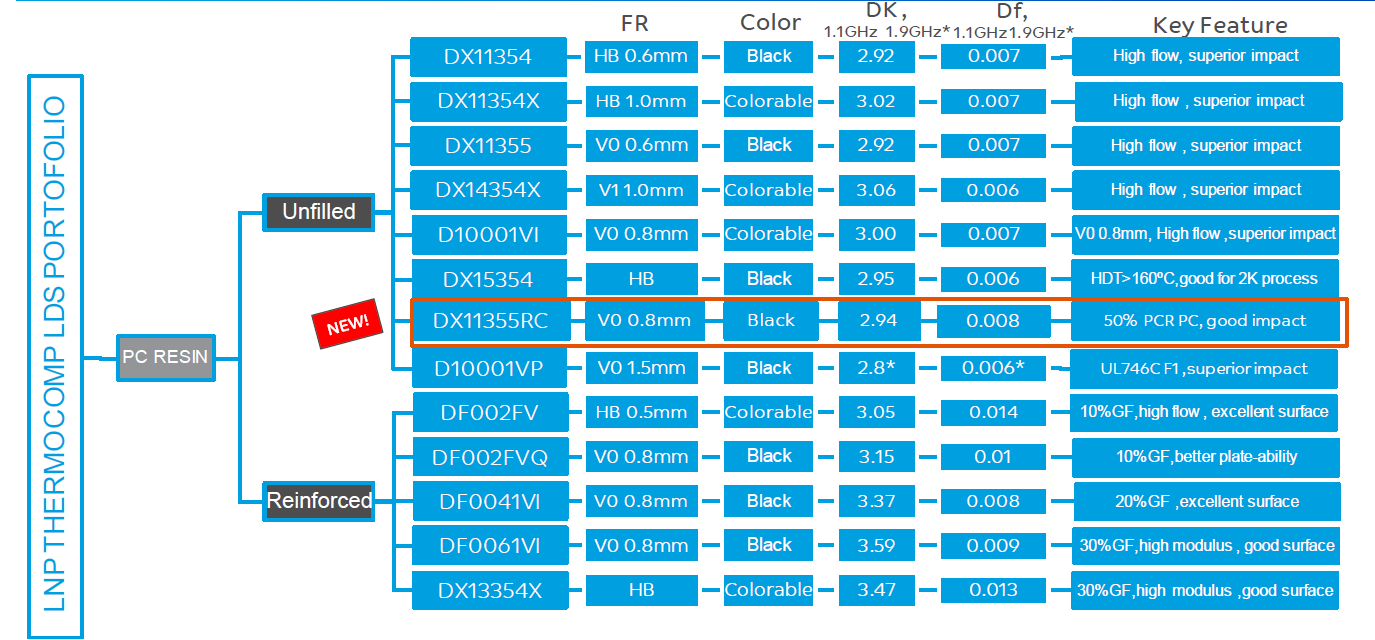

LNP™ THERMOCOMP™ LDS PORTFOLIO - 1

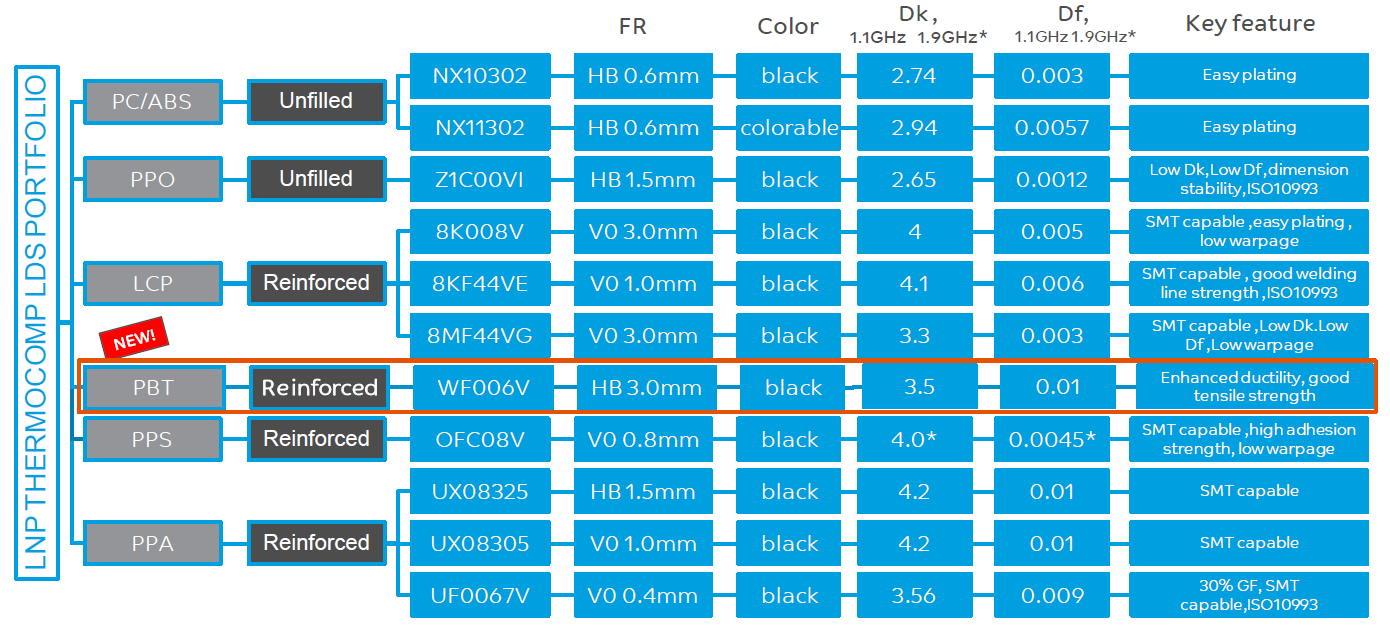

LNP™ THERMOCOMP™ LDS PORTOFOLIO BEYOND PC BASE

LNP™ THERMOCOMP™ COMPOUND LDS GRADE DATA SHEET

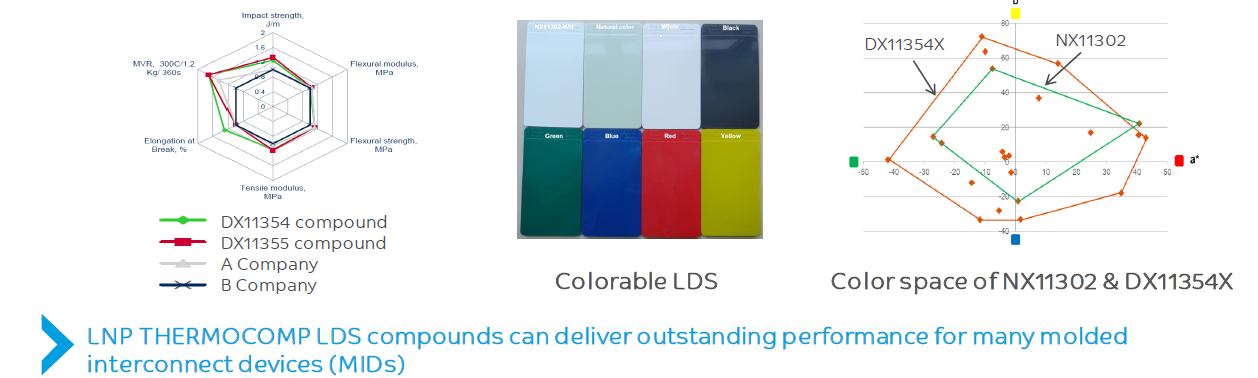

LNP™ THERMOCOMP™ LDS PORTFOLIO VALUE PROPOSITION

LNP THERMOCOMP LDS Compounds Can Provide:

• High flow with superior impact performance with UL94 V 0 rating down to 0.6 mm (PC base resin)

• Wide color space with patented technology

• More complete portfolio

• Various Dk/Df LDS grades for different applications requiring good dielectric properties

• High stiffness and modulus with good aesthetics

• High heat material for lead free soldering with UL94 V 0 rating down to 0.4 mm

THE INTRODUCTION OF NEWLY COMMERCIALIZED LDS GRADES

LNP™ THERMOCOMP™ D10001VP(ER008312) INTRODUCTION

LNP THERMOCOMP D10001VP(ER008312) is a PC based non Chlorinated and non Brominated FR UL94 V0 1.5mm for Laser Direct Structuring application

Features:

• Robust FR performance

• UL 746C F1

• High impact strength under low temperature

• Good process ability

• UL94V0

Potential Applications:

• Outdoor application requiring UV exposure and water immersion

• Circuit replacement requiring fine pitch and 3D pattern

• Other applications requiring LDS capable, high impact , UL 746C F1 and UL94 V0

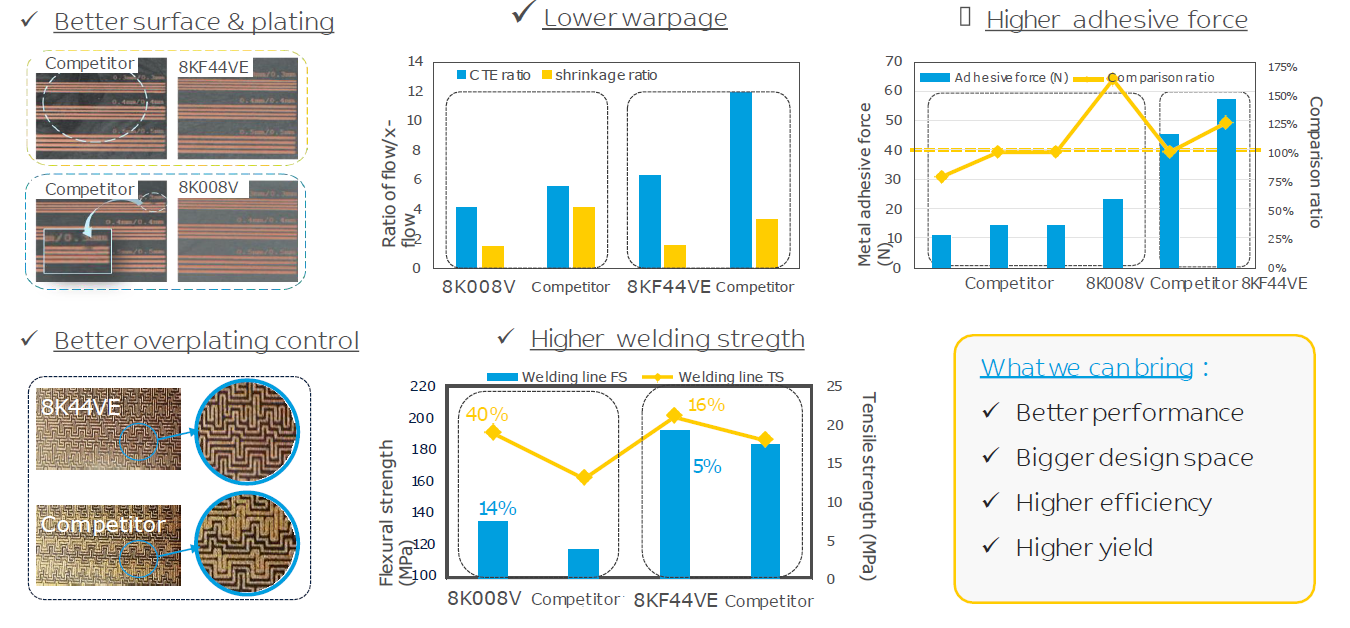

LNP™ THERMOCOMP™ 8K008V (ER010182) INTRODUCTION

LNP THERMOCOMP 8K008V(ER010182) is Liquid Crystalline Polymer (LCP) based compound for Laser Direct Structuring application

Features:

• High heat resistance for SMT processing

• Smooth surface

• Low Warpage

• Stable dielectric performance

• Easy plating

• UL94V0

Potential Applications:

• Optical communication module , 5G AAU dipole , OIS VCM , Antenna for laptop and wearable device , Endoscope antenna, POS security module

LNP™ THERMOCOMP™ 8MF44VE (ER010302) INTRODUCTION

LNP THERMOCOMP 8MF44VE (ER010302) is a Liquid Crystalline Polymer (LCP) based compound for Laser Direct Structuring application

Features:

• High heat resistance for robust SMT processing

• High adhesion strength

• Good welding line strength

• Low warpage

• Easy plating

• UL94V0

Potential Applications:

• Optical communication module, 5G AAU dipole , OIS VCM , Antenna for laptop and wearable device , Endoscope antenna, POS security module

LNP™ 8K008V / 8KF44VE PERFORMANCE AND VALUE PROPOSITION

LNP™ THERMOCOMP™ 8MF44VG (ER010710) INTRODUCTION

LNP THERMOCOMP 8MF44VG (ER010710) is a Liquid Crystalline Polymer (LCP) based compound for Laser Direct Structuring application

Features:

• High heat resistance for robust SMT processing

• Smooth surface

• DK 3.2 / Df 0.003

• Low warpage

• UL94 V0

Potential Applications:

• Laptop antenna is requested low Dk and Low Df , SMT capable , LDS , High flow , and Halogen FR V0

• Wearable device antenna

LNP™ THERMOCOMP™ OFC08V (ER011248) INTRODUCTION

LNP THERMOCOMP OFC08V (ER011248) is a PPS based with glass fiber reinforced compound for Laser Direct Structuring application

Features:

• High heat resistance for SMT processing

• High modulus and strength

• Good impact strength and ductility

• Excellent heat and chemical resistance

• UL94 V0

• Good flash control

Potential Applications:

• 5G dipole antenna ,Electric and electronic components , and various parts requiring high strength and high heat resistance

LNP™ THERMOCOMP™ DX11355RC(ER009131) INTRODUCTION

LNP THERMOCOMP DX11355RC(ER009131) compound is based on recycled Polycarbonate (PC) resin. Added features of this grade include: Good Surface, Good Ductility, Non Brominated & Non Chlorinated Flame Retardant. Post Consumer Recycling (PCR) Polycarbonate content up to 50% for Laser Direct Structuring application

Features:

• Flame retardant

• Post Consumer Recycled (PCR)

• Non Brominated, Non Chlorinated

• Laser Direct Structuring

Potential Applications:

• Personal accessory

• Electrical devices and displays, Electrical components and infrastructure

LNP™ THERMOCOMP™ WF006V (ER010941) INTRODUCTION

LNP THERMOCOMP WF006V compound is a 30% glass fiber reinforced PBT resin based LDS material solution with good plating and stable RF performance. Wide processing window makes it a good candidate for internal and external parts for Laser Direct Structuring applications.

Features:

• Chemical Resistance

• High Heat Resistance

• Good Tensile Strength

• Enhanced Ductility

• Low warpage

Potential Applications:

• Smart phone antenna , Wearable device antenna, Animal tracker

PROCESSING GUIDE

- DESIGN GUIDE & INJECTION TROUBLESHOOTING

- LASER ACTIVATION PLATING

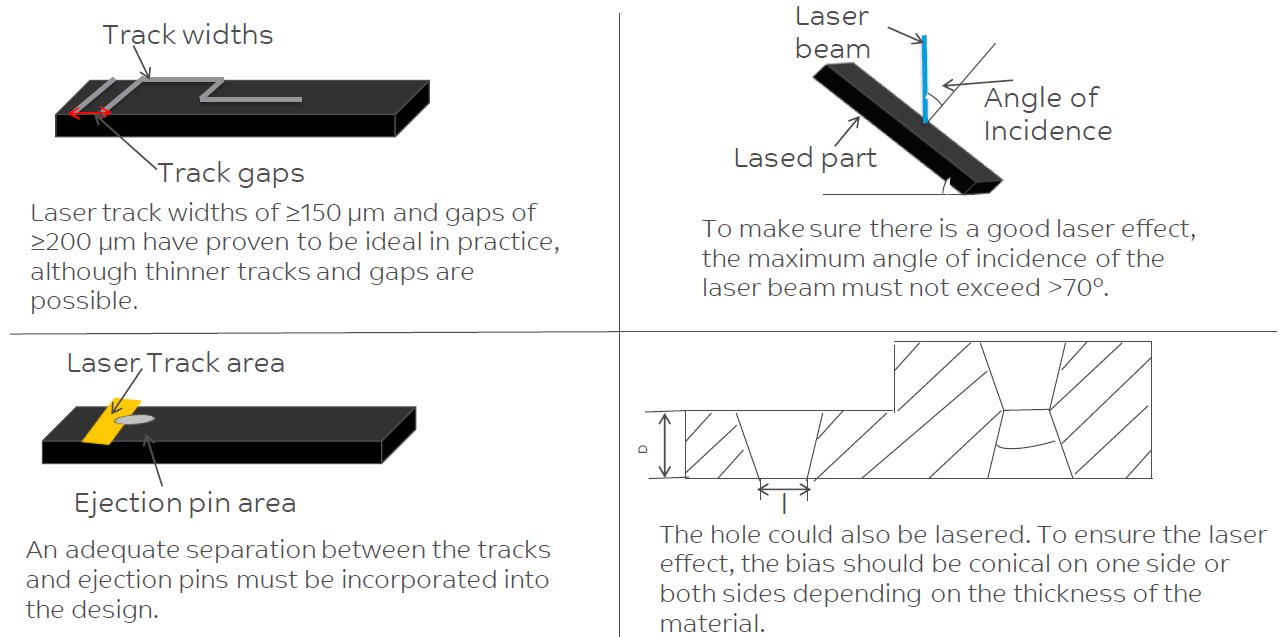

LDS DESIGN GUIDELINES (SUMMARY)

• Avoid using aluminum based tool for LDS material injection

• Sharp edged transition around the metallization structure should be avoided

• Avoid injection point and ejector locating around the metallization area

• Avoid gate & weld line on metallization area

• Flow mark & gas trap should not be on metallization area.

• Silicon based mold releasing agent should not be used during injection

• With GF filled grade, must follow general rules to minimize glass floating on surface

• Choose the optimal material based on the application and follow the processing guidelines

• Material recycling must be prevented

LDS DESIGN GUIDELINES

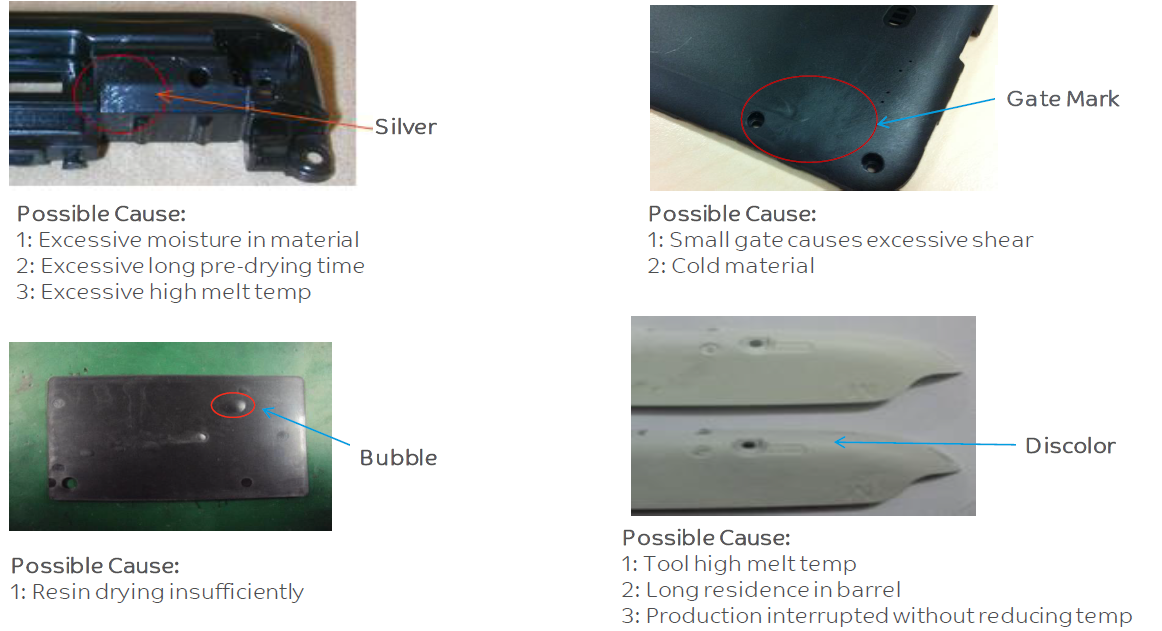

TROUBLE SHOOTING

LASER ACTIVATION PLATING

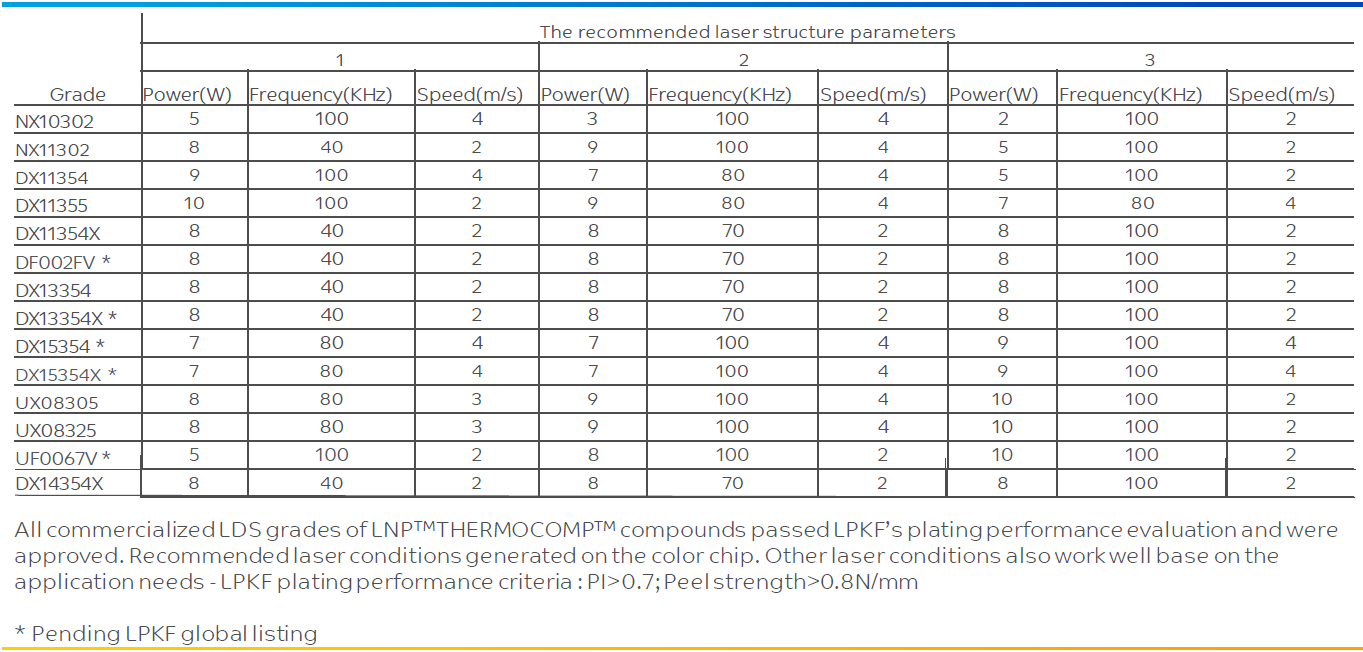

RECOMMENDED LASER OPERATING PARAMETERS

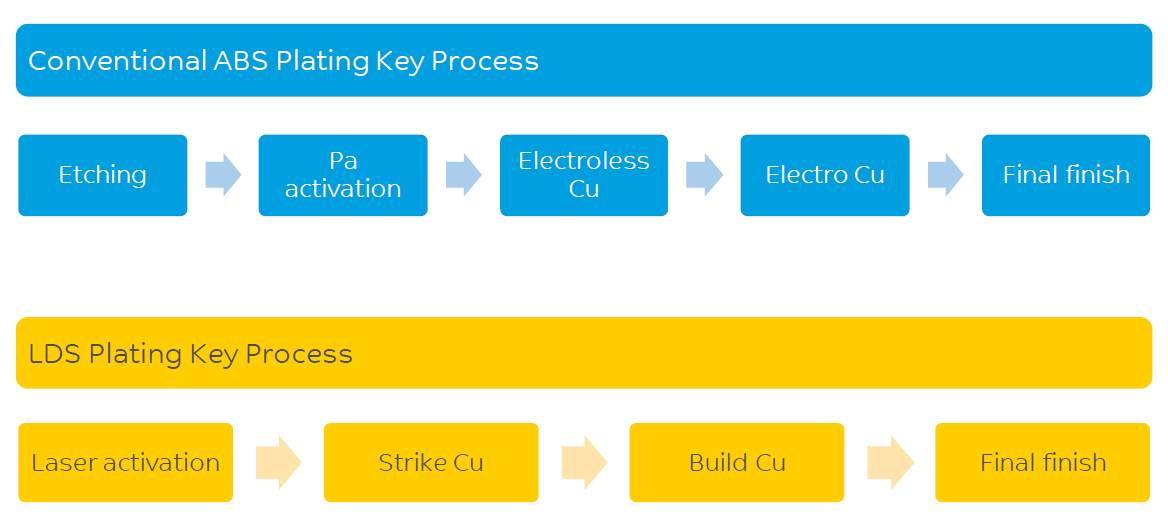

PLATING PROCESS COMPARISON

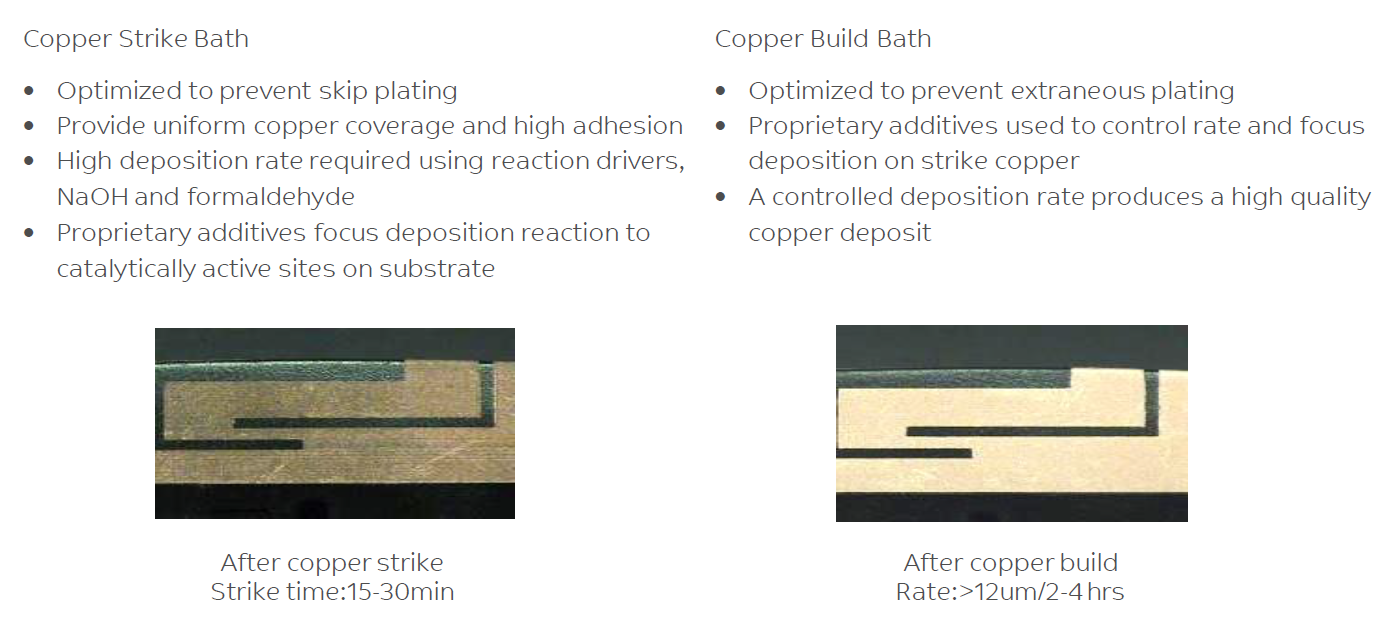

MACDERMID MID COPPER 100 XD PLATING SOLUTION

CASE STUDY

CASE STUDY - LNP™ THERMOCOMP™ DX13354 IN SMART WATCH ANTENNA

Application: Smart watch antenna and cover integration part

Application Requirements

• Good balance of modulus and impact

• Good dimension stability, especially after painting

• Good surface

Value Proposition By Using DX13354

• Integration design for various antenna, structure part and circuit

• Lower cost

• Simplify assembly process

PRODUCTS AND GRADES

CONTACT US

Reach out to us for one-on-one support to ensure you have all the information and insights you need to choose the best-fit material for your application.

DISCLAIMER: THE MATERIALS, PRODUCTS AND SERVICES OF SAUDI BASIC INDUSTRIES CORPORATION (SABIC) OR ITS SUBSIDIARIES OR AFFILIATE S (“SELLER”) ARE SOLD SUBJECT TO SELLER’S STANDARD CONDITIONS OF SALE, WHICH ARE AVAILABLE UPON REQUEST. INFORMATION AND RECOMMENDATIONS CONTAINED IN THIS DOCUMENT ARE GIVEN IN GOOD FAITH. HOWEVER, SELLER MAKES NO EXPRESS OR IMPLIED REPRESENTATION, WARRANTY OR GUARANTEE ( i ) THAT ANY RESULTS DESCRIBED IN THIS DOCUMENT WILL BE OBTAINED UNDER END USE CONDITIONS, OR (ii) AS TO THE EFFECTIVENESS OR SAFETY OF ANY DESIGN OR APPLICATION INCORPORATING SELLER’S MATERIALS, PRODUCTS , SERVICES OR RECOMMENDATIONS. UNLESS OTHERWISE PROVIDED IN SELLER’S STANDARD CONDITIONS OF SALE, SELLER SHALL NOT BE RESPONSIBLE FOR ANY LOSS RESULTING FROM ANY USE OF ITS MATERIALS, PRODUCTS, SERVICES OR RECOMMENDATIONS DESCRIBED IN THIS DOCUMENT. Each user is responsible for making its own determination as to the suitability of Seller’s materials, products, serv ices or recommendations for the user’s particular use through appropriate end use and other testing and analysis. Nothing in any document or oral statement shall be deemed to alter or waive any provision of Seller’s Standard Conditions of Sale or this Disclaimer, unless it is specifically agreed to in a writing signed by Seller. Statements by Seller concerning a possible use of any material, product, service or design do not, are not intended to, and should not be construed to grant any license under any patent or other intellectual property right of Seller or as a recommendation for the use of any material, product, service or design in a manner that infringes any patent or other intellectual property right.

SABIC and brands marked with ™are trademarks of SABIC or its subsidiaries or affiliates, unless otherwise noted.

© 2023 Saudi Basic Industries Corporation (SABIC). All Rights Reserved.

Any brands, products or services of other companies referenced in this document are the trademarks, service marks and/or trade names of their respective holders.

Your PDF is downloading. Please wait.

Register for High value Multi-Point Data

- Access validated product data to streamline material selection

- Get inspired by innovative application ideas

- Register for high value multi-point data and a personalized experience